Application of lanthanum-modified chiral nematic mesoporous silicon catalyst in synthesis of borneol

A chiral nematic, mesoporous silicon technology, used in catalyst activation/preparation, physical/chemical process catalysts, hydroxyl compound preparation, etc. The effect of production cost, reduced equipment requirements, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

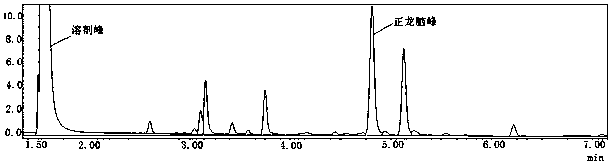

Image

Examples

Embodiment 1

[0026] Embodiment 1: The method for synthesizing orthoborneol of this lanthanum-modified chiral nematic mesoporous silicon catalyst is as follows:

[0027] (1) Take 10g of microcrystalline cellulose (MCC) and put it into 100g of sulfuric acid with a mass concentration of 60% for ultrasonic treatment for 30 minutes. The ultrasonic temperature does not exceed 40°C, then hydrolyze it under magnetic stirring and water bath constant temperature of 40°C for 30 minutes, and then ultrasonically treat it for 1h. , the ultrasonic temperature does not exceed 40°C; add 500mL ultrapure water to the mixture, sonicate for 30min and the temperature does not exceed 40°C, let it stand for 24h, collect the supernatant by centrifugation, put the supernatant in a dialysis bag and dialyze in ultrapure water to The pH in the bag is 2.5, and the liquid in the bag is collected to obtain a nanocrystalline cellulose (NCC) suspension;

[0028] (2) Using orthomethyl silicate (TMOS) as the silicon source a...

Embodiment 2

[0033] Embodiment 2: The method for synthesizing orthoborneol of this lanthanum-modified chiral nematic mesoporous silicon catalyst is as follows:

[0034] (1) Take 7g of microcrystalline cellulose (MCC) and put it into 100g of sulfuric acid with a mass concentration of 65% for ultrasonic treatment for 25 minutes. The ultrasonic temperature should not exceed 40°C, then hydrolyze for 25 minutes under magnetic stirring and water bath at a constant temperature of 45°C, and then ultrasonically treat for 2 hours. , the ultrasonic temperature does not exceed 40°C; add 600mL ultrapure water to the mixture, sonicate for 35min and the temperature does not exceed 40°C, let it stand for 25h, centrifuge to collect the supernatant, put the supernatant in a dialysis bag and dialyze in ultrapure water to The pH inside the belt is 2.5, and the liquid in the collection bag is obtained as nanocrystalline cellulose (NCC) suspension;

[0035] (2) Using orthomethyl silicate (TMOS) as the silicon sou...

Embodiment 3

[0038] Embodiment 3: The method for synthesizing orthoborneol by this lanthanum-modified chiral nematic mesoporous silicon catalyst is as follows:

[0039] (1) Take 8g of microcrystalline cellulose (MCC) and put it into 100g of sulfuric acid with a mass concentration of 70% for ultrasonic treatment for 35 minutes. The ultrasonic temperature should not exceed 40°C, then hydrolyze for 35 minutes with magnetic stirring and water bath at a constant temperature of 35°C, and then ultrasonically treat for 3h. , the ultrasonic temperature does not exceed 40°C; add 600mL ultrapure water to the mixture, sonicate for 25min and the temperature does not exceed 40°C, let it stand for 25h, centrifuge to collect the supernatant, put the supernatant in a dialysis bag and dialyze in ultrapure water to The pH inside the belt is 2.3, and the liquid in the collection bag is obtained as nanocrystalline cellulose (NCC) suspension;

[0040] (2) Using orthomethyl silicate (TMOS) as the silicon source ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com