Sulfide solid electrolyte material with high stability to lithium, preparation method and application thereof

A solid electrolyte, solid electrolyte technology, applied in the direction of solid electrolyte, non-aqueous electrolyte, non-aqueous electrolyte battery, etc., can solve the problems of battery capacity reduction, chemical instability, service life attenuation, etc., achieve high air stability, improve ionic The effect of conductivity and long stabilization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

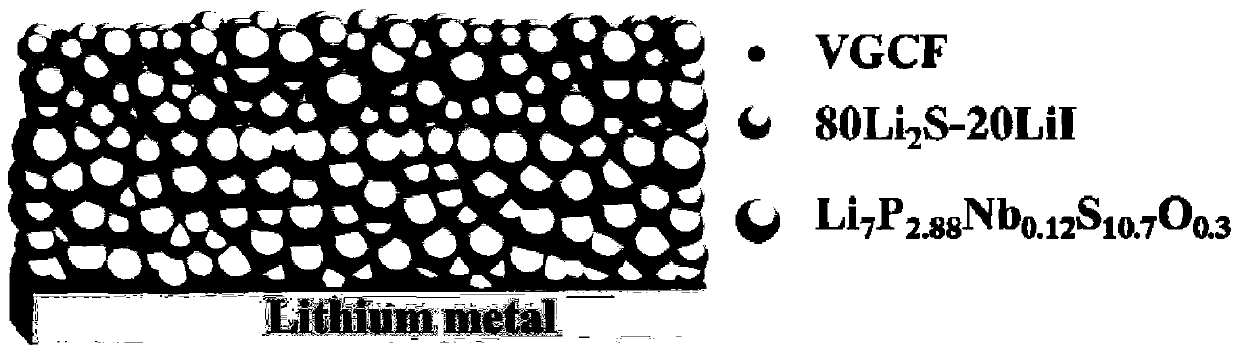

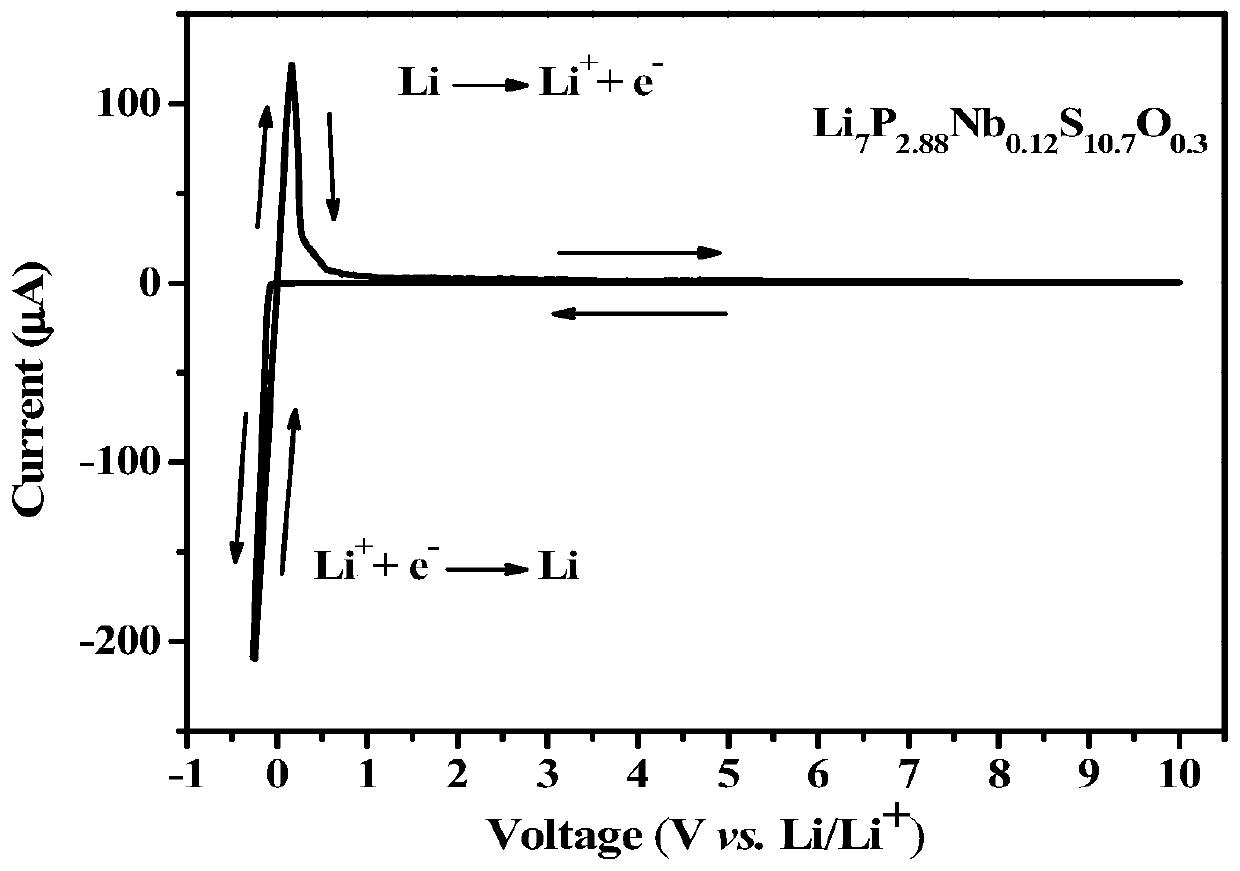

[0037] (1) The present embodiment provides a kind of sulfide solid state electrolyte, and its chemical composition is Li 7 Nb 0.12 P 2.88 S 10.7 o 0.3 , can also be written as a chemical composition of 7Li 2 S 2.88P 2 S 5 0.12Nb 2 o 5 ;

[0038] (2) will Li 2 S, P 2 S 5 and dopant Nb 2 o 5 Mixed according to the molar ratio of 7:2.88:0.12, put into a stainless steel grinding tank protected by argon, the rotating speed of ball milling is 500rpm, and the ball milling time is 30h to obtain the initial solid electrolyte material;

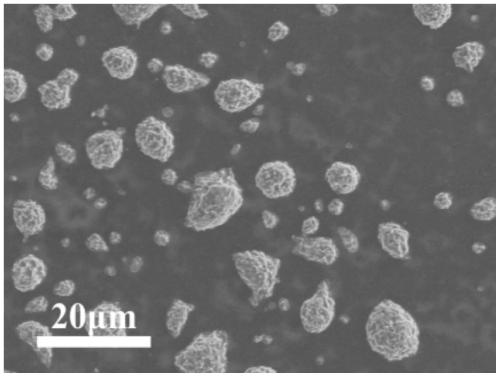

[0039] (3) Put the initial solid electrolyte material obtained in step (2) into a quartz test tube, seal it, and then heat treat it at 250°C for 1 hour, and then grind it into powder to obtain the sulfide solid electrolyte material Li 7 Nb 0.12 P 2.88 S 10.7 o 0.3 (That is, a sulfide solid-state electrolyte material with high stability to lithium).

[0040] (4) Put Li first 2 S and LiI were placed in a ball mill jar and mechanically ...

Embodiment 2

[0048] (1) The present embodiment provides a kind of sulfide solid state electrolyte, and its chemical composition is Li 7 Nb 0.5 P 2.5 S 9.75 o 1.25 , can also be written as a chemical composition of 7Li 2 S 2.5P 2 S 5 0.5Nb 2 o 5 ;

