A kind of preparation method of ag nanoparticles

A nanoparticle and plasma technology, applied in the direction of nanotechnology, can solve the problems of environmental pollution, high production cost, and complicated preparation process of Ag nanoparticles, and achieve the effects of low dosage, convenient operation, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

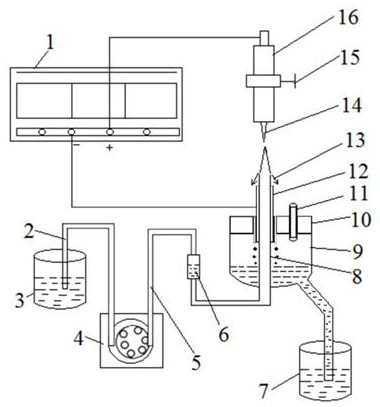

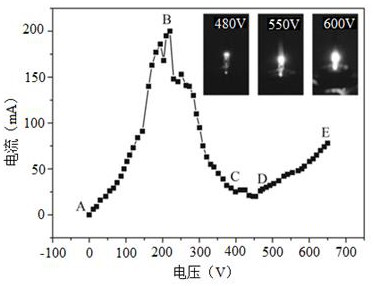

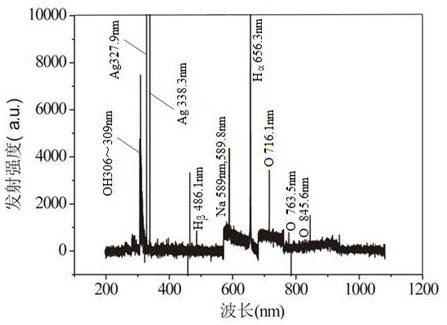

[0037] use figure 1 The liquid cathode glow discharge plasma generator shown. Adjust the three-dimensional moving platform 15 so that the distance between the lower end of the platinum needle electrode 14 and the top of the capillary 8 is 1 mm; inject the silver nitrate solution with pH=1 and molar volume concentration of 0.05 mol / L into the solution pool 3, and start the peristaltic pump 4. Make the silver nitrate solution in the solution tank 3 enter the capillary 8 at a constant speed at a flow rate of 1 mL / min, overflow from the top of the capillary 8, and contact the lower end of the platinum needle electrode 14; turn on the DC voltage-stabilized power supply 1 to control the yin and yang The voltage between the electrodes is 480V and the current is 28mA; the DC voltage-stabilized power supply 1, the platinum needle electrode 14 and the graphite tube 12 form a closed loop; during the electrification process, the solution overflowing from the top of the capillary 8 is elec...

Embodiment 2

[0039] Pick figure 1 The liquid cathode glow discharge plasma generator shown. Adjust the three-dimensional moving platform 15 so that the distance between the lower end of the platinum needle electrode 14 and the top of the capillary 8 is 2 mm; inject the silver nitrate solution with pH=1 and molar volume concentration of 0.10 mol / L into the solution pool 3, and start the peristaltic pump 4. Make the silver nitrate solution in the solution pool 3 enter the capillary 8 at a constant speed with a flow rate of 3.5 mL / min, overflow from the top of the capillary 8, and contact the lower end of the platinum needle electrode 14; turn on the DC voltage-stabilized and constant-current power supply 1, and control the The voltage between the cathode and anode is 550V, and the current is 32mA; the DC voltage-stabilized power supply 1, the platinum needle electrode 14 and the graphite tube 12 form a closed loop; during the electrification process, the solution overflowing from the top of ...

Embodiment 3

[0041] Pick figure 1 The liquid cathode glow discharge plasma device shown. Adjust the three-dimensional moving platform 15 so that the distance between the lower end of the platinum needle electrode 14 and the top of the capillary 8 is 3 mm; inject the silver nitrate solution with pH=1 and molar volume concentration of 0.15 mol / L into the solution pool 3, and start the peristaltic pump 4. Make the silver nitrate solution in the solution tank 3 enter the capillary 8 at a constant speed with a flow rate of 6 mL / min, overflow from the top of the capillary 8, and contact the lower end of the platinum needle electrode 14; turn on the DC voltage-stabilized power supply 1 to control the yin and yang The voltage between the electrodes is 600V and the current is 58mA; the DC voltage-stabilized power supply 1, the platinum needle electrode 14 and the graphite tube 12 form a closed loop; during the electrification process, the solution overflowing from the top of the capillary 8 is elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com