Nanometer bismuth catalyst and preparation method and application thereof

A technology of nano-bismuth and catalyst, which is applied in the field of nano-bismuth catalyst and its preparation, which can solve the problems of low ammonia efficiency and catalyst low activity, and achieve the effect of overcoming low efficiency and low current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

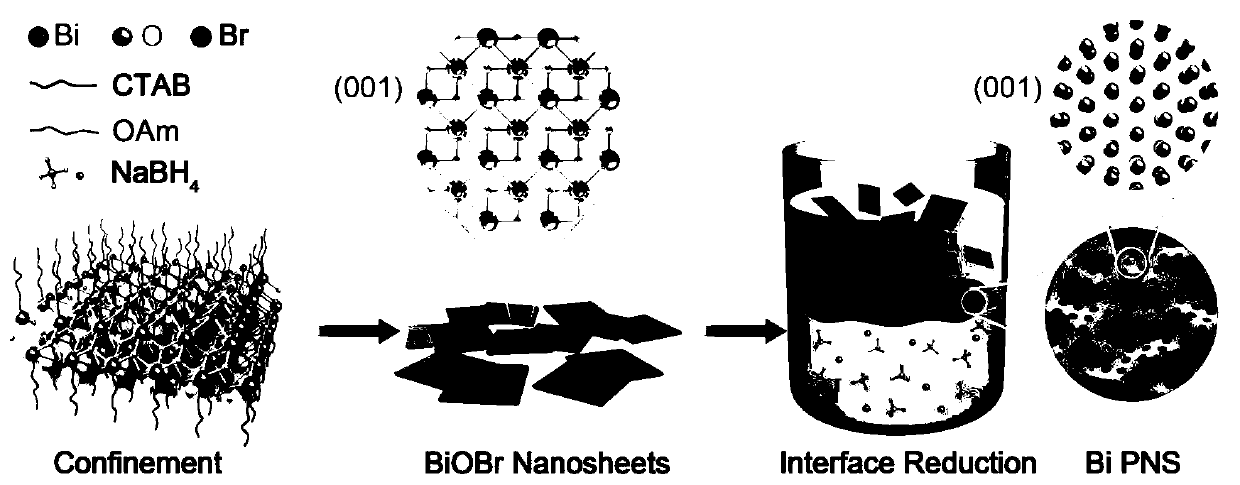

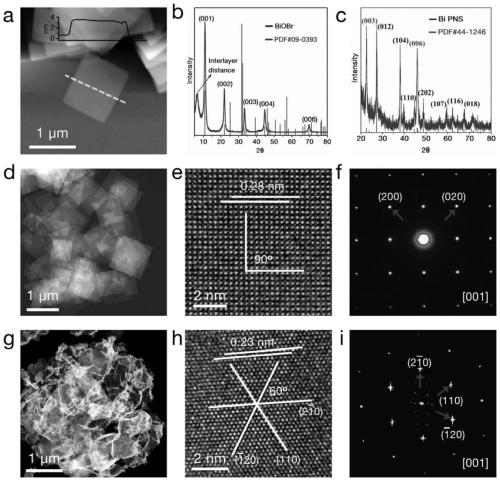

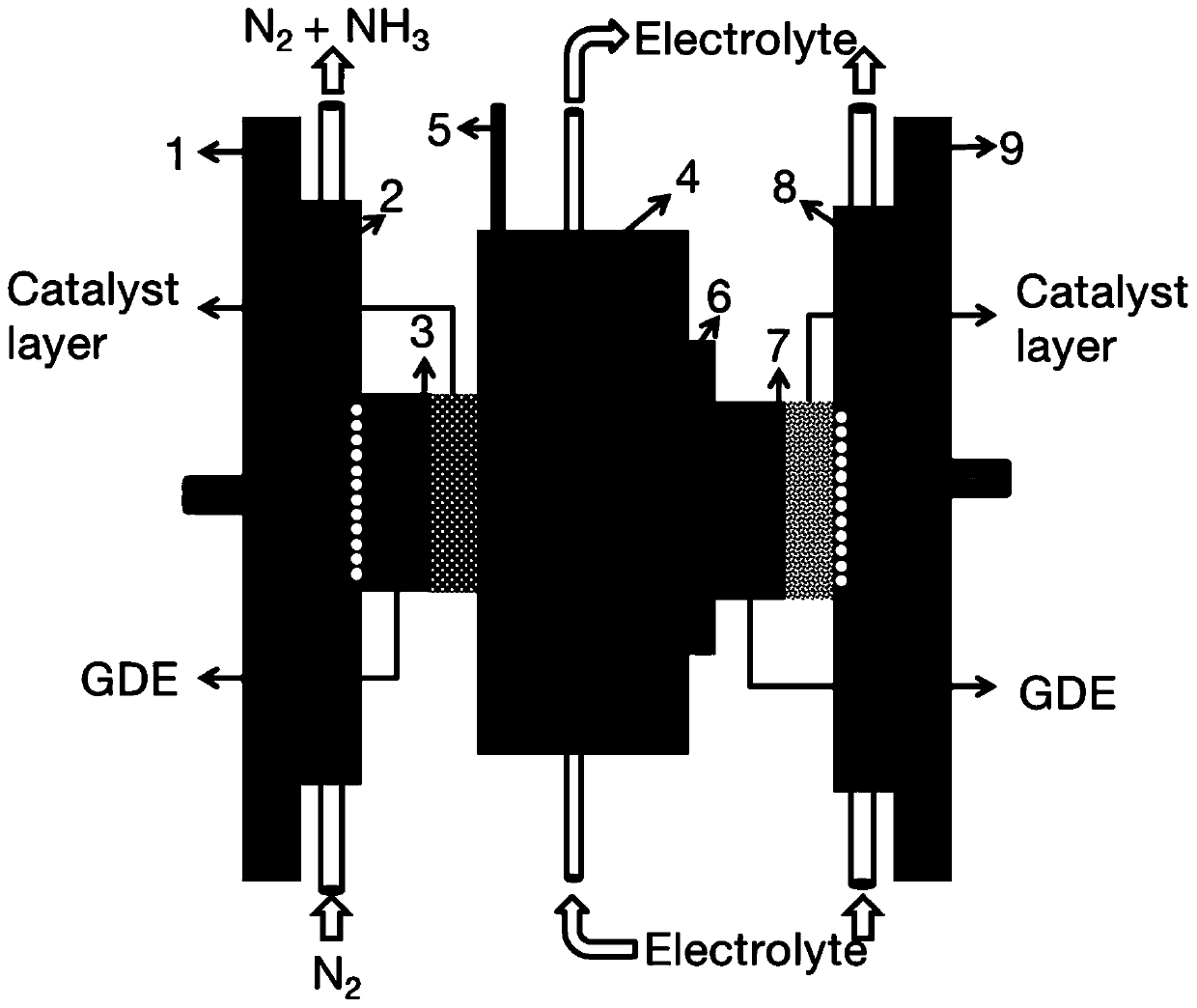

[0030] A nano-bismuth catalyst, comprising a carbon cloth substrate and bismuth porous nanosheets (001) coated on the carbon cloth, the loading of bismuth porous nanosheets is 0.8mg / cm 2 .

[0031] The preparation method of above-mentioned nano-bismuth catalyst comprises the following steps:

[0032] (1) Preparation of precursor bismuth oxybromide dispersion

[0033] Mix bismuth nitrate pentahydrate and hexadecyltrimethylammonium bromide at a molar ratio of 0.25:1 and place in oleylamine, disperse by ultrasonication for 2 hours to form a homogeneous solution, transfer to a solvothermal reaction kettle, and stir at 170°C for reaction 12h, the stirring rate was 350r / min, after the reaction was completed, it was washed with n-hexane, and finally dispersed in n-hexane to obtain;

[0034] (2) Preparation of active agent bismuth porous nanosheets

[0035] Mix 20mL precursor bismuth oxybromide dispersion with 60mL reducing solution, stir for 1h, after the reaction is complete, was...

Embodiment 2

[0043] A nano-bismuth catalyst, comprising a carbon cloth substrate and bismuth nano-spherical particles coated on the carbon cloth, the loading of bismuth nano-spherical particles is 1.0mg / cm 2 .

[0044] The preparation method of above-mentioned nano-bismuth catalyst comprises the following steps:

[0045] (1) Preparation of Bismuth Nanospherical Particles

[0046] Dissolve a certain quality of bismuth nitrate pentahydrate in a mixed solution of 1-hexadecylsulfur and 1-octadecene with a volume ratio of 1:1, the total volume of the solution is 10mL, and the concentration of bismuth nitrate pentahydrate in the mixed solution is generally 5-50mg / mL (preferably 15mg / mL), and then heated to 180°C with a heating rate of 5-6°C·min -1 , kept under an inert gas such as argon or nitrogen for 5 minutes. After the reaction solution is naturally cooled to room temperature, the product is collected by centrifugation to obtain bismuth nano-spherical particles;

[0047] All the above oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com