Planting module carrier

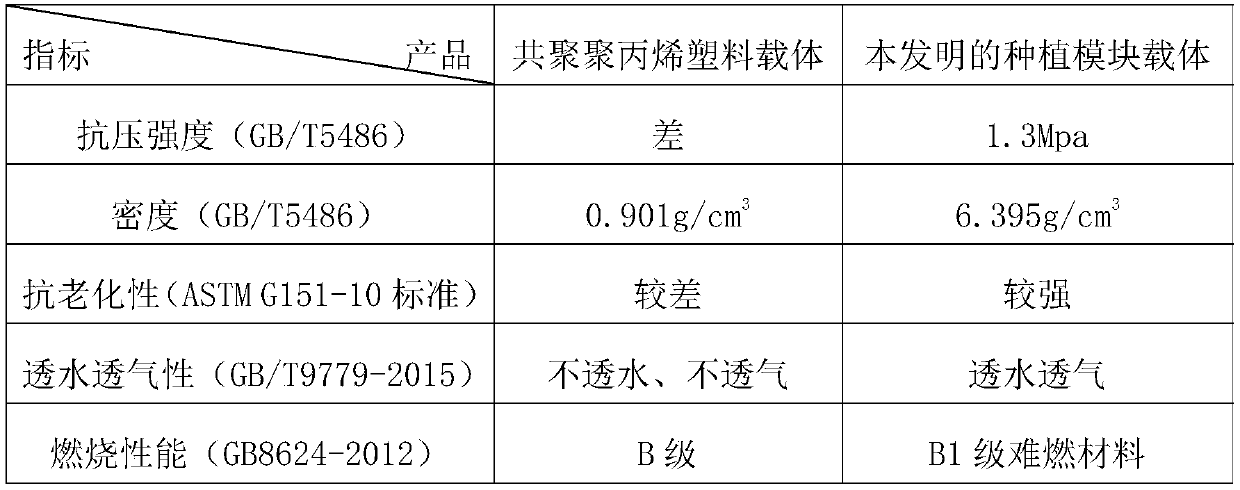

A planting module and carrier technology, which is applied in the field of planting module carriers, can solve the problems of brittleness, discoloration, short service life of the planting module carrier, and brittleness, etc., and achieve the advantages of good growth, good water absorption and water retention, and long durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take 100 parts of cement, 1.5 parts of dispersible latex powder and 0.5 part of methyl cellulose ether, mix, stir evenly, pour it into a mixer container with 100 parts of water, stir evenly until it becomes a paste, and then add rice husks 35 parts and 25 parts of perlite, stir until it becomes a gel; then pour it into the prepared mold, extrude it by pressing and vibrating, and maintain it for 26 days to obtain a planting module carrier.

Embodiment 2

[0024] Take 100 parts of cement, 2 parts of dispersible latex powder and 0.6 part of methyl cellulose ether, mix, stir evenly, pour it into a mixer container with 120 parts of water, stir until it becomes a paste, and then add rice husks 40 parts and 30 parts of perlite, stir until it becomes gel-like; then pour it into the prepared mold, extrude it by pressing and vibrating, and maintain it for 30 days to obtain the planting module carrier.

Embodiment 3

[0026] Take 100 parts of cement, 1.8 parts of dispersible latex powder and 0.5 part of methyl cellulose ether, mix, stir evenly, pour it into a mixer container with 110 parts of water, stir until it becomes a paste, and then add rice husks 38 parts and 28 parts of perlite, stir until it becomes a gel; then pour it into the prepared mold, extrude it by pressing and vibrating, and maintain it for 28 days to obtain the planting module carrier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com