Detection method for directly determining trace halogen

A detection method and micro-quantity technology, applied in the detection system field, can solve problems such as low sample volume, harsh test solution requirements, and low atomization efficiency, and achieve the effect of improving measurement sensitivity, improving analysis sensitivity, and broad application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

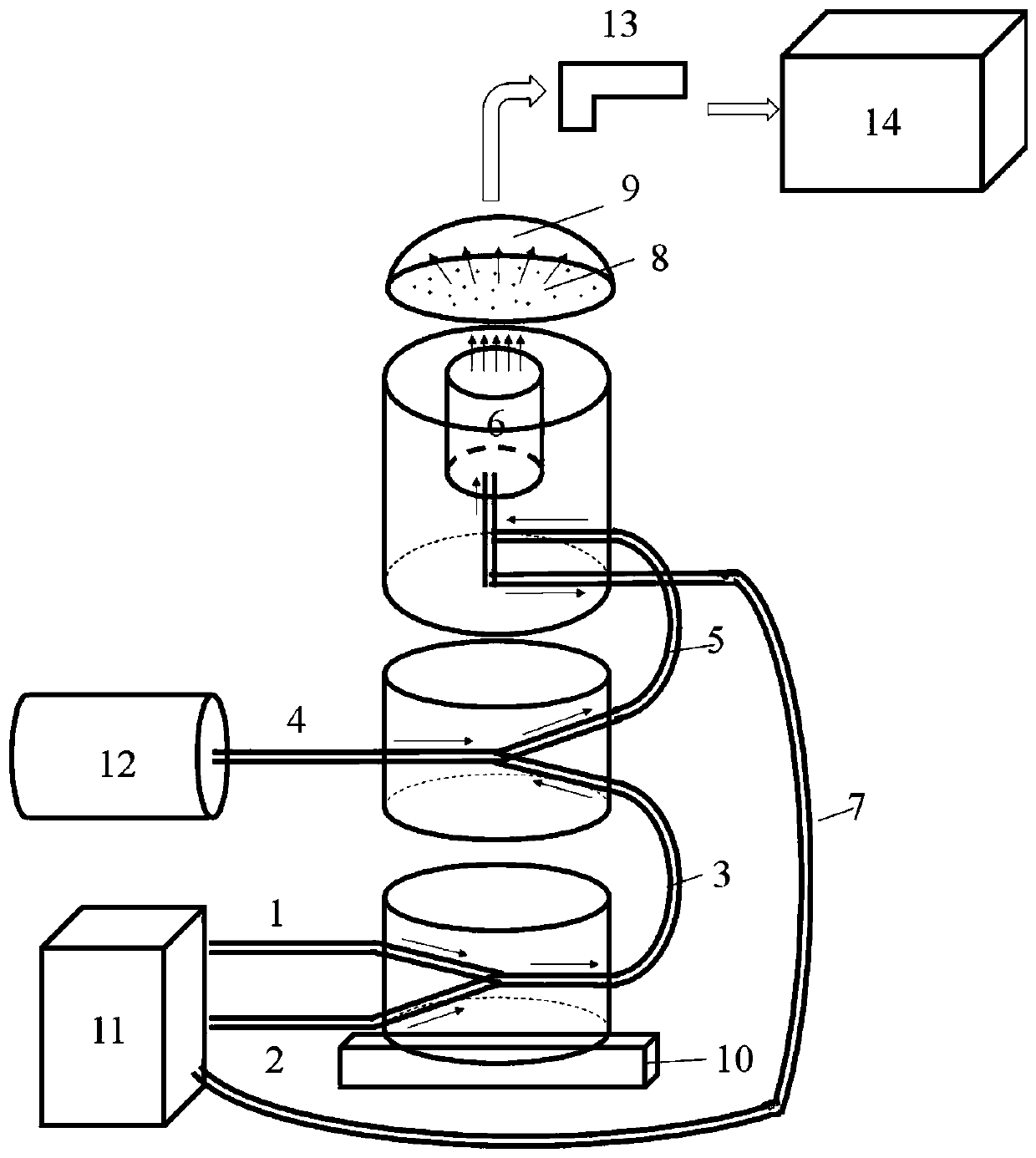

[0078] This example is based on figure 1 The detection system shown uses the aforementioned detection method provided in this manual to detect bromine and iodine in the sample. The detection device wherein adopts the ICP-OES of Platinum Elmer Company, and the working condition of this detection device is as comparative example 1, and the oxidizing agent in the reaction reagent that the present embodiment adopts is 20mM KMnO 4 Solution, and the kind and concentration of acid used can refer to Table 2, and, in the adopted standard sample, bromine concentration is 10mg / L, and iodine concentration is 1mg / L. As can be seen from Table 2, the test results show that compared with the direct determination of bromine and iodine by the conventional sampling system, the emission intensity of bromine and iodine in this embodiment has been significantly improved, that is, its determination sensitivity has been significantly improved.

[0079] Table 2 to the determination result of bromine ...

