Preparation method of copolymerization modified thermosetting polyimide material

A polyimide and copolymerization modification technology, which is used in the preparation of copolymerization modified thermosetting polyimide materials, can solve problems such as complex curing mechanism, and achieve the advantages of low price, improved market competitiveness and low melt viscosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

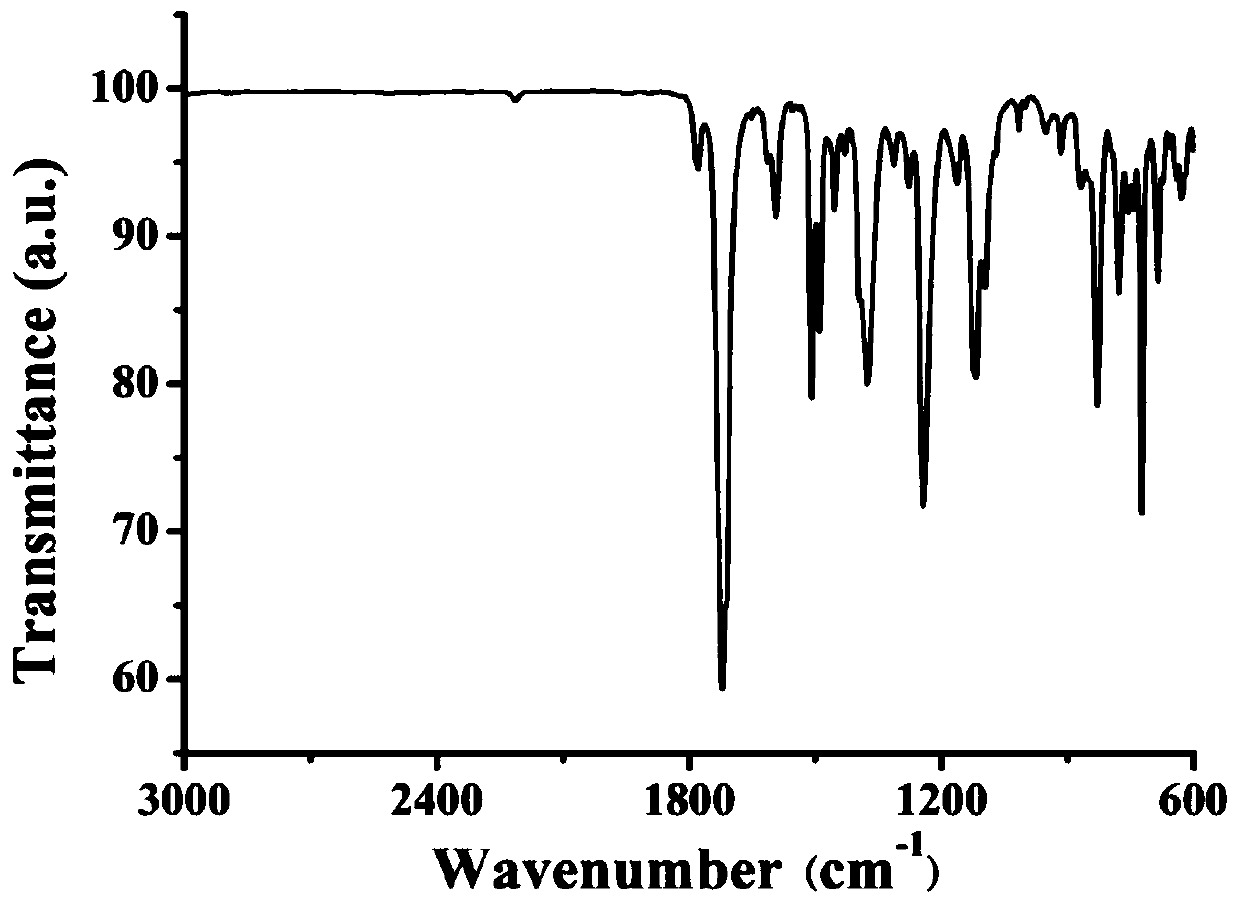

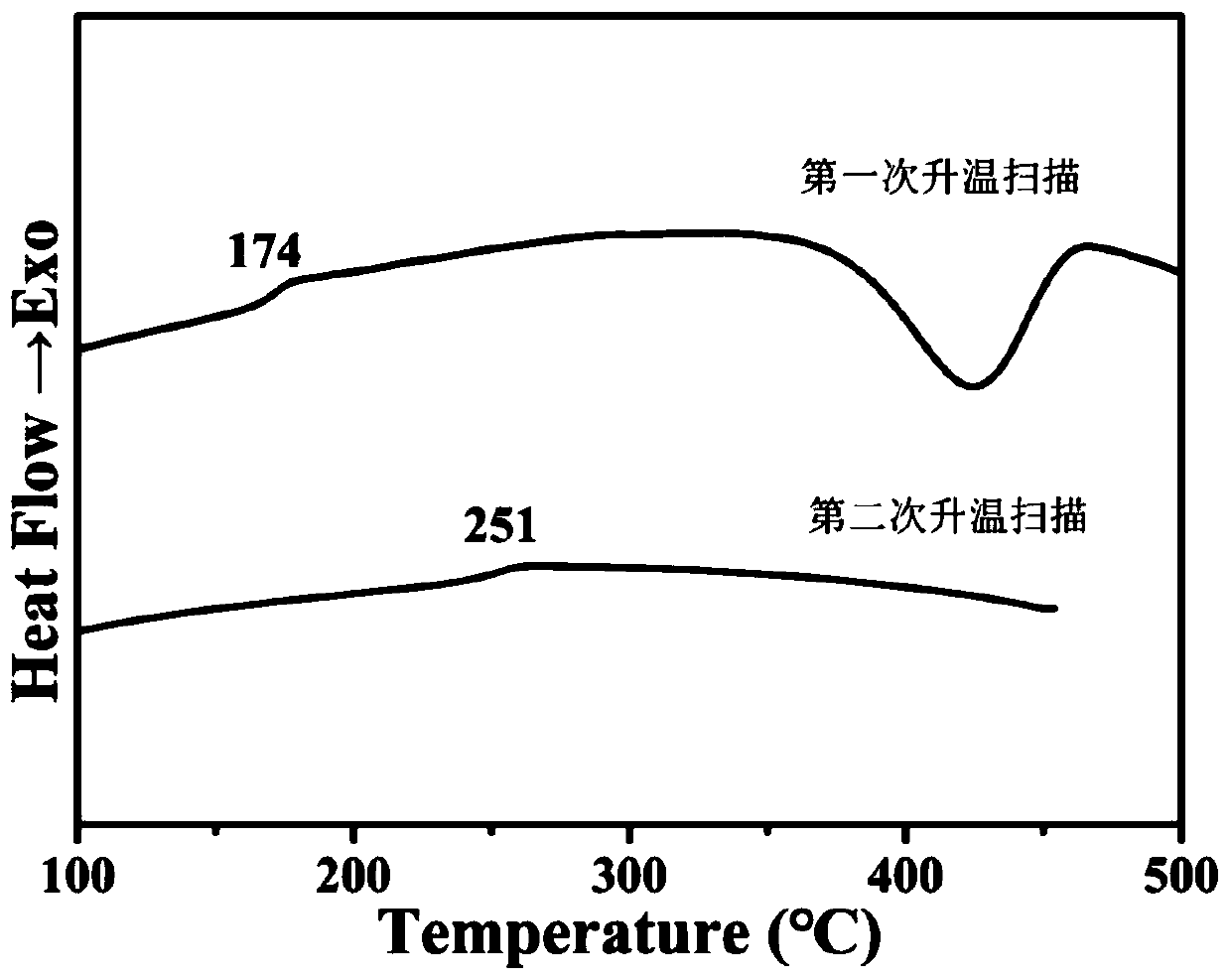

[0033] The preparation method of the copolymerized modified thermosetting polyimide material of the present invention, the detailed steps of the preparation method are as follows:

[0034] a. First, under the protection of nitrogen, add 30g of N-methylpyrrolidone NMP into a three-necked round-bottomed flask with mechanical stirring, and then add 10g of 3,4'-diaminodiphenyl ether and stir to fully dissolve it;

[0035] b. After the 3,4'-diaminodiphenyl ether in step a is completely dissolved, add 4.36g pyromellitic dianhydride PMDA and 6.2g 2,3,3',4'-diphenyl ether tetracarboxylic dianhydride a-ODPA and 30g N-methylpyrrolidone NMP, then react at room temperature, the reaction time is 6h;

[0036] c. Step b. After the reaction is over, add 4.96g of end-capping agent 4-phenylacetylene phthalic anhydride and N-methylpyrrolidone NMP, control the solid content of the solution to 20%, continue to stir and react at room temperature for 24h, and obtain polyamide Acid solution

[0037] d. Heat...

Embodiment 2

[0040] The preparation method of the copolymerized modified thermosetting polyimide material of the present invention, the detailed steps of the preparation method are as follows:

