Method for treating and recycling sludge water by ozone and ceramic membrane combined process

A combined process, ceramic membrane technology, applied in the oxidation water/sewage treatment, water/sludge/sewage treatment, water/sewage treatment and other directions, can solve the problem of large area, large dewatering energy consumption, difficult control of chemical conditioning and other problems, to achieve the effect of membrane fouling mitigation and membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

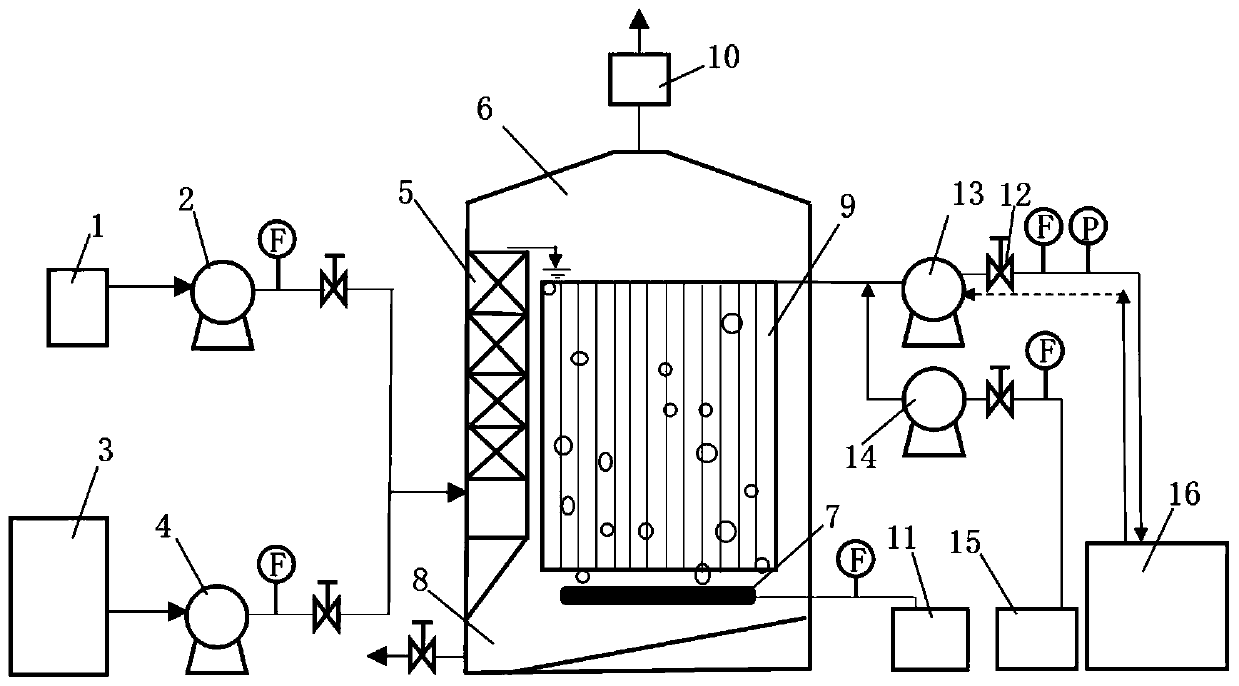

[0029] A kind of ozone and ceramic membrane combined process is to the method for sludge water treatment and recovery, such as figure 1 shown, including the following steps:

[0030] 1) The lifting pump 4 sends the sludge discharge water from the raw water tank 3 to the tubular static mixer 5, and at the same time, the dosing pump 2 pumps the flocculant from the flocculant tank 1 into the mixer. The amount and type of flocculant should be determined according to water quality, reaction time and water volume. The sludge discharge water and flocculant are fully mixed in the tubular static mixer 5 to obtain a mixed solution. The flocculant is polyaluminum chloride.

[0031] 2) The sludge-water mixture overflows from bottom to top in the tubular static mixer 5 into the ceramic membrane tank 6, and the ozone generated by the ozone generator 11 is aerated through the titanium rod 7 below the ceramic membrane module 9, and fully mixed Ozone and muddy water. On the one hand, due t...

