Flower fragrance type cigarette

A flower-flavored and cigarette technology, which is applied in the fields of tobacco, tobacco preparation, and cigar manufacturing, can solve the problems of unreported application in the tobacco industry, and achieve the effects of improving cigarette quality, reducing irritation, and improving oral moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

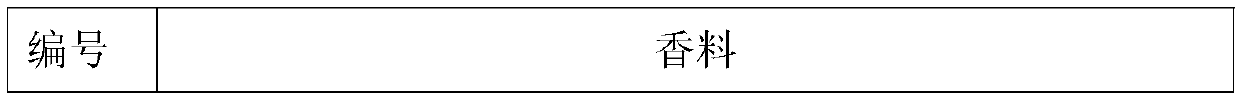

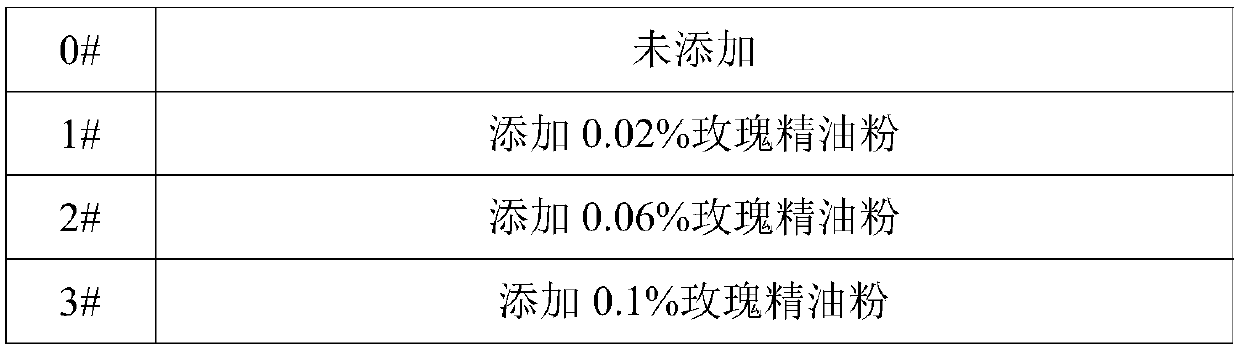

Embodiment 1

[0017] Preparation of rose essential oil powder: Weigh 10g trehalose, 10g sucrose, and 10g glucose in a beaker, mix them evenly, add 3g (1% of the quality of anhydrous trehalose, sucrose, and glucose) water, and heat to In the molten state at 90 or 95°C, remove the beaker and wait for the mixture to cool to 40°C or 50°C, then add (1% of the mass of anhydrous trehalose, sucrose, and glucose) 3g of rose essential oil while stirring. / min or 3500r / min or 5000r / min and stir for 10min or 15min or 20mi for later use; pour distilled water into the funnel of the high-pressure homogenizer, turn on the switch, and turn the secondary homogenizer valve hand clockwise when water flows out of the outlet Turn the wheel to 100bar, then adjust the handwheel of the first-stage homogenizing valve to 600bar or 800bar or 1000bar. After the pressure is stabilized, when the water in the funnel flows to the bottom, pour the rose essential oil mixture continuously to keep samples in the funnel. At the...

Embodiment 2

[0019] The preparation of rose essential oil powder is basically the same as embodiment 1. The difference is: there is no anhydrous trehalose, the mass ratio of sucrose:glucose is 1:2, the added water is 3% of the mass of anhydrous trehalose, sucrose, and glucose, and the added rose essential oil is anhydrous seaweed 14% of the mass of sugar, sucrose, and glucose.

Embodiment 3

[0021] The preparation of rose essential oil powder is basically the same as embodiment 1. The difference is: the mass ratio of anhydrous trehalose: sucrose: glucose is 2:1:1, the added water is 5% of the mass of anhydrous trehalose, sucrose, and glucose, and the added rose essential oil is anhydrous seaweed 28% of the mass of sugar, sucrose and glucose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com