[0049] (2) will Li 2 S, P 2 S 5 and dopant Nb 2 o 5 Mix according to the molar ratio of 7:2.5:0.5, put it into an argon-protected stainless steel grinding tank, the ball milling speed is 550rpm, and the ball milling time is 40h to obtain the initial solid electrolyte material;

[0050] (3) Put the initial solid electrolyte material obtained in step (2) into a quartz test tube, seal it, and then heat treat it at 240°C for 2 hours, and then grind it into powder to obtain the sulfide solid electrolyte material Li 7 Nb 0.5 P 2.5 S 9.75 o 1.25 .

[0051] (4) Put Li first 2 S and LiI were placed in a ball milling tank and mechanically milled for 15 hours under an argon atmosphere, with a rotational speed set at 500 rpm; 7 Nb 0.5 ...

Embodiment 3

[0054] (1) The present embodiment provides a kind of sulfide solid state electrolyte, and its chemical composition is Li 7 W 0.5 P 2.5 S 9.75 o 1.5 , can also be written as a chemical composition of 7Li 2 S 2.5P 2 S 5 ·1WO 3 ;

[0055] (2) will Li 2 S, P 2 S 5 and dopant WO 3 Mix according to the molar ratio of 7:2.5:1, put it into an argon-protected stainless steel grinding tank, the ball milling speed is 450rpm, and the ball milling time is 40h to obtain the initial solid electrolyte material;

[0056] (3) Put the initial solid electrolyte material obtained in step (2) into a quartz test tube, seal it, and then heat treat it at 250°C for 2 hours, and then grind it into powder to obtain the sulfide solid electrolyte material Li 7 W 0.5 P 2.5 S 9.75 o 1.5 .

[0057] (4) Put Li first 2 S and LiI were placed in a ball mill jar and mechanically milled for 15 hours under an argon atmosphere, with a rotational speed set at 550 rpm; 7 W 0.5 P 2.5 S 9.75 o 1.5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com