Embodiment 2

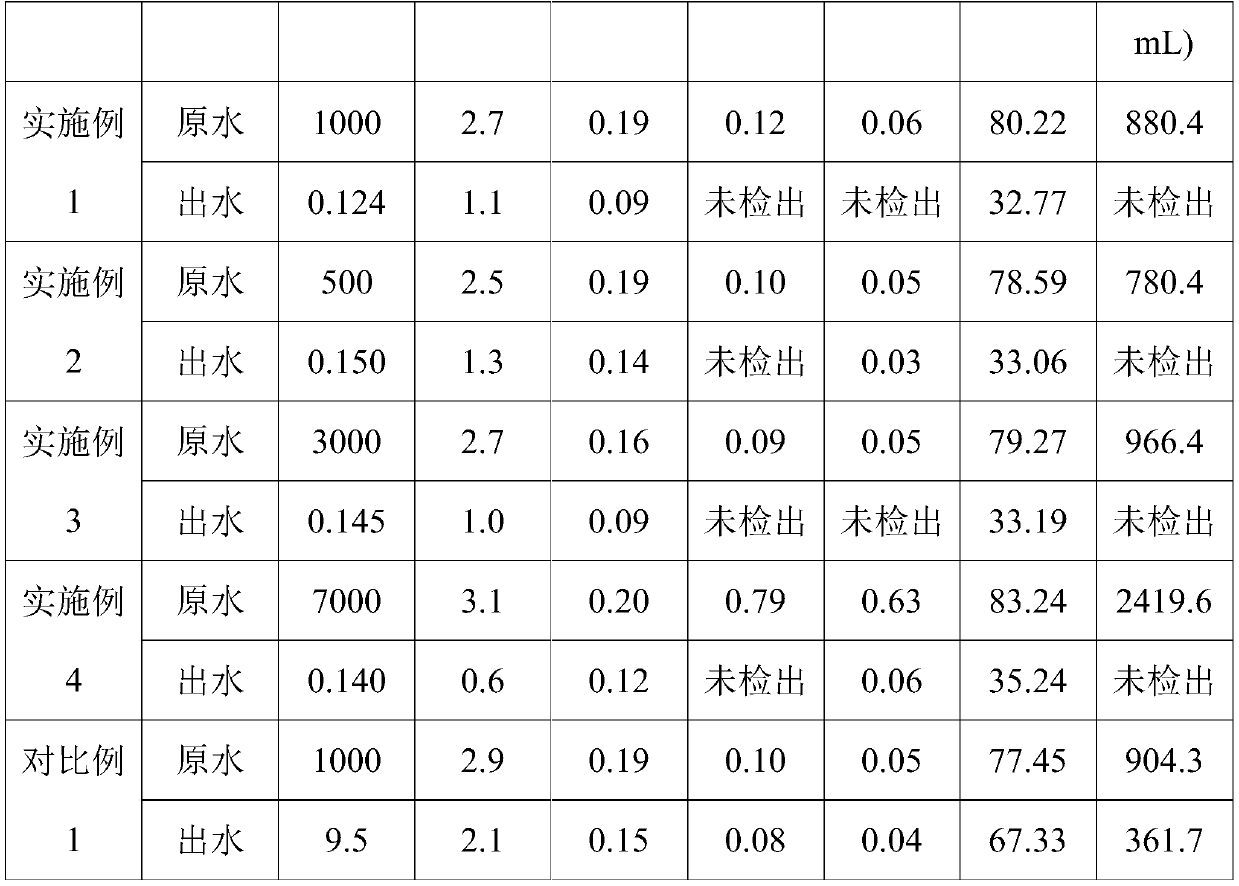

[0038] The steps of embodiment 2 are the same as embodiment 1. In this embodiment, the turbidity of the sludge discharge water is 500NTU, the dosage of PAC is 5mg / L, and the ceramic membrane module 9 is a flat ceramic membrane made of Al 2 o 3 , with an average pore size of 50nm. The membrane flux is 90L / (m 2h), the transmembrane pressure difference during filtration is -10kPa~0kPa, and the ozone dosage is 2mg / L. The backwashing cycle is 120s backwashing every 3600s of muddy water treatment. The cycle of automatic mud discharge is 7200s per running time, and the mud discharge time is 60s.

Embodiment 3

[0040] The steps of embodiment 3 are the same as embodiment 1. In this embodiment, when the mud discharge turbidity is 3000NTU, when the dosage of PAC is 15mg / L, the dosage of ozone is 15mg / L, and the ceramic membrane module 9 is a flat ceramic membrane made of Al 2 o 3 , the average pore size is 80nm. The membrane flux is 60L / (m 2 h), the transmembrane pressure difference during filtration is -20kPa~0kPa, and the backwash cycle is 3600s for every treatment of muddy water for 120s. The cycle of automatic mud discharge is 7200s per running time, and the mud discharge time is 60s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com