Sulfur response signal enhancement assembly of flame photometric detector and application thereof

A technology that responds to signals and flame luminosity. It is applied in the direction of photometry, instruments, and measuring devices using electric radiation detectors. It can solve problems such as the inability to guarantee the luminescence of sulfides, and achieve an increase in the area of the medium temperature zone, a simple mechanical structure, and improved The effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

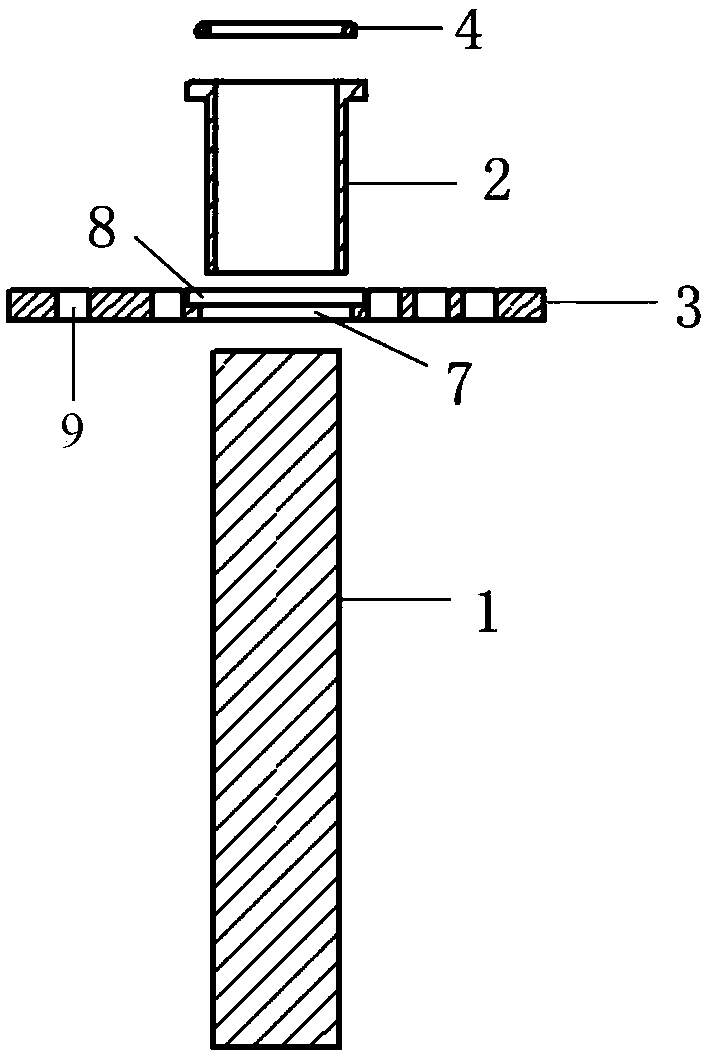

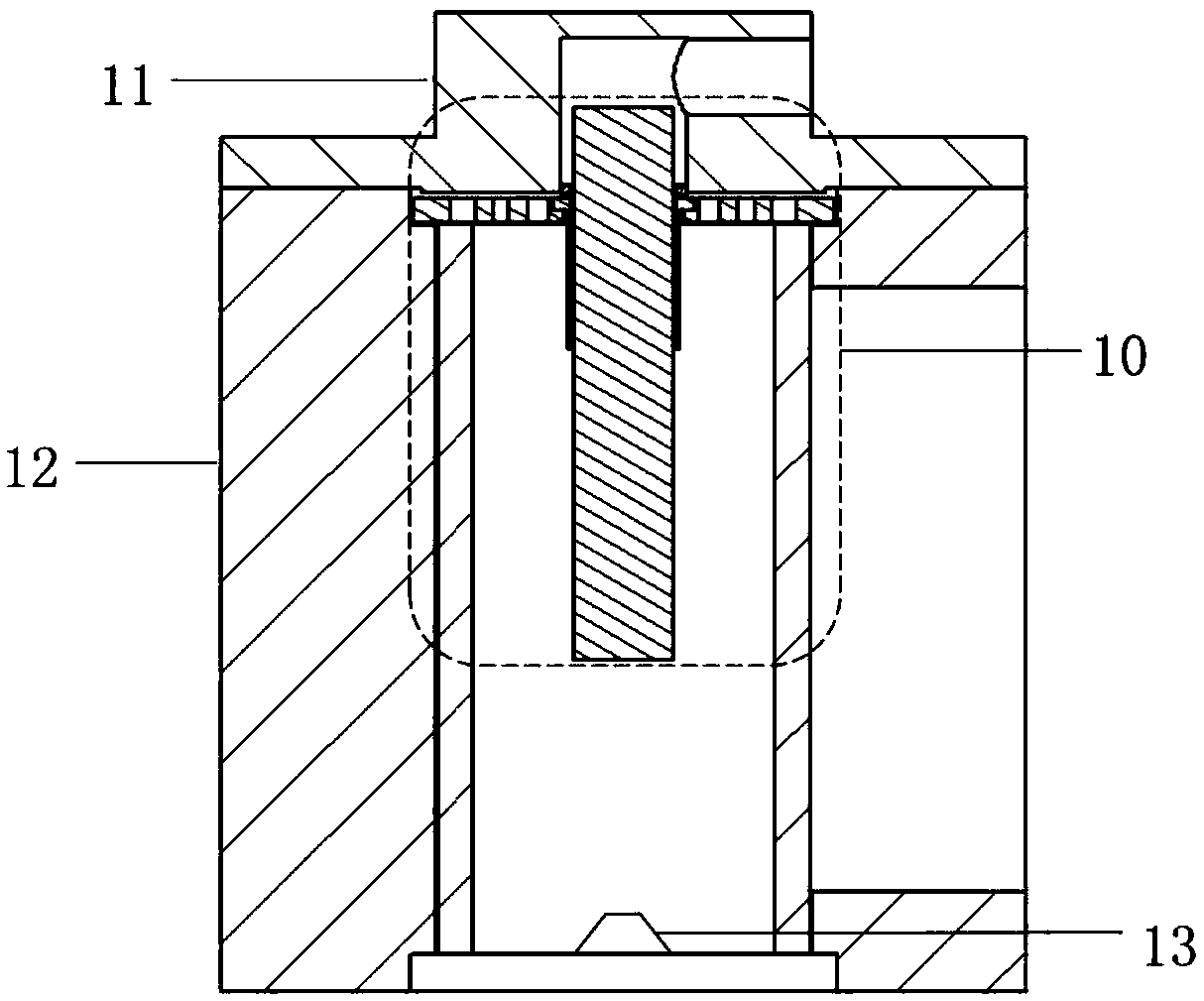

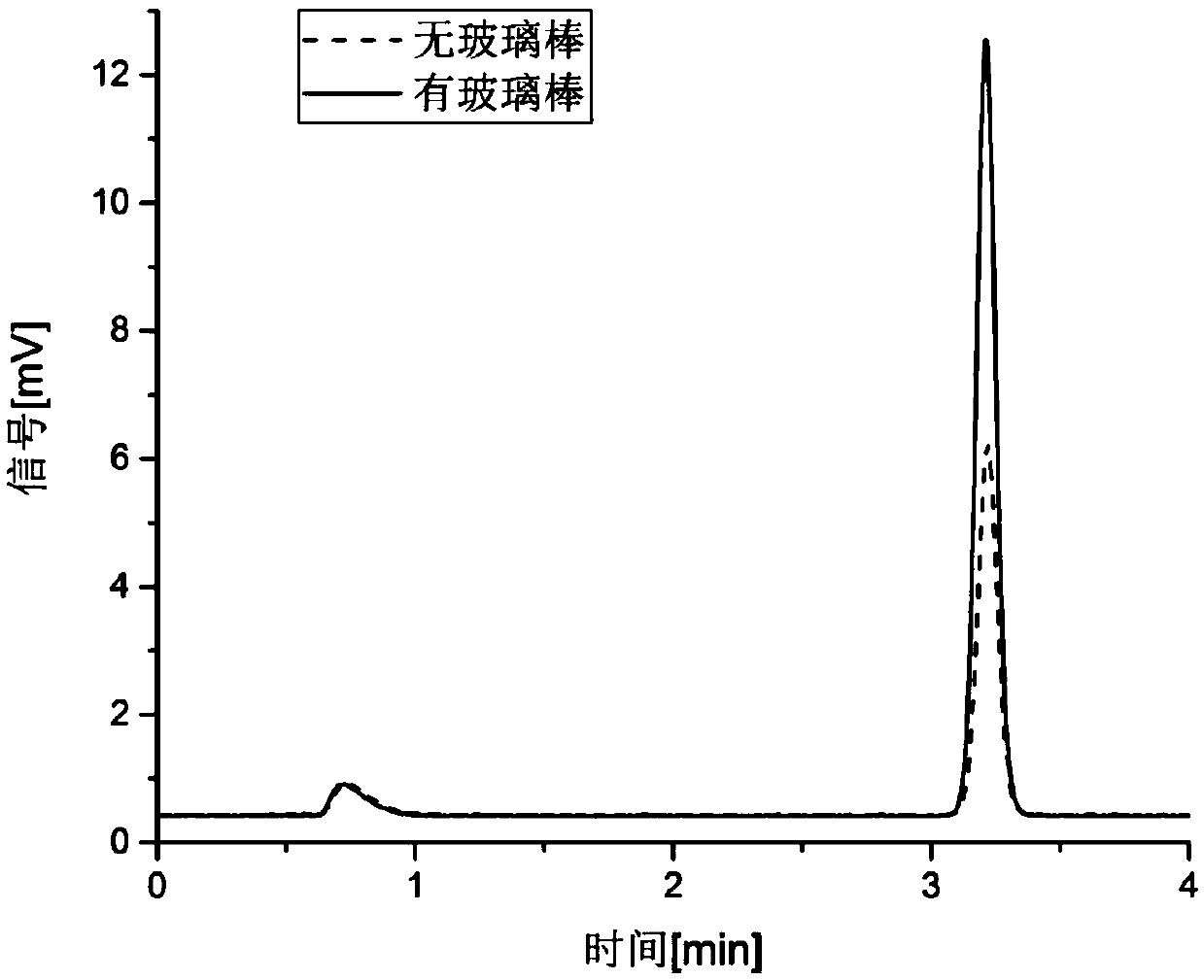

[0029] Sulfur-responsive signal enhancement components are used, and the cross-sectional schematic diagram is as follows figure 1 As shown, it consists of a quartz rod 1, a T-shaped cylinder 2, a circular porous baffle 3, and a metal ring 4. The T-shaped cylinder 2, the circular porous baffle plate 3 and the metal ring 4 are all stainless steel. The outer diameter of the quartz rod 1 is 4mm, and the length is 24mm, and the two end surfaces of the quartz rod are polished into mirror surfaces. The T-shaped cylinder 2 is cylindrical with a through hole, the inner diameter of