Super-junction device and manufacturing method thereof

A technology of superjunction device and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., and can solve problems such as soft breakdown and increased device leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

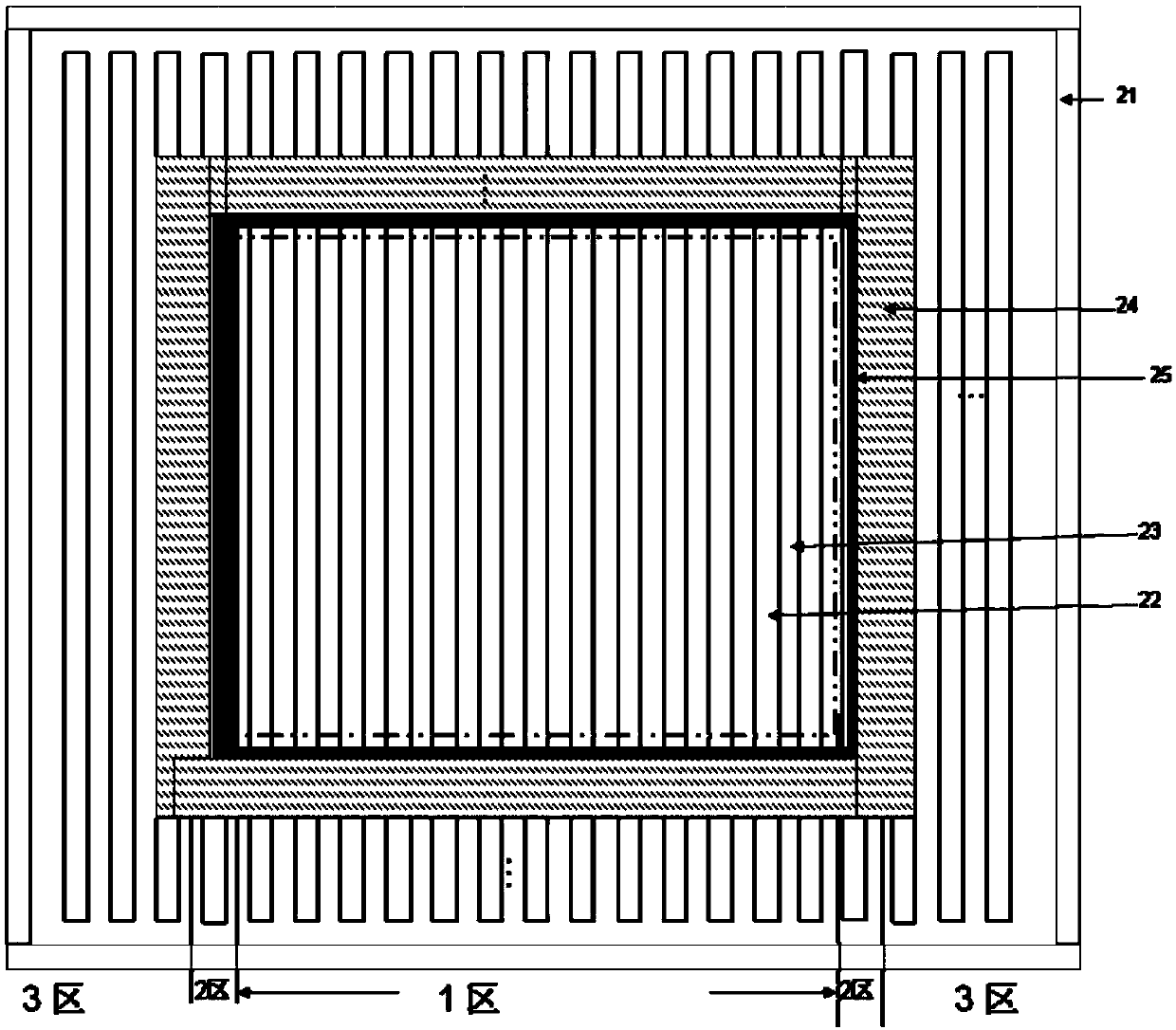

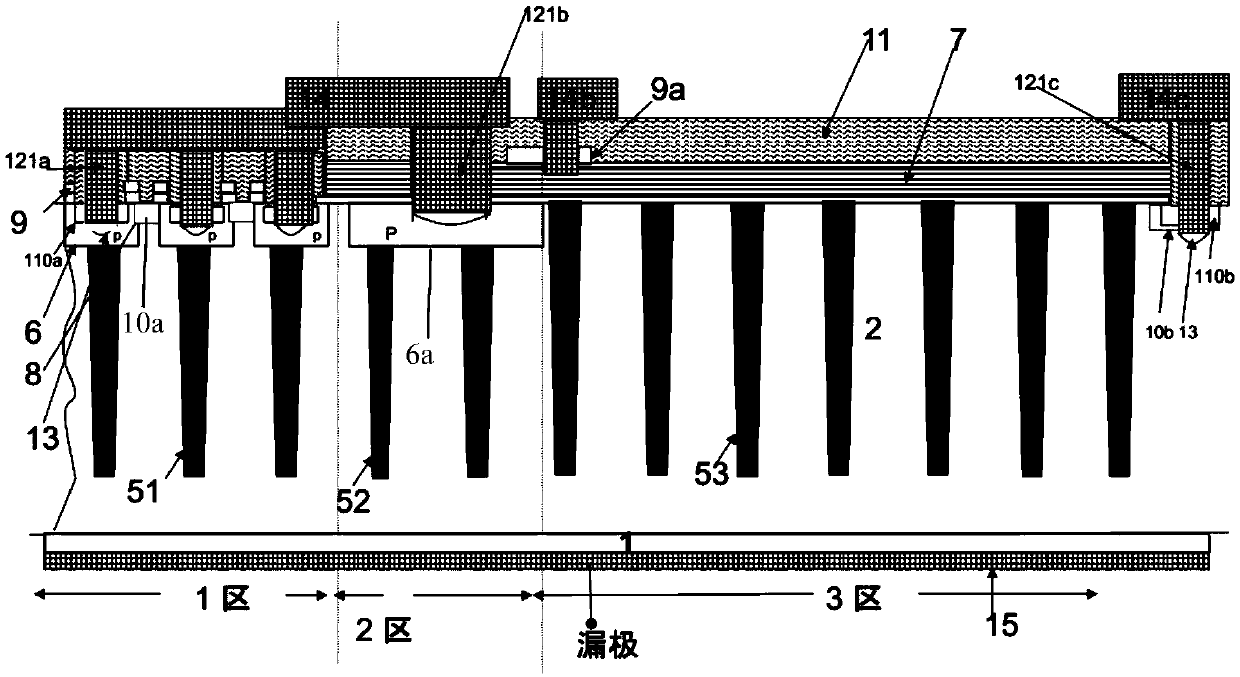

[0070] Such as figure 1 Shown is the top view of the superjunction device of the embodiment of the present invention; the general superjunction device structure includes a current flow region, a terminal region laterally subjected to a reverse bias voltage, and a transition region between the current flow region and the terminal region, a termination area surrounds