RGO/polyimide composite aerogel, preparation method and application thereof

A composite airgel and polyimide technology, applied in the field of multifunctional materials, can solve the problems of limited electrical conductivity, high heat dissipation capacity, etc., achieve low cost, improve load bearing and bending resistance, and realize large-scale and large batches The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

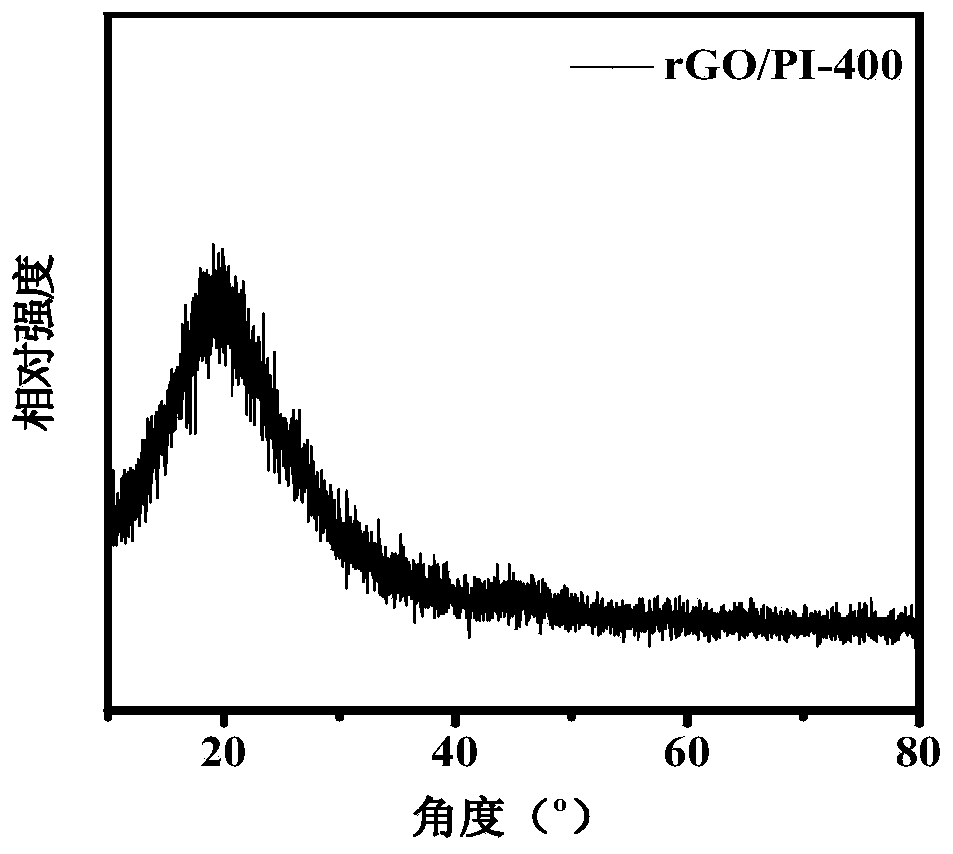

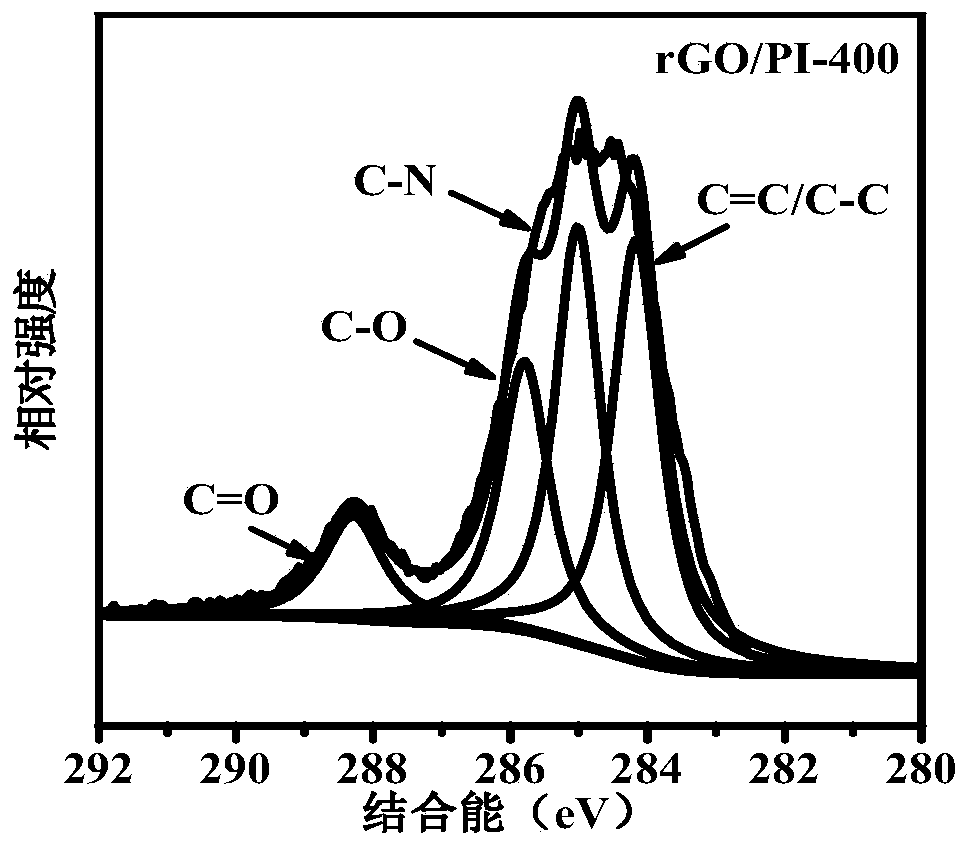

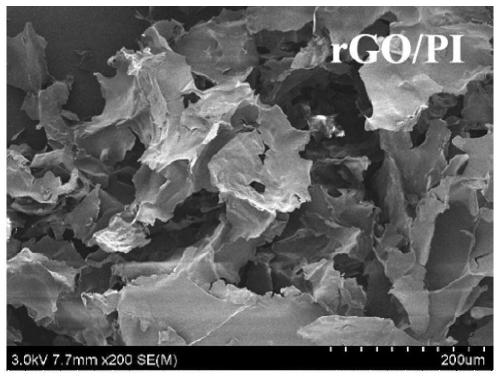

[0029] The lightweight rGO / polyimide composite multifunctional airgel of the present invention is prepared by the following method:

[0030] Step 1, preparation of polyamic acid: add 3.96g of 4,4'-diaminodiphenyl ether into 200mL of N,N-dimethylacetamide solution, stir well, then add 4.36g of pyromellitic tetra Formic acid dianhydride, continue to stir, then pour the reaction solution into excess deionized water, and finally filter, wash, and dry the resulting precipitate under vacuum at 60°C to obtain a dry product;

[0031] Step 2, preparation of rGO / polyimide precursor solution: Add 1 g of the dry product obtained in step 1 to 18.52 mL of deionized water containing 0.48 g of triethylamine, and stir magnetically for a period of time to obtain a polyimide precursor solution; add 5mL graphene oxide solution to the polyimide precursor solution, stir evenly, freeze-dry the mixed material for 24h, and record it as rGO / PI (rGO / polyimide composite airgel precursor);

[0032] In st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com