Ultra-large-thickness paving and compacting process

A kind of technology, super-large technology, applied in the field of ultra-large thickness paving compaction technology, can solve the problems of weak bonding of upper and lower construction layers, difficulties in longitudinal joint treatment, and low construction efficiency, so as to prevent road diseases and improve rolling flatness The effect of improving the degree and anti-rutting ability and improving the flatness of the base

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

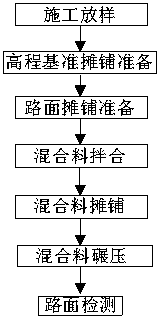

[0040] Such as figure 1 Shown, a kind of ultra-large thickness pavement compaction process, the method comprises the steps:

[0041] S1: Construction stakeout, use the total station to set out the line, mark the design sideline and paving height of the subbase paving, calculate the loose paving height, and make construction marks;

[0042] S2: Elevation reference paving preparation, control the elevation and thickness of the top surface of the paving layer through double reference steel wires, and ensure the elevation, thickness and flatness of the top surface of the paving layer;

[0043] S3: Preparation for road paving. Before paving, ensure that the road surface is clean and tidy, and spray an appropriate amount of combined water on the road surface to moisten the road bed, so as to enhance the bonding firmness and integrity of the subbase and the road bed;

[0044]S4: Mixing of the mixture, calculate the mixing ratio of various raw materials, during the mixing process of ...

Embodiment 2

[0052] The difference from Example 1 is that the thickness of the pavement ranges from 400-600 mm, and the pavement structure includes a 30-35 cm thick cement stabilized macadam base layer + a 5-7 cm thick medium-grain asphalt concrete underlayer + a 5-7 cm thick medium Granular asphalt concrete middle surface layer + 4-6 thick modified rubber asphalt surface layer.

[0053] In step S4, the time from the start of stirring to delivery to the paving site of the well-mixed paving mixture should be controlled within 0.5-1.2 hours.

[0054] In step S4, the temperature of the mixed material is controlled at 150-170° C.; the dry mixing time of rubber particles and stones is 25-35 minutes; the mixing time after adding asphalt and mineral powder is 85-95 minutes;

[0055] In S5, the paving speed should be controlled at 1-4m / min to ensure that the paver works continuously at a constant speed, which can not only ensure compaction but also improve smoothness.

[0056] In S6, the initial ...

Embodiment 3

[0059] On the basis of Embodiments one and two, during the working process of the paver, the truck will import the mixed material into the collecting hopper of the paver, and the scraper conveyor and screw distributor of the paver will mix the mixed material and send it to the ironing machine. Slab material room, after leveling the screed, the screed pre-compacts the mixture and forms a uniform delivery layer, which is further rolled by the road roller.

[0060] During the paving process, various functional factors can affect the quality of pavement paving, but the stress state of the screed plays a decisive role in the entire paving process. The traction arms on the left and right sides of the paver move the screed The screed is hinged with the main machine, and the screed at the rear end of the traction is connected by two oil cylinders; during operation, the rear oil cylinder is in a floating state, and the screed is only connected to the main machine by the drag point of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com