the through hole is 4.1 mm, and the peripheral edge of the side wall surface of the upper opening end of the through hole is radially provided with a ring-shaped boss, and the outer diameter of the upper end surface is 5.8 mm. The thickness is 0.5mm, the outer diameter of the lower end surface is 4.8mm, and the length of the T-shaped cylinder 2 is 6mm. A through hole 7 with an inner diameter of 5.0mm is ope...

Embodiment 2

[0035] The sulfur response signal enhancement assembly as described in Example 1, wherein the outer diameter of the quartz rod 1 is 6mm and the length is 19mm, and the length of the quartz rod extended into the flame photometric detector by fixing the stainless steel wire 4 is 16mm. Both the T-shaped cylinder 2 and the circular porous baffle 3 are polyimide. The T-shaped cylinder 2 has a length of 6mm, an inner diameter of 6.1mm, an outer diameter of the upper end surface of the circular platform of 7.8mm, a thickness of 0.5mm, and an outer diameter of the lower end surface of 6.8mm. The outer diameter of the circular porous baffle 3 is 16 mm, the inner diameter of the through hole 7 is 7.0 mm, and the depth is 0.5 mm. The inner diameter of the circular groove 8 is 8.0 mm, and the depth is 0.5 mm. Fifty-two exhaust holes 9 with an inner diameter of 1mm, the exhaust holes 9 are through holes with a spacing of ≥1.5mm. The inner diameter of the metal ring 4 is 6.0mm, and its axi...

Embodiment 3

[0037] The sulfur response signal enhancement assembly as described in Example 1, wherein the outer diameter of the quartz rod 1 is 2 mm and the length is 25 mm, and the length of the quartz rod extended into the flame photometric detector by fixing the stainless steel wire 4 is 20 mm. Both the T-shaped cylinder 2 and the circular porous baffle 3 are ceramics. The T-shaped cylinder 2 has a length of 6mm, an inner diameter of 2.1mm, an outer diameter of the upper end surface of the round platform of 3.8mm, a thickness of 0.5mm, and an outer diameter of the lower end surface of 2.8mm. The outer diameter of the circular porous baffle 3 is 16mm, the inner diameter of the through hole 7 is 3.0mm, and the depth is 0.5mm, and the inner diameter of the circular groove 8 is 4.0mm, and the depth is 0.5mm. Around the circular groove 8, 94 arrays are evenly arranged radially outward The exhaust hole 9 with an inner diameter of 1 mm is a through hole with a spacing ≥ 1.5 mm. The inner dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com