A high-vacuum continuous graphite purification device and its application

A high-vacuum and graphite technology, applied in separation methods, carbon compounds, inorganic chemistry, etc., can solve the problems of discontinuous production, damage to the plastic layer of the inner lining of the drum, and increased maintenance costs, so as to improve the purification temperature and purification efficiency. It is beneficial to the promotion of industrialization and the effect of improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

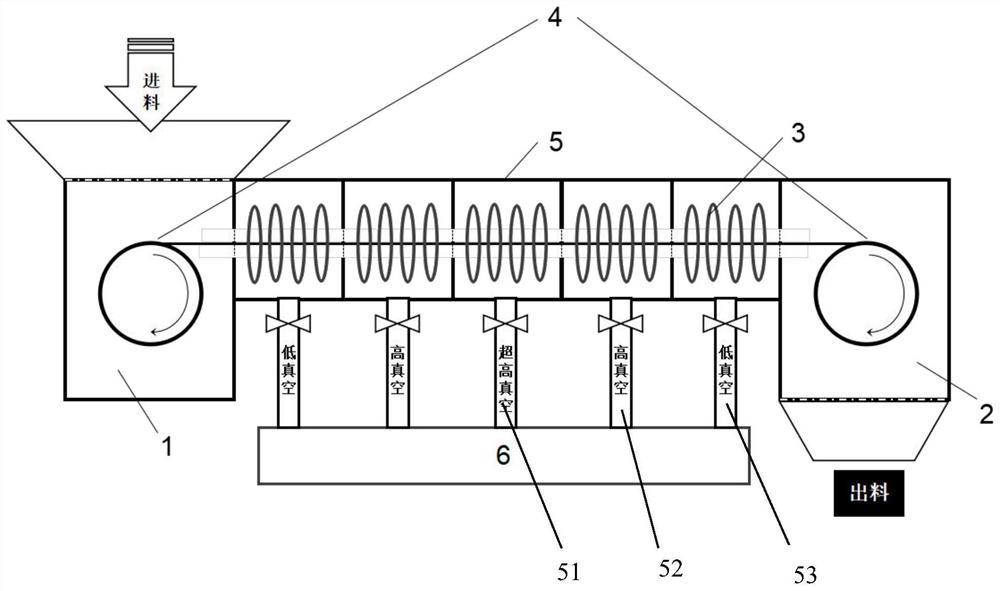

[0045] A high vacuum continuous graphite purification device, such as figure 1 As shown, it includes: a feeding chamber 1, a discharging chamber 2, an induction heating device 3, a transmission device 4, a differential vacuum chamber 5, and an air pump group 6.

[0046]The transmission device 4 is arranged horizontally, and its material is graphite. During work, the graphite ore is transported from the feeding chamber 1 to the discharging chamber 2; the induction heating device 3 is arranged around the periphery of the conveying device 4; the heating section of the induction heating device 3 is externally connected to the air pump group 6 through the pipeline; the heating section is installed on both sides There is a differential vacuum chamber 5 communicating with it; the differential vacuum chamber 5 includes 5 chambers, and the vacuum degree in the chamber decreases from the center to both sides, including an ultra-vacuum chamber 51, a high-vacuum chamber 52 and a low-vacuu...

Embodiment 2

[0053] A high-vacuum continuous graphite purification device is different from Example 1 in that:

[0054] The differential vacuum chamber 5 includes four chambers connected in sequence.

[0055] A kind of application of high vacuum continuous graphite purification device in graphite purification, different from embodiment 1 is:

[0056] 1) The heating method of the induction heating device in step (1) is silicon molybdenum rod heating, and the preheating temperature is 450°C;

[0057] 2) Step (3) does not include an ultra-high vacuum chamber, and the vacuum degree in the high vacuum chamber is 10 -3 Pa;

[0058] 3) The heating temperature in step (3) is 1800°C.

Embodiment 3

[0060] A high vacuum continuous graphite purification device is the same as the device described in Example 1.

[0061] A kind of application of high vacuum continuous graphite purification device in graphite purification, different from embodiment 1 is:

[0062] 1) The heating method of the induction heating device in step (1) is induction heating coil heating, and the preset heating temperature is 600°C;

[0063] 2) The vacuum degree of the low vacuum chamber in step (1) is 10Pa;

[0064] 3) The vacuum degree of the ultra-high vacuum chamber in step (3) is 10 -3 Pa;

[0065] 4) The heating temperature in step (3) is 1200°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com