Pole piece with novel conductive agent distribution structure and lithium ion battery comprising pole piece

A conductive agent and pole piece technology, which is applied in the field of pole pieces with a new type of conductive agent distribution structure, can solve the problems of increased polarization, reduced proportion of conductive agent, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0039] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

[0040] The 97.8% formula used in the following examples refers to the positive electrode slurry with a positive electrode active material (lithium cobaltate) content of 97.8%, a conductive agent (carbon black) content of 1%, and a binder (PVDF) cont...

Embodiment 1

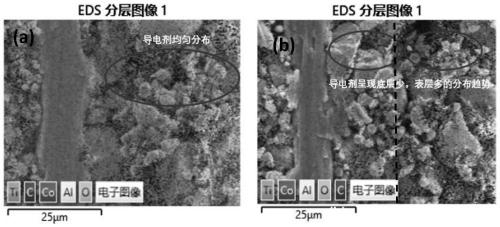

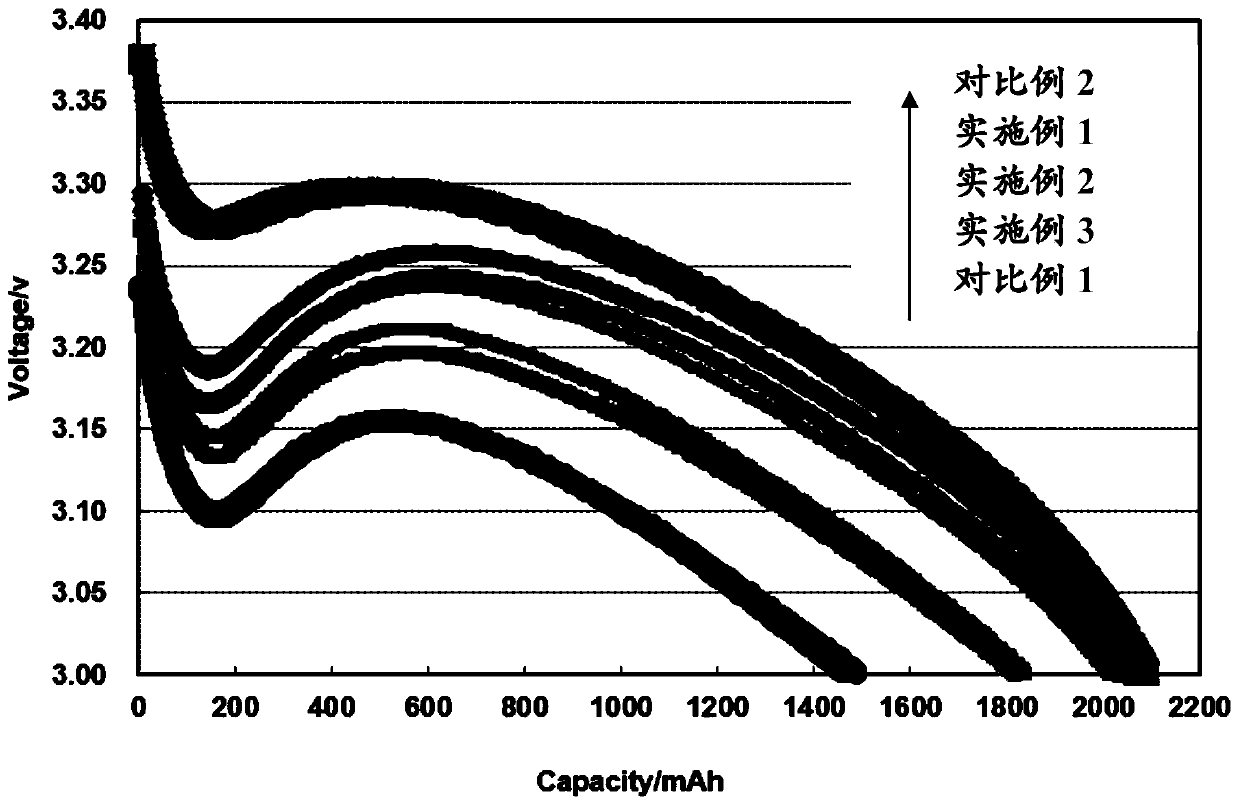

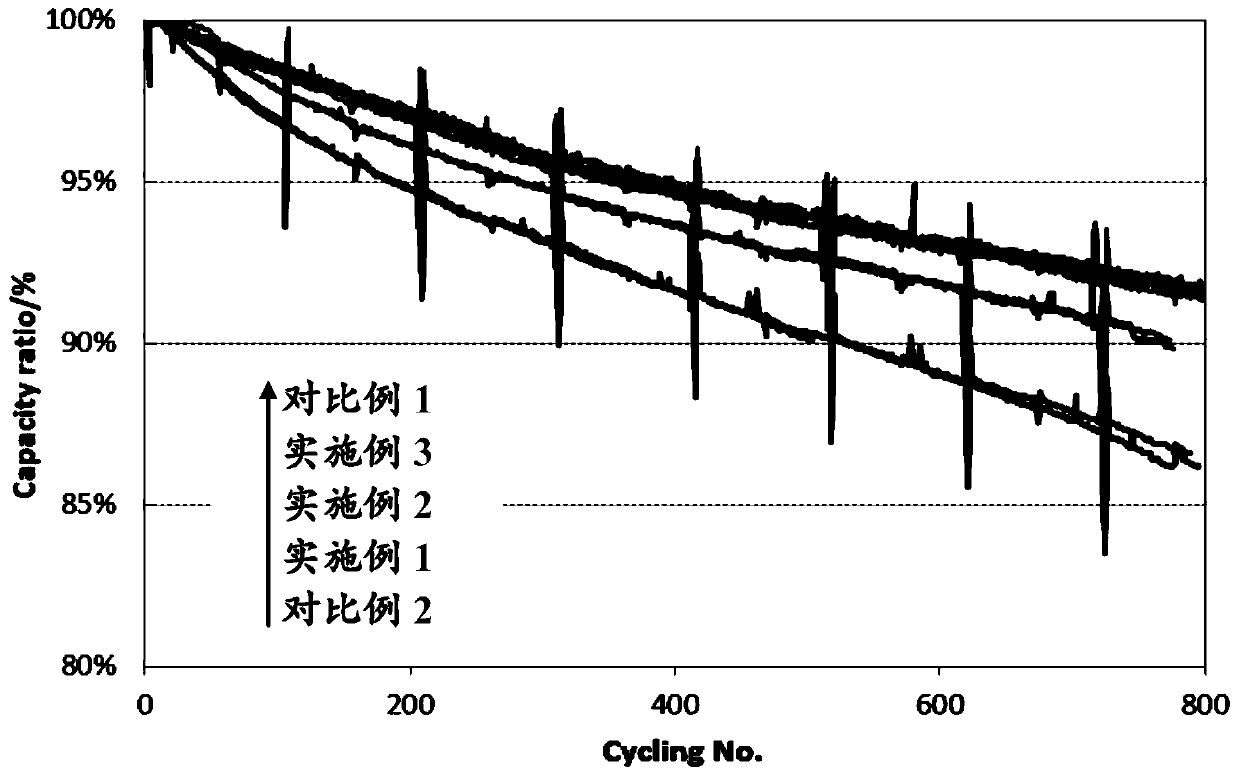

[0051] Two layers of double-layer coating machine are used to coat 97.8% formula and 95.2% formula at the same time, 97.8% formula is coated near the aluminum foil area, and 95.2% formula is coated far away from the aluminum foil area, and the thickness ratio of the two formulas is: d(97.8% ):d(95.2%)=3:7, to obtain a positive electrode sheet with a thickness of 108 μm.

[0052] The preparation of the lithium-ion battery is the same as in Comparative Example 1.

Embodiment 2

[0054] Others are the same as in Example 1, the difference is that the thickness ratio of the two formulations is: d(97.8):d(95.2)=5:5, and a positive electrode sheet with a thickness of 108 μm is obtained.

[0055] The preparation of the lithium-ion battery is the same as in Comparative Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com