Method for preparing cadmium chloride post-treatment manganese-doped cesium-lead-chlorine nanocrystalline and cadmium chloride post-treatment manganese-doped cesium-lead-chlorine nanocrystalline

A technology of nanocrystals and cadmium chloride, applied in chemical instruments and methods, nanotechnology, nano-optics, etc., can solve problems such as luminous efficiency lower than 100%, achieve passivation of surface defects and deep defect energy levels, and enhance luminescence The effect of quantum efficiency and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

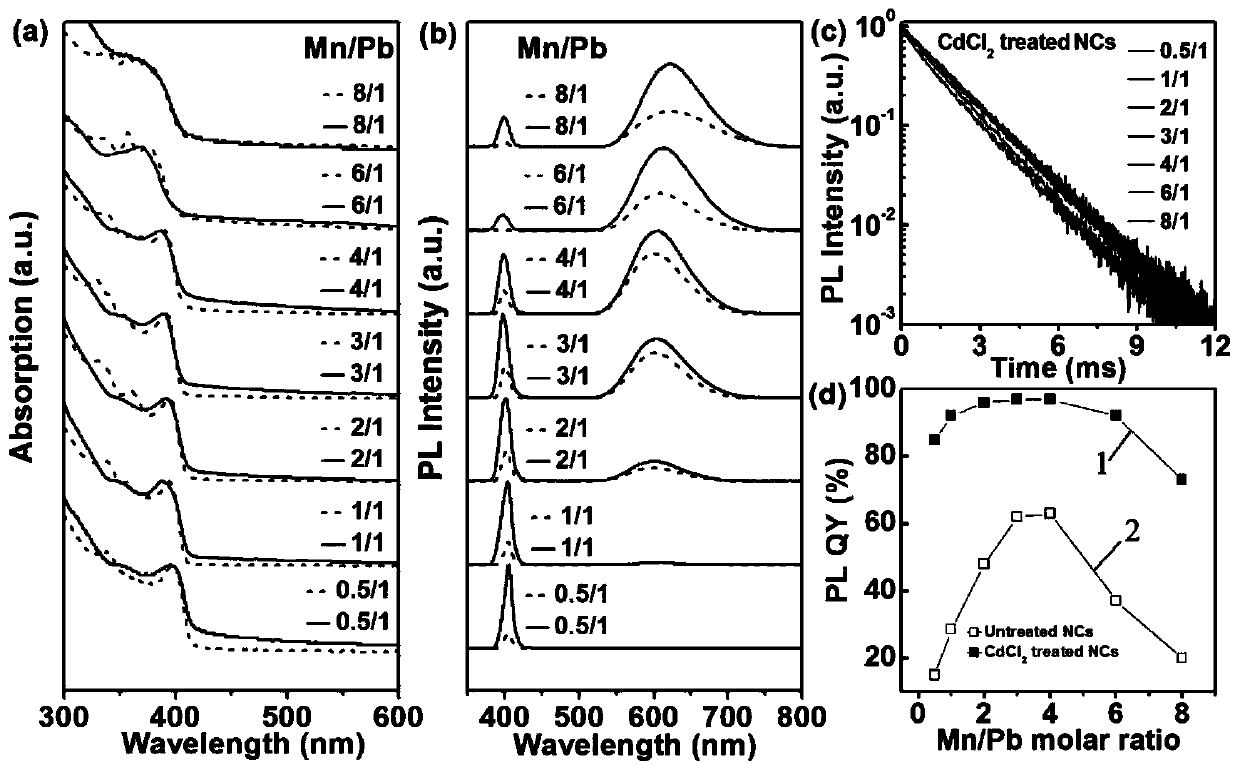

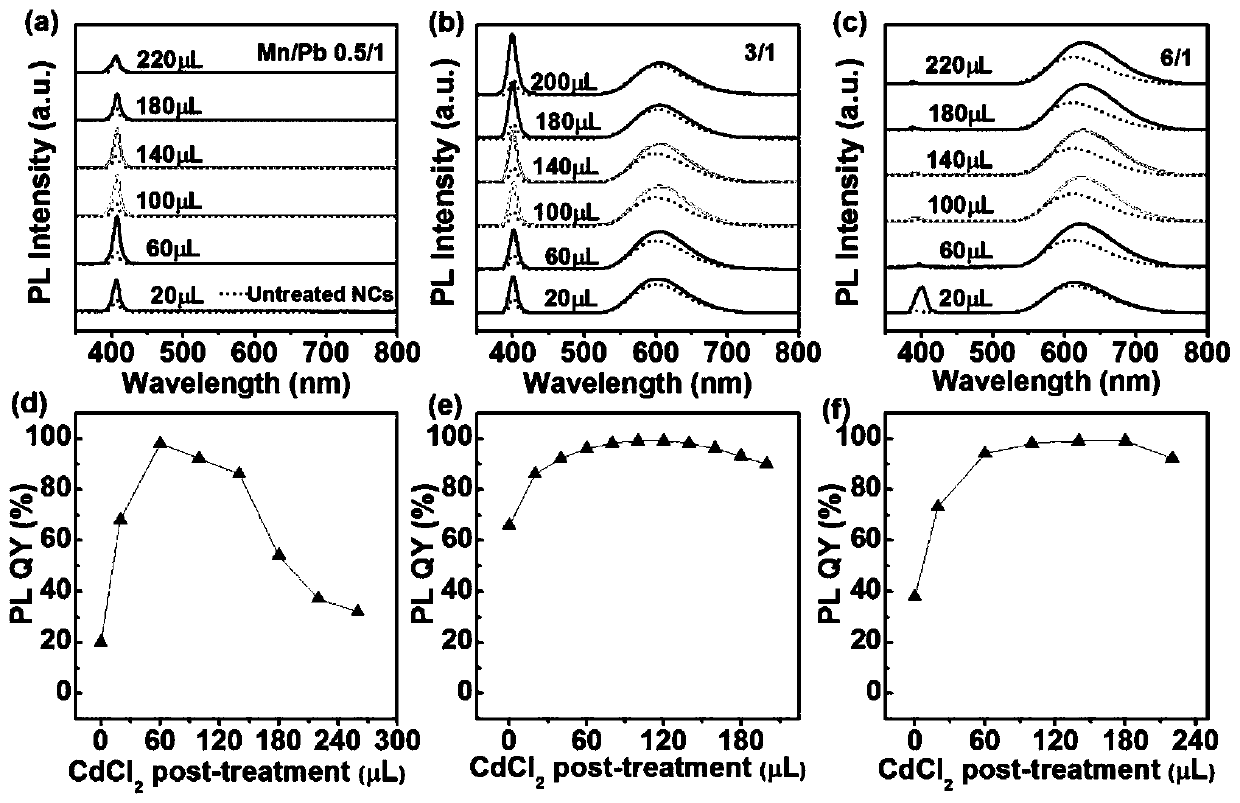

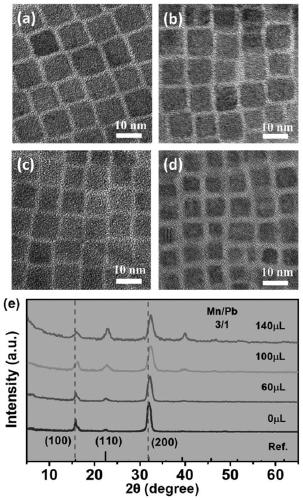

Method used

Image

Examples

Embodiment 1

[0042] Step 1: Add 0.8mmol of cesium carbonate, 1mL of oleic acid, and 7mL of 1-octadecene into a 50mL No. 1 three-neck flask, heat to 110°C under vacuum conditions and keep for 20 minutes to remove gas until bubbles appear in the reactant disappeared, and argon gas was introduced, and under the protection of argon gas, the mixed solution was stirred and heated to 150° C., and kept at this temperature until the solution was clear and transparent to obtain a cesium oleate precursor solution.

[0043] Step 2: Add 0.2mmol manganese chloride, 0.4mmol lead chloride, 1.5mL oleic acid, 1.5mL oleylamine, 1mL tri-n-octylphosphine, and 6mL 1-octadecene to a 50ml No. 2 three-necked flask and mix , the reaction mixture was heated to 110° C. under vacuum conditions, and kept for 30 minutes until the mixture was clear and transparent, and argon gas was introduced to raise the temperature of the reaction solution to 190° C.