the periphery of the current flow area, figure 1 Zone 1 represents the current flow region, Zone 2 represents the transition zone, and Zone 3 represents the terminal zone.

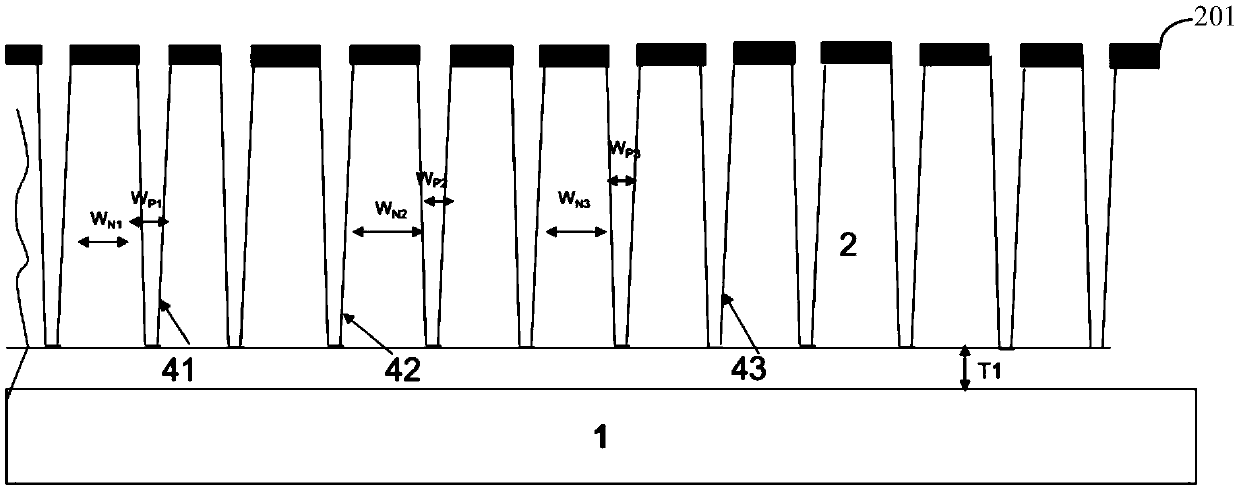

[0071] Zone 1 includes a super junction structure composed of alternately arranged P-type pillars 22 and N-type pillars 23, figure 1 Both the P-type pillars 22 and the N-type pillars 23 are strip-shaped. The N-type pillar 23 provides a conduction path when the super-junction device is turned on, and the P-type pillar 22 and the N-type pillar 23 deplete each other and bear the reverse bias together when the super-junction device is reverse-bias...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com