Method for converting polycarbonate compound-containing material into cyclic hydrocarbon in aviation kerosene

A polycarbonate and aviation kerosene technology, which is applied in the field of plastics, can solve the problems of wasting the recycling value of waste plastics and occupying resources, and achieves the effect of solving energy problems, solving environmental problems, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

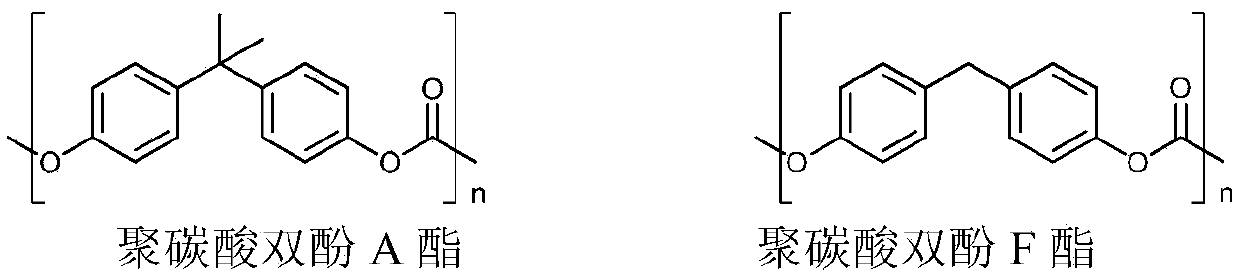

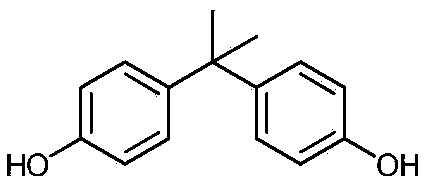

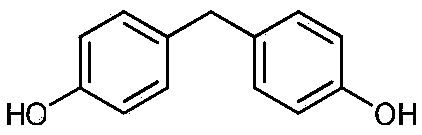

[0036] 1. Investigate the reactivity of polycarbonates under various reaction conditions during alcoholysis.

[0037] 1.1 The effect of reaction temperature on polycarbonate alcoholysis process. Reaction conditions: 1g polybisphenol A carbonate, 40g methanol, reaction time: 3.5h. see table 1

[0038] Table 1. Different reaction temperatures

[0039]

[0040] As can be seen from Table 1, as the reaction temperature increases, the conversion rate of bisphenol A polycarbonate gradually increases, and the yield of bisphenol A also gradually increases until reaching the highest at 180 degrees.

[0041] 1.2 The influence of reaction time in polycarbonate alcoholysis process. Reaction conditions: 1g polybisphenol A carbonate, 40g methanol, reaction temperature: 180°C. see table 2

[0042] Table 2. Different reaction times

[0043]

[0044]

[0045] As can be seen from Table 2, with the increase of the reaction time, the yield of bisphenol A gradually increased, but no ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com