[0044] Step 3: Inject 0.25 mL of the cesium oleate precursor solut...

Embodiment 2

[0047] Step 1: Add 0.8mmol of cesium carbonate, 1mL of oleic acid, and 7mL of 1-octadecene into a 50mL No. 1 three-neck flask, heat to 110°C under vacuum conditions and keep for 20 minutes to remove gas until bubbles appear in the reactant disappeared, and argon gas was introduced, and under the protection of argon gas, the mixed solution was stirred and heated to 150° C., and kept at this temperature until the solution was clear and transparent to obtain a cesium oleate precursor solution.

[0048] Step 2: Add 0.2mmol manganese chloride, 0.4mmol lead chloride, 1.5mL oleic acid, 1.5mL oleylamine, 1mL tri-n-octylphosphine, and 6mL 1-octadecene to a 50ml No. 2 three-necked flask and mix , the reaction mixture was heated to 110° C. under vacuum conditions, and kept for 30 minutes until the mixture was clear and transparent, and argon gas was introduced to raise the temperature of the reaction solution to 190° C.

[0049] Step 3: Inject 0.25 mL of the cesium oleate precursor solut...

Embodiment 3

[0054] The reaction conditions and steps are the same as in Example 1, except that the manganese chloride in step 2 is 0.3 mmol, and the lead chloride is 0.3 mmol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com