Embodiment 2

[0082] This embodiment is basically the same as Embodiment 1. The difference is that the concentration of nitric acid in the reaction reagent used is 4M, and the concentration of the oxidizing agent used can refer to Table 3. And, the bromine concentration in the standard sample adopted is all 1mg / L, and the iodine concentration is all 0.5mg / L. It can be seen from Table 3 that the oxidant KMnO 4 When the concentration is 1-50mM. Referring to Table 3, the test results show that compared with the direct measurement method using a conventional sampling system, the determination sensitivity of bromine and iodine in this embodiment is significantly improved.

[0083] Table 3 is the impact result of the concentration of oxidant on assay effect

[0084]

[0085]

Embodiment 3

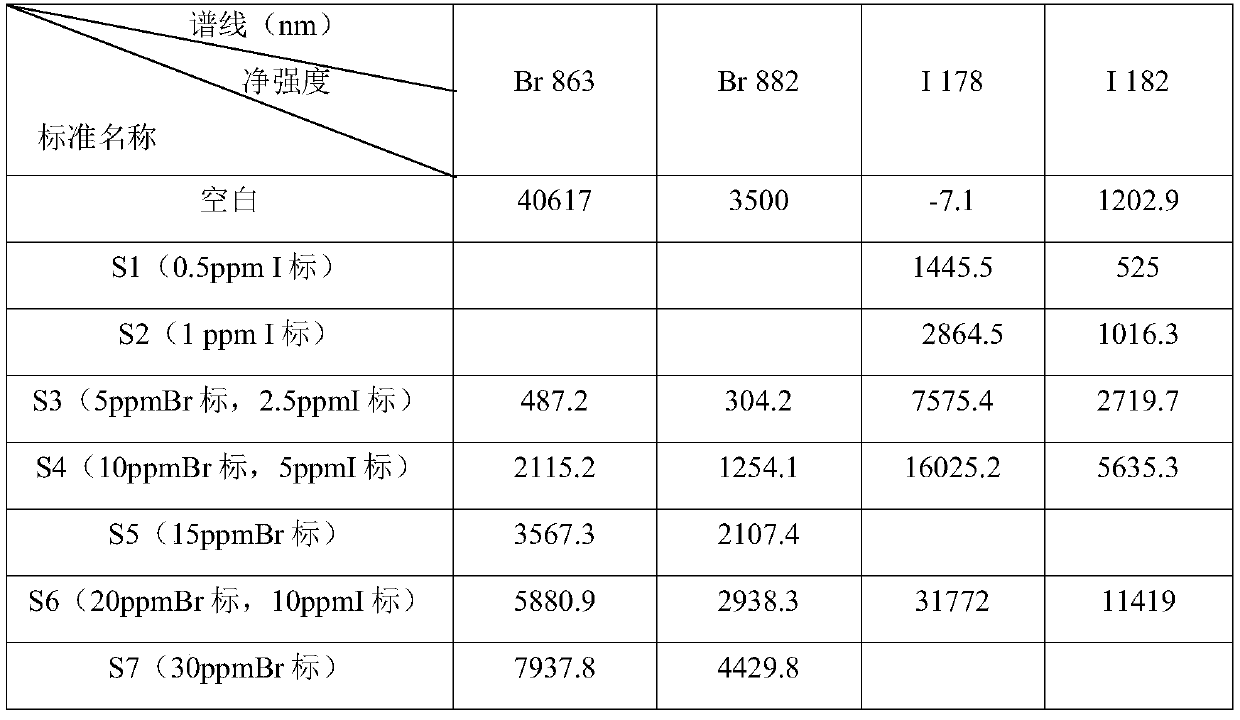

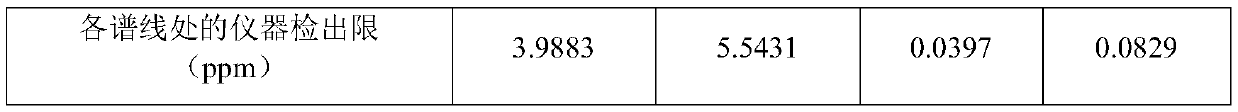

[0087] This embodiment is basically the same as Example 1, the difference is that the reaction reagent used in this embodiment is KMnO with a concentration of 2mM 4 solution and a concentration of 4M HNO 3 , Table 4 is the measurement result of bromine and iodine using the present embodiment. It can be seen from Table 4 that the linearity of the bromine and iodine standard solution series at each analysis line is good (R>0.999), which meets the requirements of the ICP-OES quantitative test. In addition, from Table 1 and Table 4, it can be calculated that the sensitivity of the analytical method of the present invention to measure bromine and iodine has improved at least 20 times, and the detection limit of the detection device also obviously reduces (wherein the detection limit of bromine has reduced 26 times, and the detection limit of iodine The limit of detection was reduced by a factor of 14).

[0088] The determination result of table 4 bromine and iodine

[0089]

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com