Catalyst capable of simultaneously removing COS and H2S in garbage gasification, and preparation method thereof

A catalyst and removal technology, applied in chemical instruments and methods, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of easy loss of active components, deactivation of active components, easy blockage of catalyst channels, etc., to achieve desulfurization Best efficiency, simple method, low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

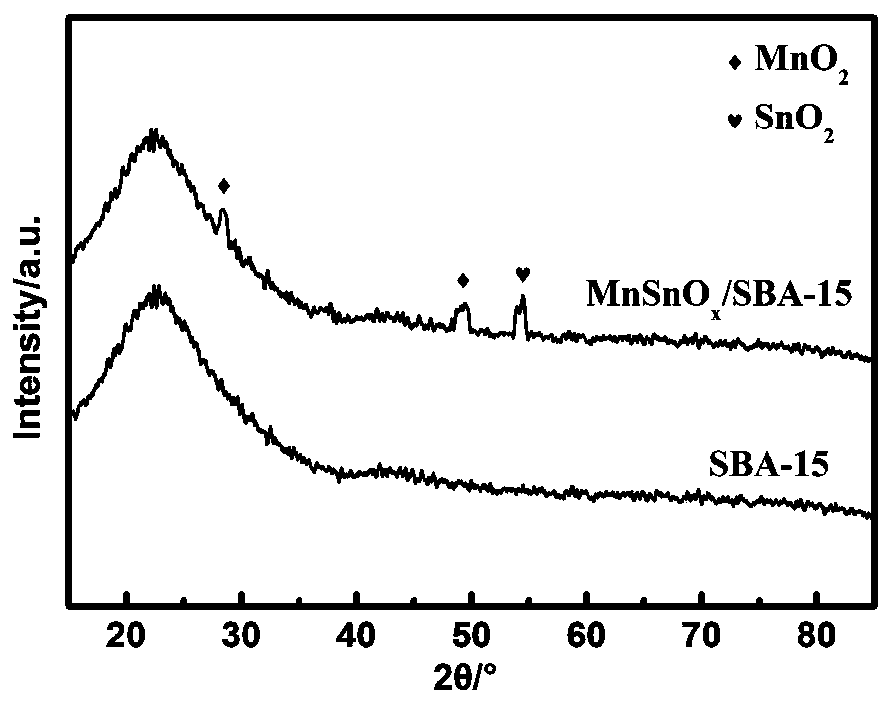

[0045] The first step is to pretreat the unreleased SBA-15 molecular sieve: first dissolve the SBA-15 molecular sieve in ethanol and reflux, wash and dry it twice, then dissolve it in n-hexane and ultrasonically disperse it, and drop by drop Add chloromethyltrimethylsilane, and continue ultrasonication for 20-40 minutes; finally, transfer the treated SBA-15 molecular sieve into a water bath for reflux for 10-13 hours, filter, wash and dry, and prepare for subsequent experiments.

[0046] The second step, the active component material is carried out pretreatment: weigh 2.5g 50%Mn(NO 3 ) 2 Solution, configure 50mL solution in a beaker; weigh 1.02g SnCl 4 ·5H 2 O, configure 50mL solution in a beaker; mix the two solutions thoroughly, which means MnSn solution;

[0047] Step 3: Weigh 5g of the treated SBA-15 molecular sieve, add it into the beaker of the MnSn solution, and mix well;

[0048] The fourth step, put the mixed solution in a magnetic stirrer, stir at a constant spee...

Embodiment 2

[0052] The difference from Example 1 is:

[0053] In the second step, the mixed solution is FeSn solution (the step of preparing FeSn solution refers to the prior art).

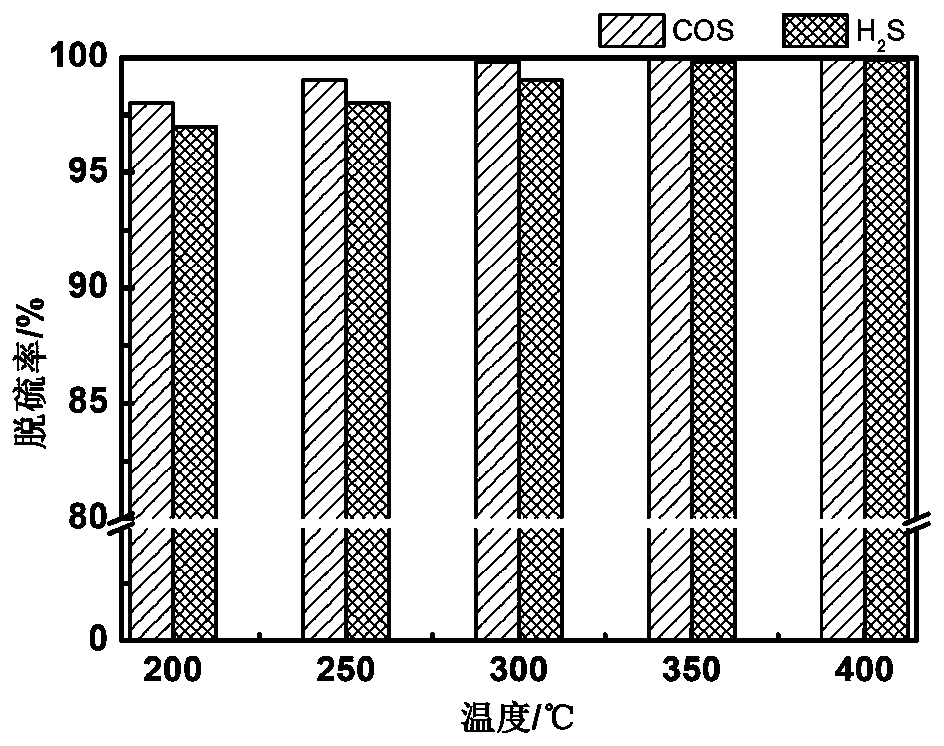

[0054] The COS content of simulated garbage gasification gas is 0.2%, H 2 S content 2.4%, the rest is H 2 O and N 2 Used as balance gas for desulfurization experiments. During the experiment, the COS flow rate was 0.2mL / min, and the H 2 S flow rate 2.4mL / min, carrier gas H 2 O and N 2 The flow rate is 97.4mL / min for desulfurization experiments. The experimental results show that the desulfurization efficiency is 94% at 350°C.

Embodiment 3

[0056] The difference from Example 1 is:

[0057] In the second step, the mixed solution is a ZnSn solution (the step of preparing the ZnSn solution refers to the prior art).

[0058] The COS content of simulated garbage gasification gas is 0.2%, H 2 S content 2.4%, the rest is H 2 O and N 2 Used as balance gas for desulfurization experiments. During the experiment, the COS flow rate was 0.2mL / min, and the H 2 S flow rate 2.4mL / min, carrier gas H 2 O and N 2 The flow rate is 97.4mL / min for desulfurization experiments. The experimental results show that the desulfurization efficiency is 89% at 350°C.

[0059] From above-mentioned embodiment 1-embodiment 3 as can be known, the present invention selects simulated waste gasification gas COS content 0.2%, H 2 S content 2.4%, the rest is H 2 O and N 2 When used as balance gas for desulfurization experiments, at 350°C, MnSnO x / SBA-15 catalyst has the best efficiency.

[0060] The choice of carrier also affects the desulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com