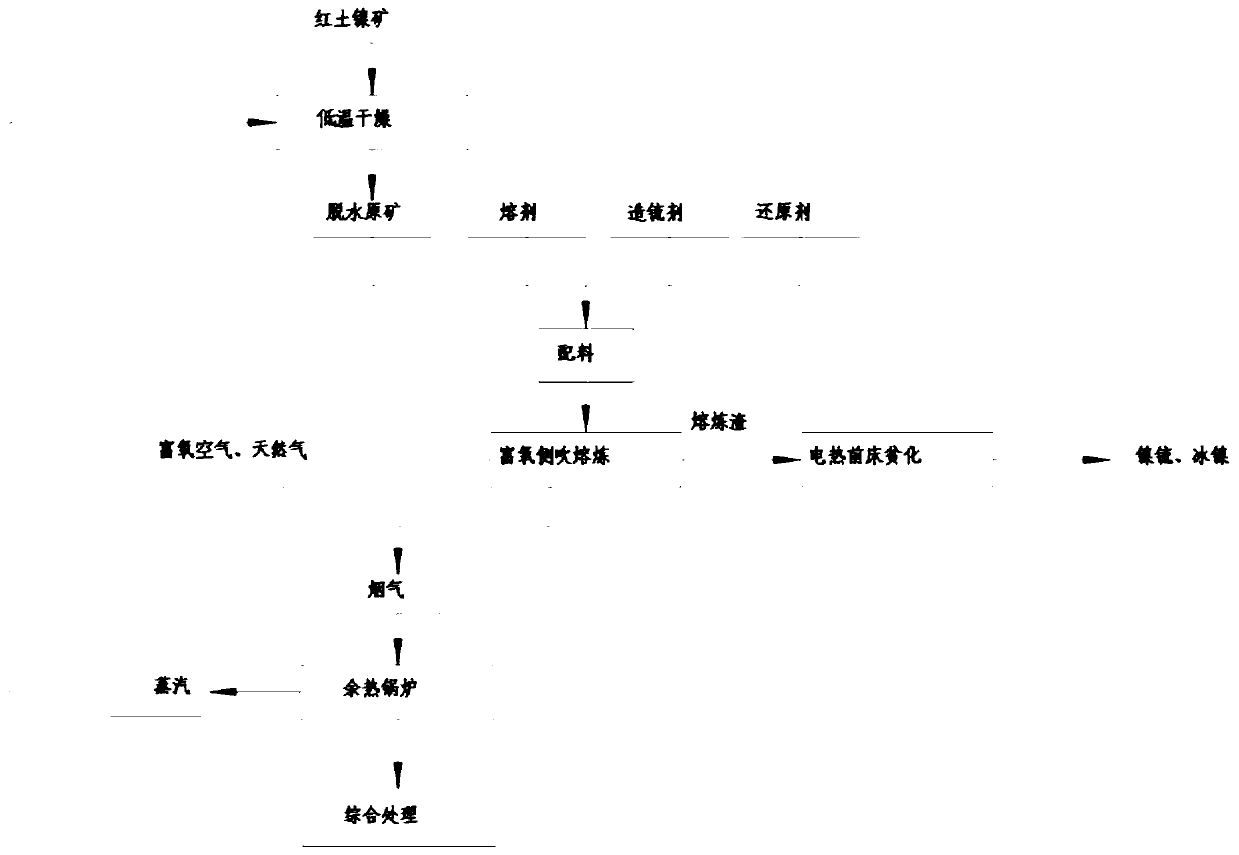

Smelting furnace for extracting valuable metal from laterite nickel ore and smelting method

A technology of laterite nickel ore and valuable metals, which is applied in furnaces, furnace materials, crucible furnaces, etc., can solve the problems of difficult and efficient utilization of low-grade laterite nickel ore, and achieve low smelting difficulty, fast smelting speed, and high nickel recovery rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

