Machining method of rubber composite gasket provided with metallic framework and forming mould

A metal skeleton and composite gasket technology, used in household appliances, other household appliances, household components, etc., can solve the problem of insufficient bonding strength between metal skeleton and EPDM rubber, and achieve improved stability and service life. Adhesive strength, the effect of improving the adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

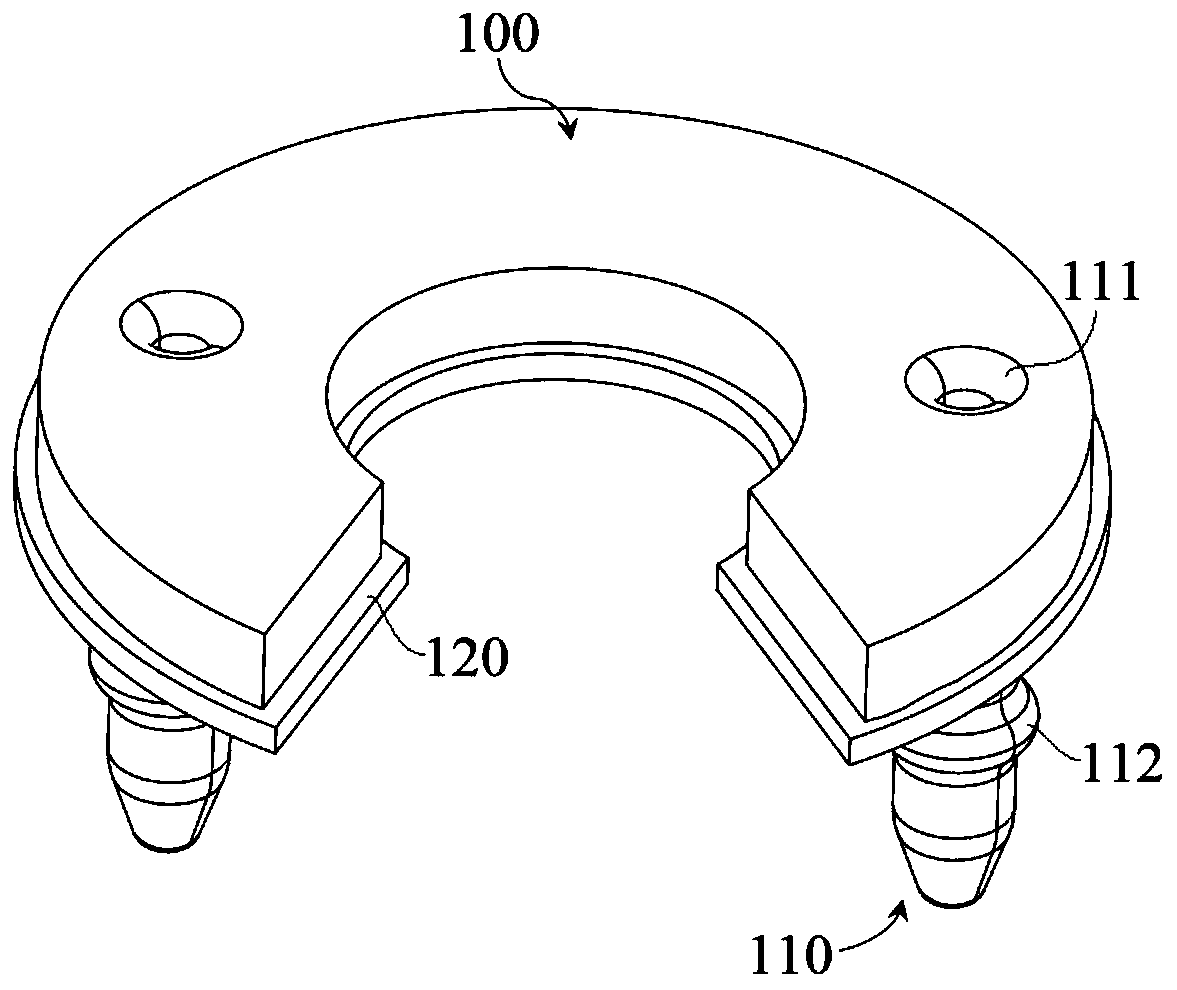

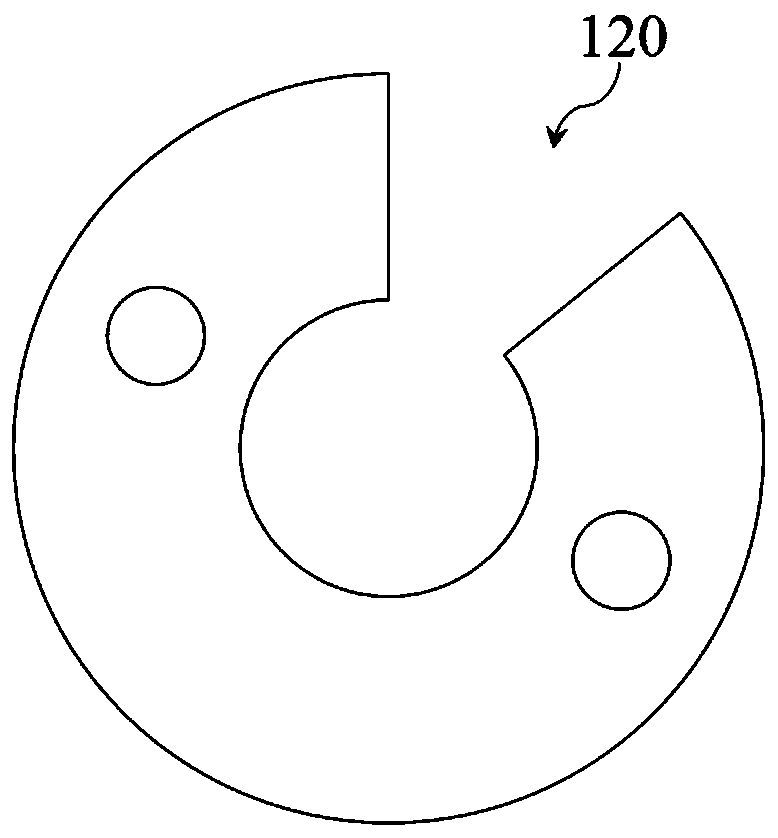

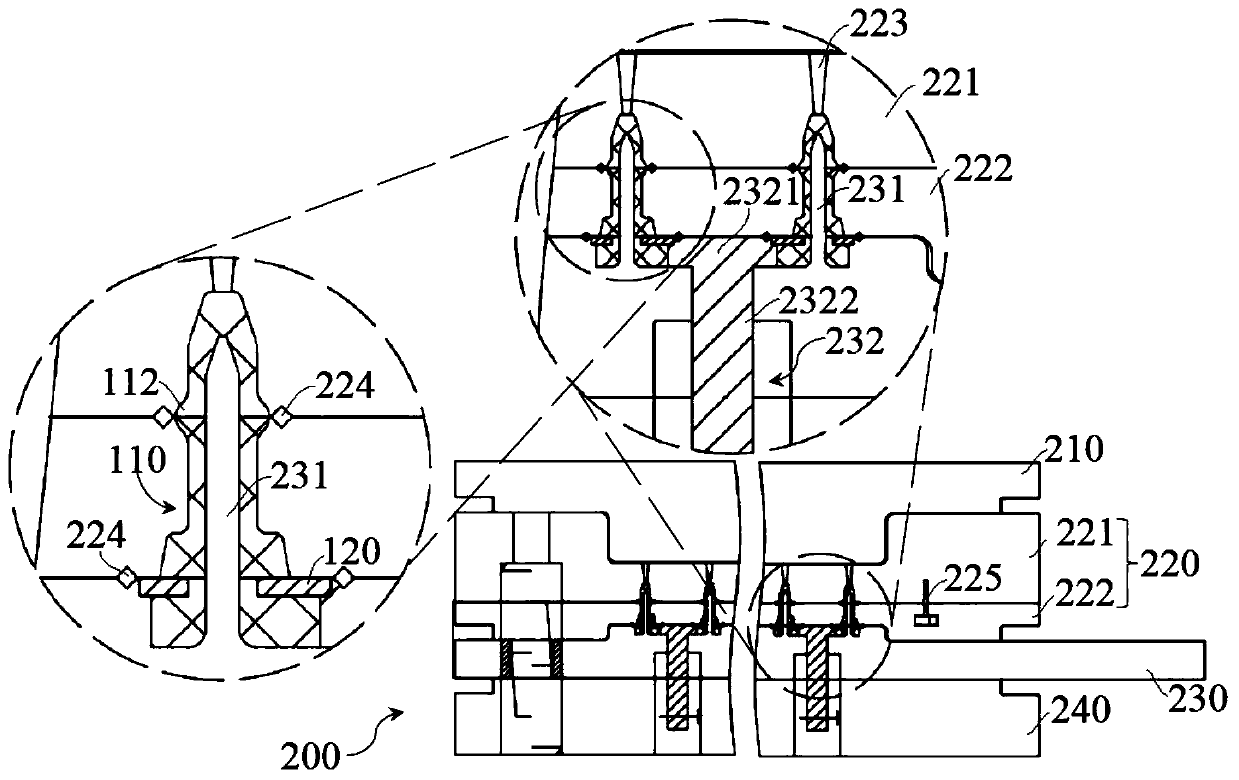

[0053] In this embodiment, the specific steps for processing the composite gasket 100 using the aforementioned molding die 200 are as follows:

[0054] Step 1. Preparation of metal skeleton and rubber

[0055] S1. The metal material is: 45# steel, the raw material of the metal skeleton with a thickness of 1mm, the semi-finished product is prepared through the stamping process, and then the metal skeleton is obtained through vibrating and electroplating treatment, wherein the surface of the metal skeleton needs to be nickel-plated, and the nickel content is 12%, coating thickness is 8um.

