Method for stabilized solidification of mercury-containing waste salt slag by using petrochemical waste alkali slag

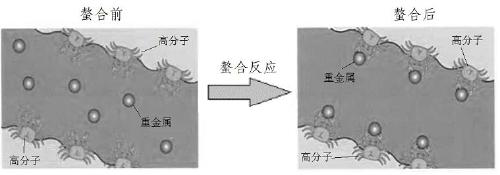

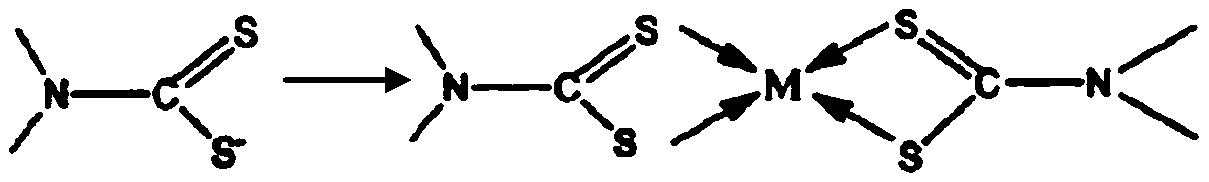

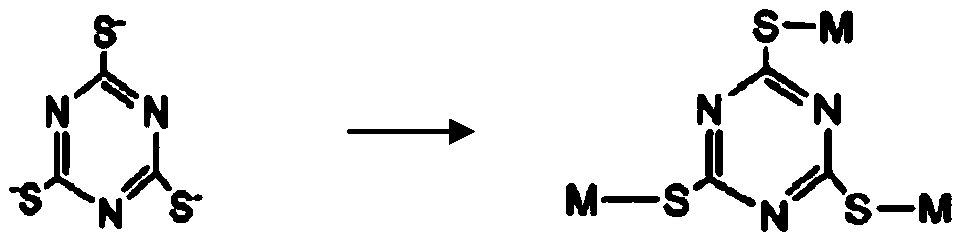

A technology of waste alkali slag and waste salt slag, which is applied in the direction of protection devices against harmful chemicals, can solve the problems of reduced mercury mobility, large volume increase ratio, and poor stabilization effect, and achieves good stable curing effect and increased The effect of small volume ratio and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Mercury-containing waste salt slag: Salt content 68%, water content 5.5%, mercury leaching concentration 73.5mg / l, the content is much higher than the mercury control limit of 0.25mg / L in the "Hazardous Waste Landfill Pollution Control Standard". The stabilization and solidification of mercury-containing waste salt slag is completed according to the following steps:

[0051] (1) Take 5000g of mercury-containing waste salt slag and put it into the first-stage ball mill continuously for one-stage mixing ball milling. At the same time, continuously add the main stabilizer-petrochemical waste alkali slag 750g in atomization mode, and the first-stage mixing ball milling time is 15min. After the material is discharged, it is continuously loaded into the second-stage ball mill and enters the second-stage ball mill. At the same time, the auxiliary stabilizer-heavy metal scavenger 1#5g is continuously added in the form of atomization, and the second-stage mixing and ball milling ...

Embodiment 2

[0055] Mercury-containing waste salt slag: Salt content 68%, water content 5.5%, mercury leaching concentration 73.5mg / l, the content is much higher than the mercury control limit of 0.25mg / L in the "Hazardous Waste Landfill Pollution Control Standard". The stabilization and solidification of mercury-containing waste salt slag is completed according to the following steps:

[0056] (1) Take 5000g of mercury-containing waste salt slag and put it into the first-stage ball mill continuously for a stage of mixed ball milling. At the same time, continuously add the main stabilizer-petrochemical waste alkali slag 250g in the form of atomization, and the first stage of mixed ball milling time is 15min. Continuously put into the second-stage ball mill and enter the second-stage ball mill. At the same time, continuously add auxiliary stabilizer-heavy metal scavenger 1#25g in the form of atomization, and the second-stage mixing ball milling time is 20min.

[0057] (2) Put the mixed mate...

Embodiment 3

[0060] Mercury-containing waste salt slag: Salt content 68%, water content 5.5%, mercury leaching concentration 73.5mg / l, the content is much higher than the mercury control limit of 0.25mg / L in the "Hazardous Waste Landfill Pollution Control Standard". The stabilization and solidification of mercury-containing waste salt slag is completed according to the following steps:

[0061] (1) Take 5000g of mercury-containing waste salt slag and put it into the first stage of ball mill continuously for a stage of mixed ball milling. At the same time, continuously add the main stabilizer-500g of petrochemical waste alkali slag in the form of atomization, mix and ball mill for 15 minutes, and continue after discharging. Put it into the second-stage ball mill and enter the second-stage ball mill. At the same time, add auxiliary stabilizer-heavy metal scavenger 1#15g continuously by atomization, and the second-stage mixing ball milling time is 20min.

[0062] (2) Put the mixed material af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com