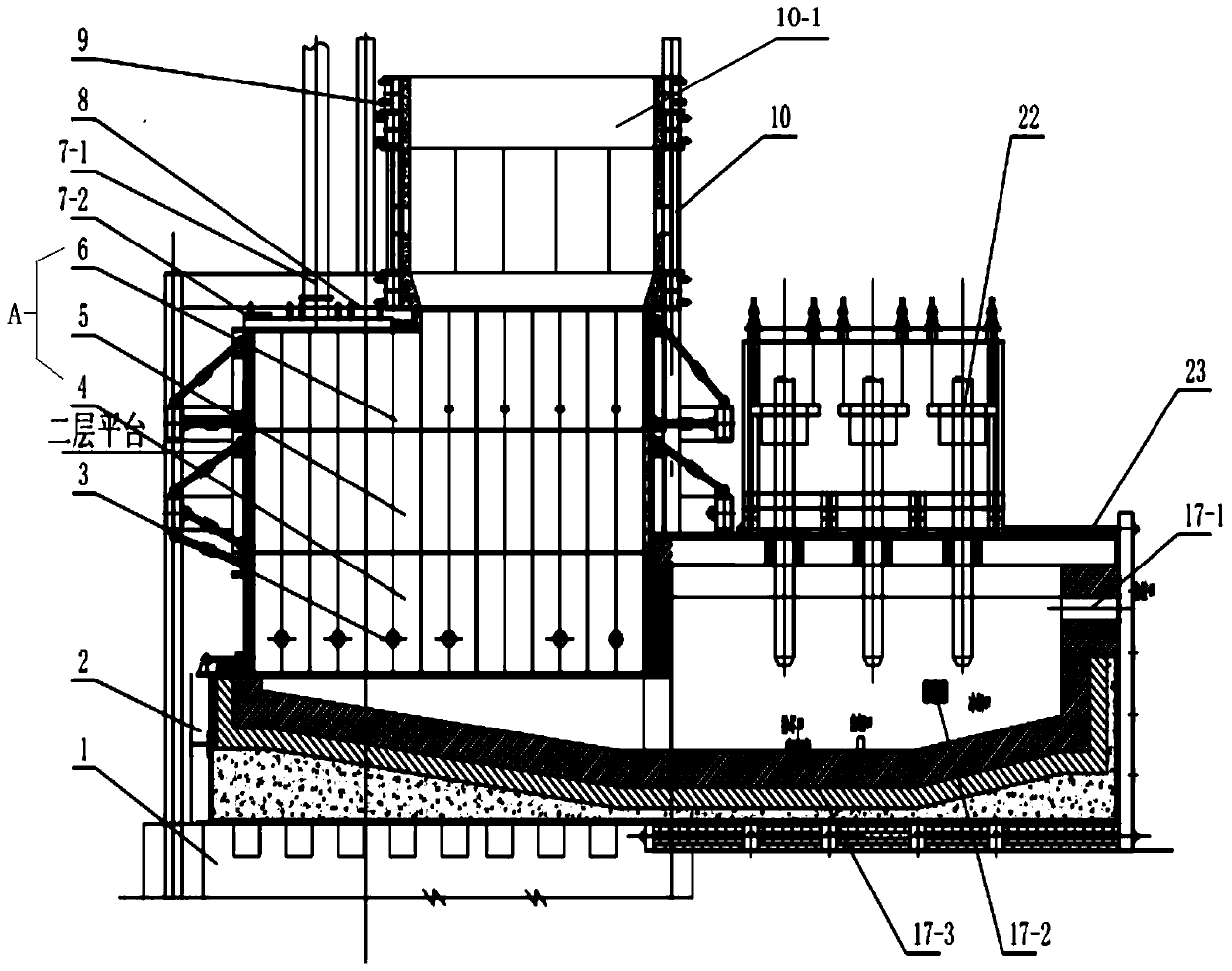

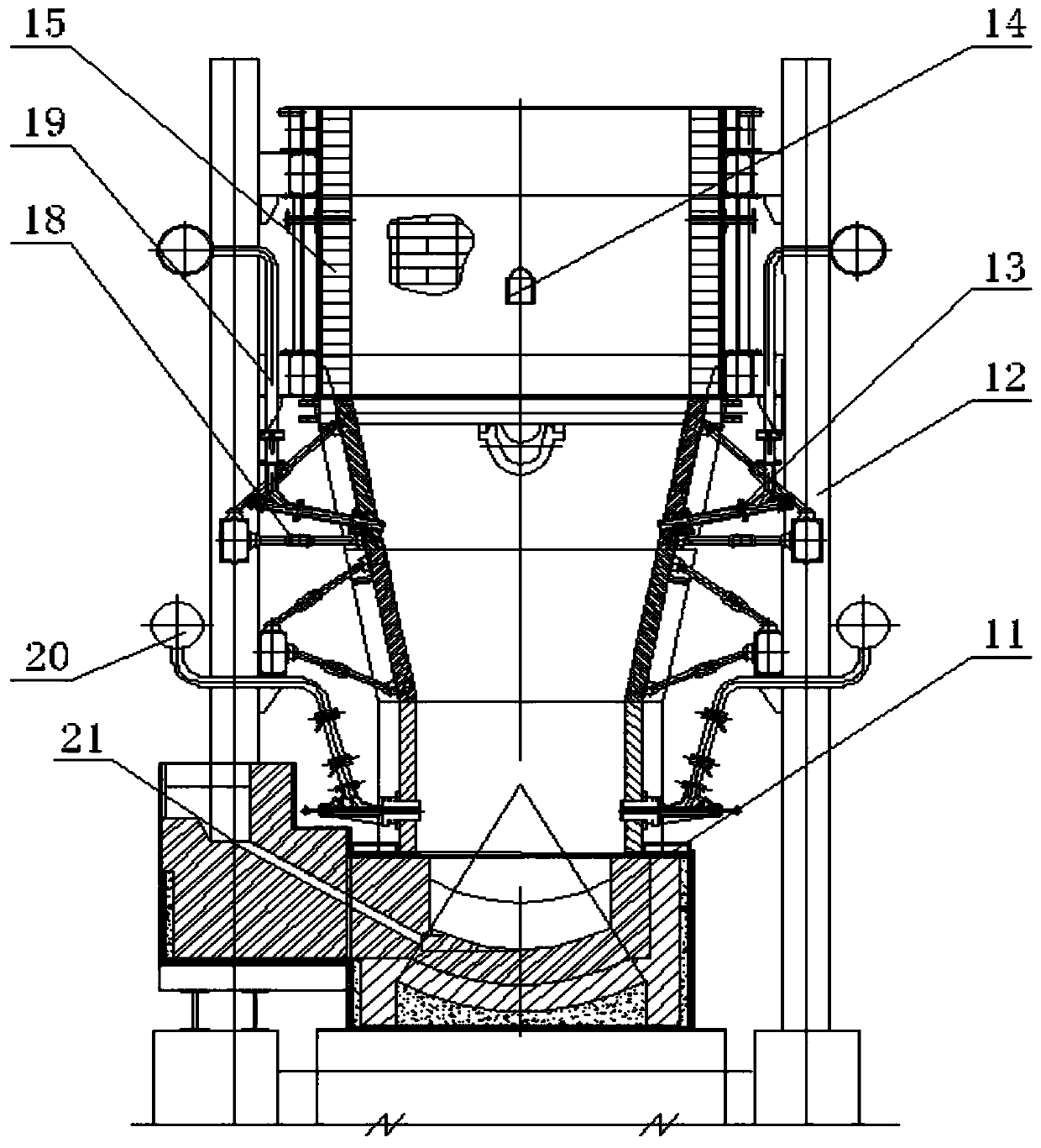

[0050] see figure 2 and image 3 , a smelting furnace for extracting valuable metals from laterite nickel ore, comprising a furnace body with a furnace chamber, the furnace body is divided into hearth section 2, furnace body section A and furnace top section 10- 1. The bottom side of the hearth section 2 is connected with an electric heating front bed 23, and the electric heating front bed 23 is provided with a slag discharge port 17-1 and a siphon port 17-2, and the inner end of the siphon port 17-2 is located The position is lower than the position of the inner end of the slag discharge port 17-1, the bottom area of the inner cavity of the electric heating front bed 23 is 1.3 of the bottom area of the inner cavity of the hearth section 2, and the electric heating front bed 23 is provided with electrodes 22 for heating ; The inner bottom surface of the hearth section 2 is inclined towards the direction where the electric heating front bed 23 is located, and the angle be...

Embodiment 2

[0064] Repeat Example 1, the difference is that in the present embodiment, Ni1.01wt% is contained in the laterite nickel ore, and the mass ratio of laterite nickel ore, reducing agent, matte-making agent, and flux is 100:8:18:10, wherein , the reducing agent is waste activated carbon, the flux is mixed with calcium carbonate and sodium carbonate at a mass ratio of 2:1, the melting temperature is 1300°C, and the oxygen concentration in the oxygen-enriched gas is 32vol%. The nickel grade in the obtained slag phase is 0.16wt%, and the nickel grade in the metal phase is 22.4wt%.

Embodiment 3

[0066] Repeat Example 1, the difference is that in the present embodiment, Ni1.34wt% is contained in the laterite nickel ore, and the mass ratio of laterite nickel ore, reducing agent, matte-making agent, and flux is 100:10:20:14, wherein , the reducing agent is coke, the flux is mixed with calcium carbonate and sodium carbonate at a mass ratio of 1:1, and the melting temperature is 1300°C. The nickel grade in the obtained slag phase is 0.12wt%, and the nickel grade in the metal phase is 19.5wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com