[0056] S2. Clean the metal frame with gasoline and dry it. Use spraying method to coat CH205 adhesive on the surface of the metal frame and dry it at 23°C for 0.75 hours. Then apply RC202 adhesive on the coating of CH205 adhesive. C to dry for 0.75 hours.

[0057] S3. According to the size of the forming mold 200 ; use a rubber cutting machine to cut the rubber material of the composite gas...

Embodiment 2

[0064] In this embodiment, the thickness of the metal skeleton in step S1 is 1.3mm, the nickel content is 16%, and the coating thickness is 20um.

[0065] In step S2, the surface of the metal skeleton is coated with CH205 adhesive, and dried at 20° C. for 0.5 hours, and then coated with 233X adhesive on the coating of CH205 adhesive, and dried at 20° C. for 0.5 hours.

[0066] In step S3, the rubber material is specifically composed of the following components by mass fraction: 55 parts of EPDM raw rubber, 2.5 parts of zinc oxide, 0.1 part of stearic acid, 10 parts of fast extruded carbon black, 4 parts of semi-reinforcing carbon black 1 part, 3 parts of precipitated silica, 5 parts of calcined clay, 1 part of active agent, 0.05 part of silane coupling agent, 0.1 part of comaron, 1 part of anti-aging agent, 1 part of accelerator, 2 parts of vulcanizing agent.

[0067] In step 3, the vulcanization temperature of the vulcanizer is controlled to be 170°C, the vulcanization time i...

Embodiment 3

[0069] In this embodiment, the thickness of the metal skeleton in step S1 is 1.5mm, the nickel content is 18%, and the coating thickness is 25um.

[0070] In step S2, the surface of the metal skeleton is coated with CH205 adhesive, and dried at 30°C for 1 hour, and then coated with RC202 adhesive on the coating of CH205 adhesive, and dried at 30°C for 1 hour.

[0071] In step S3, the rubber material is specifically composed of the following components by mass fraction: 60 parts of EPDM raw rubber, 3.5 parts of zinc oxide, 0.5 parts of stearic acid, 15 parts of fast extruded carbon black, 8 parts of semi-reinforcing carbon black 7 parts of precipitated silica, 7 parts of calcined clay, 3 parts of activator, 1.2 parts of silane coupling agent, 0.5 parts of comaron, 2 parts of anti-aging agent, 2 parts of accelerator, and 5 parts of vulcanizing agent.

[0072] In step 3, the vulcanization temperature of the vulcanizer is controlled to be 170°C, the vulcanization time is controlle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com