[0041] a. First, under the protection of nitrogen, add 30g of N-methylpyrrolidone NMP into a three-necked round-bottomed flask with mechanical stirring, and then add 10g of 4,4'-diaminodiphenyl ether and stir to fully dissolve;

[0042] b. After the 4,4'-diaminodiphenyl ether in step a is completely dissolved, add 4.36g pyromellitic dianhydride PMDA and 6.2g 2,3,3',4'-diphenyl ether tetracarboxylic dianhydride a-ODPA and 30g N-methylpyrrolidone NMP, then react at room temperature, the reaction time is 5h;

[0043] c. Step b: After the reaction is over, add 4.96g of the end-capping agent 4-phenylacetylene phthalic anhydride and N-methylpyrrolidone NMP, control the solid content of the solution to 20%, continue to stir and react at room temperature for 10 hours, and obtain polyamide after the reaction Acid...

Embodiment 3

[0047] The preparation method of the copolymerized modified thermosetting polyimide material of the present invention, the detailed steps of the preparation method are as follows:

[0048] a. First, under the protection of nitrogen, add 30g of N-methylpyrrolidone NMP into a three-necked round-bottomed flask with mechanical stirring, and then add 10g of 3,4'-diaminodiphenyl ether and stir to fully dissolve it;

[0049] b. After the 3,4'-diaminodiphenyl ether in step a is completely dissolved, add 2.18g pyromellitic dianhydride PMDA and 9.3g 2,3,3',4'-diphenyl ether tetracarboxylic dianhydride a-ODPA and 30g N-methylpyrrolidone NMP, then react at room temperature, the reaction time is 6h;

[0050] c. Step b. After the reaction is over, add 4.96g of end-capping agent 4-phenylacetylene phthalic anhydride and N-methylpyrrolidone NMP, control the solid content of the solution to 20%, continue to stir and react at room temperature for 24h, and obtain polyamide Acid solution

[0051] d. Heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com