A kind of covalent bond type silicon-titanium flocculant and its preparation method and application

A covalent bond and flocculant technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, etc. The removal rate of phosphorus and DOC is not high, and the product has good reproducibility, uniform distribution and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

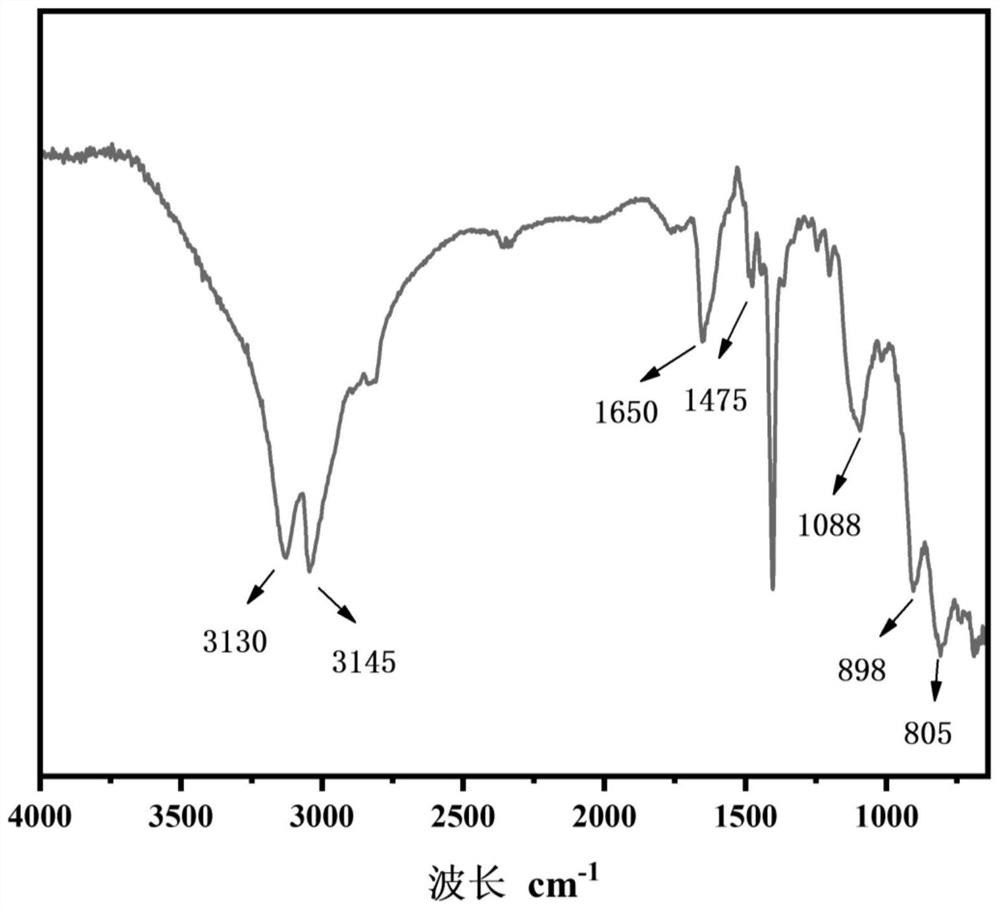

Image

Examples

preparation Embodiment 1

[0026] According to the Si / Ti molar ratio of 0.05, take 100.0 mL of Ti(SO 4 ) 2 Solution, 0.00125mol trimethyl([3-(triethoxysilyl)propyl]ammonium chloride), 12.5mL deionized water were put into a three-necked flask, stirred and mixed evenly at room temperature. Then, stir at 500r / min for 4h at room temperature, and slowly add 12.5mL of NaHCO with a concentration of 1mol / L dropwise. 3 Solution to alkalization degree B is 0.5. The obtained solution was allowed to stand and mature for 48 hours until the reaction was complete, and a flocculant with a total titanium concentration of 0.2 mol / L was obtained.

preparation Embodiment 2

[0028] According to the Si / Ti molar ratio of 0.1, take 25.0 mL of TiCl with a concentration of 1.0 mol / L 4 Solution, 0.0025mol γ-aminopropyltriethoxysilane, and 75.0mL deionized water were put into a three-necked flask, and stirred and mixed evenly at room temperature. Then stir rapidly at room temperature, and slowly add 25.0 mL of NaOH solution with a concentration of 0.5 mol / L dropwise until the degree of alkalinity B is 0.5. The obtained solution was allowed to stand and mature for 24 hours, and after the reaction was complete, a flocculant with a total titanium concentration of 0.2 mol / L was obtained.

preparation Embodiment 3

[0030] According to Si / Ti molar ratio is 0.2, take 50.0mL Ti(SO 4 ) 2 Solution, 0.005mol trimethyl([3-(triethoxysilyl)propyl]ammonium chloride), 75.0mL deionized water were put into a three-necked flask, stirred and mixed evenly at room temperature, and the obtained solution was allowed to stand and mature for 24 hours. After the reaction is complete, a flocculant with a degree of alkalinity B of 0 and a total titanium concentration of 0.2 mol / L is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com