Composite iron-based catalyst for catalytic oxidation and application thereof

An iron-based catalyst, catalytic oxidation technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, oxidized water/sewage treatment, etc., can solve the problem of high cost and achieve strong tolerance , high reaction speed, not easy to be polluted and poisoned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Iron powder is selected and pretreated. The pretreatment refers to using 1mol / L NaOH to degrease and using 1% H 2 SO 4 Remove rust and other contaminants.

[0023] Take 70% of pretreated iron powder, mix with 10% carbon powder, 19.5% iron oxyhydroxide, 0.5% transition metal ingredients (Cu, Mn, Ni, Co, Ti, etc.), and use 30% H 2 o 2 Soak in the solution, passivate on a shaker for 8.0 to 10.0 hours, take it out, wash and dry, and obtain an iron-based composite catalyst, the main component of which is iron oxyhydroxide, expressed as FeOOH.

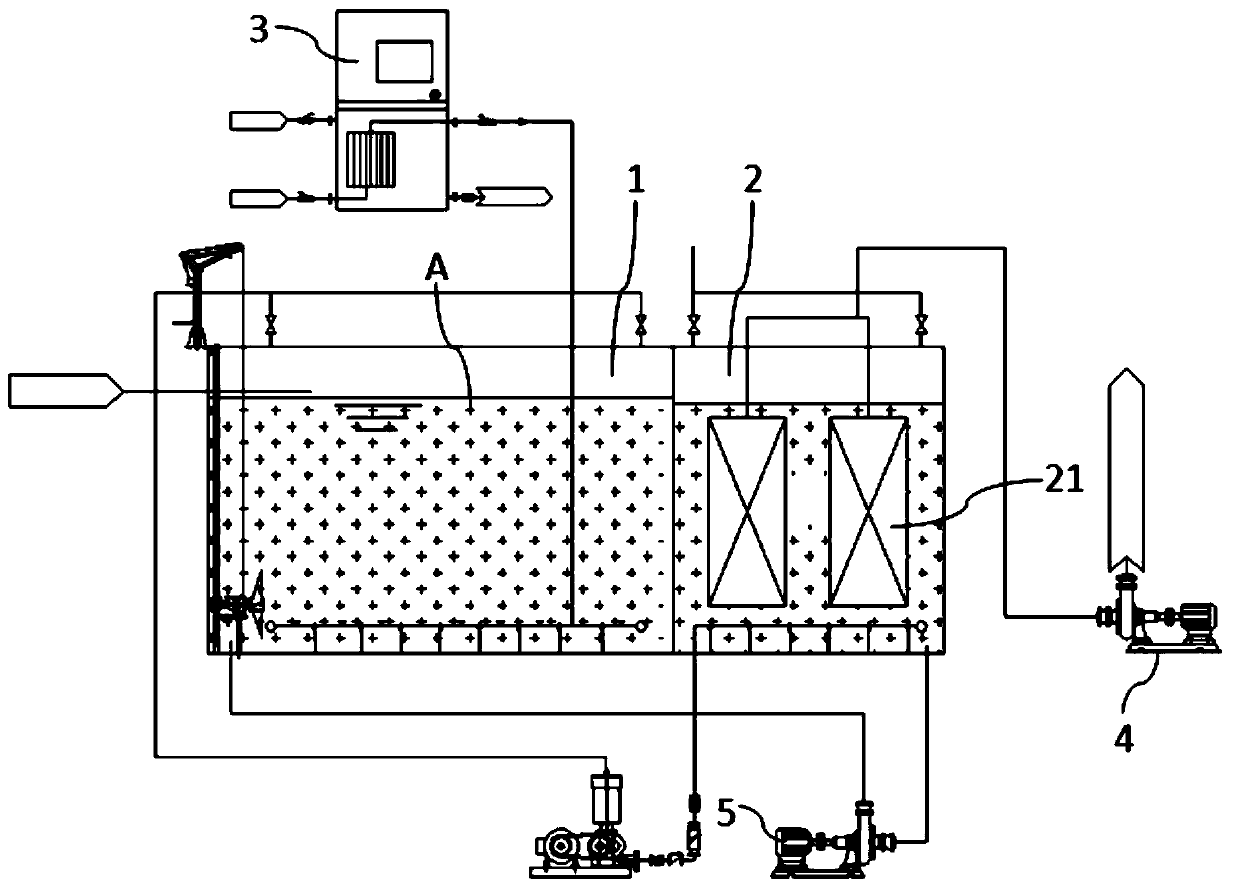

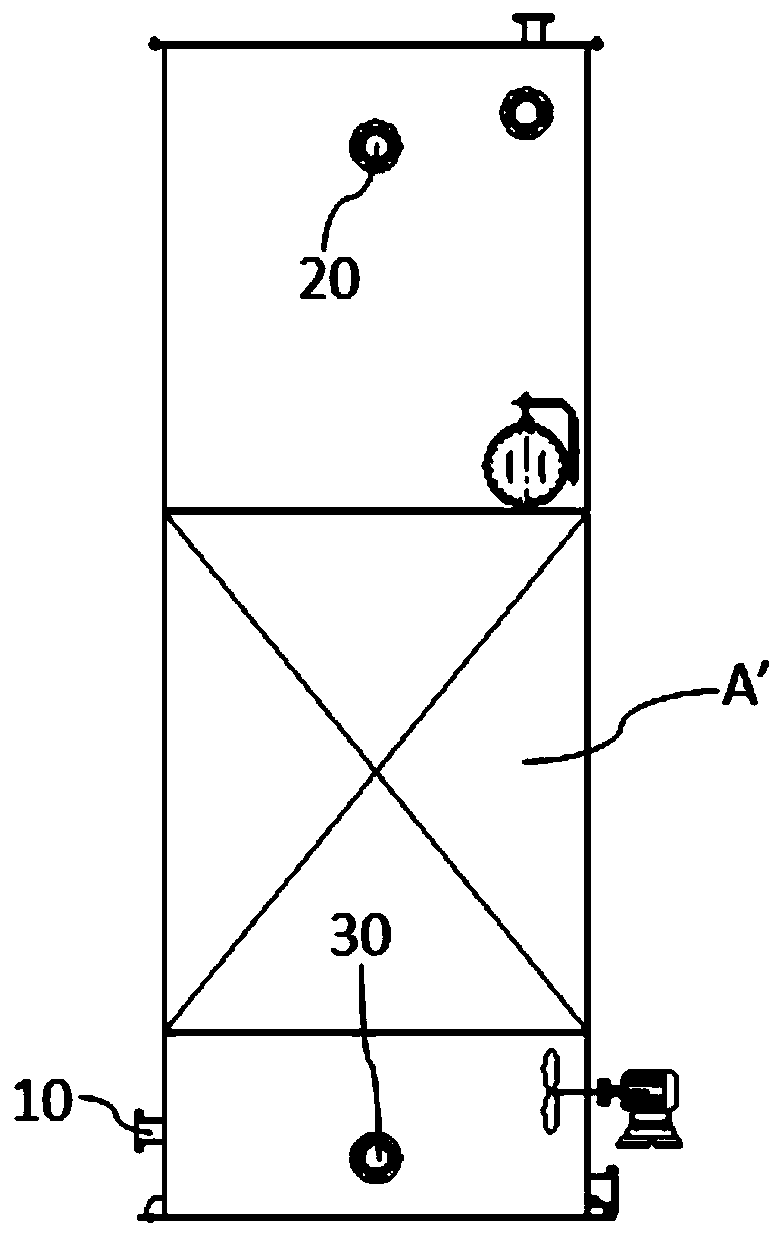

[0024] through as figure 1 The membrane separation reactor shown performs catalytic oxidation. Wherein, the membrane separation reactor includes a catalytic reaction tank 1 carrying an iron-based composite catalyst A and a membrane separation tank 2 communicated with the catalytic reaction tank 1 through a perforated partition wall 1a, and the ozone generator 3 is communicated with the catalytic reaction tank 1 To feed O into th...

Embodiment 2

[0027] Iron powder pretreatment step is the same as embodiment 1.

[0028] Take 70% of the pretreated iron powder, mix it with 30% carbon powder, and use 30% H 2 o 2 Soak in the solution, passivate on a shaker for 8.0 to 10.0 hours, take it out, wash and dry, and obtain an iron-based composite catalyst, the main component of which is iron oxyhydroxide, expressed as FeOOH.

[0029] The catalytic oxidation reactor is the same as in Example 1.

[0030] Catalytic O 3 Oxidation performance: The COD of the secondary biochemical effluent of a sewage treatment station in an electronics factory is 90mg / L. o 3 Catalytic oxidation reaction residence time is 40min, O 3 The dosage is 75mg / l, and the concentration of the prepared iron-based composite catalyst is 8g / L. After the catalytic oxidation reaction, the COD is 40mg / L, the removal rate is 55%, the total iron content in the effluent is less than 0.5mg / l, the effluent water quality and the service life of the catalyst have very g...

Embodiment 3

[0032] Iron powder pretreatment step is the same as embodiment 1.

[0033] Take 90% of the pretreated iron powder, mix it with 10% carbon powder, and use 30% H 2 o 2 Soak in the solution, passivate on a shaker for 8.0 to 10.0 hours, take it out, wash and dry, and obtain an iron-based composite catalyst, the main component of which is iron oxyhydroxide, expressed as FeOOH.

[0034] The catalytic oxidation reactor is the same as in Example 1.

[0035] Catalytic O 3 Oxidation performance: The COD of the secondary biochemical effluent of a sewage treatment station in a paint chemical factory is 100mg / L. o 3 Catalytic oxidation reaction residence time is 50min, O 3 The dosage is 80mg / l, and the concentration of the prepared iron-based composite catalyst is 12g / L. After the catalytic oxidation reaction, the COD is 55mg / L, the removal rate is over 40%, the total iron content in the effluent is less than 0.5mg / l, the effluent water quality and the service life of the catalyst ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com