High-performance heterogeneous composite catalyst for electrocatalytic hydrogen evolution and preparation method thereof

A composite catalyst and electrocatalysis technology, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, electrodes, etc., can solve the problems of poor electrical conductivity, etc., and achieve the effects of improving hydrogen evolution performance, easy control of reaction conditions, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

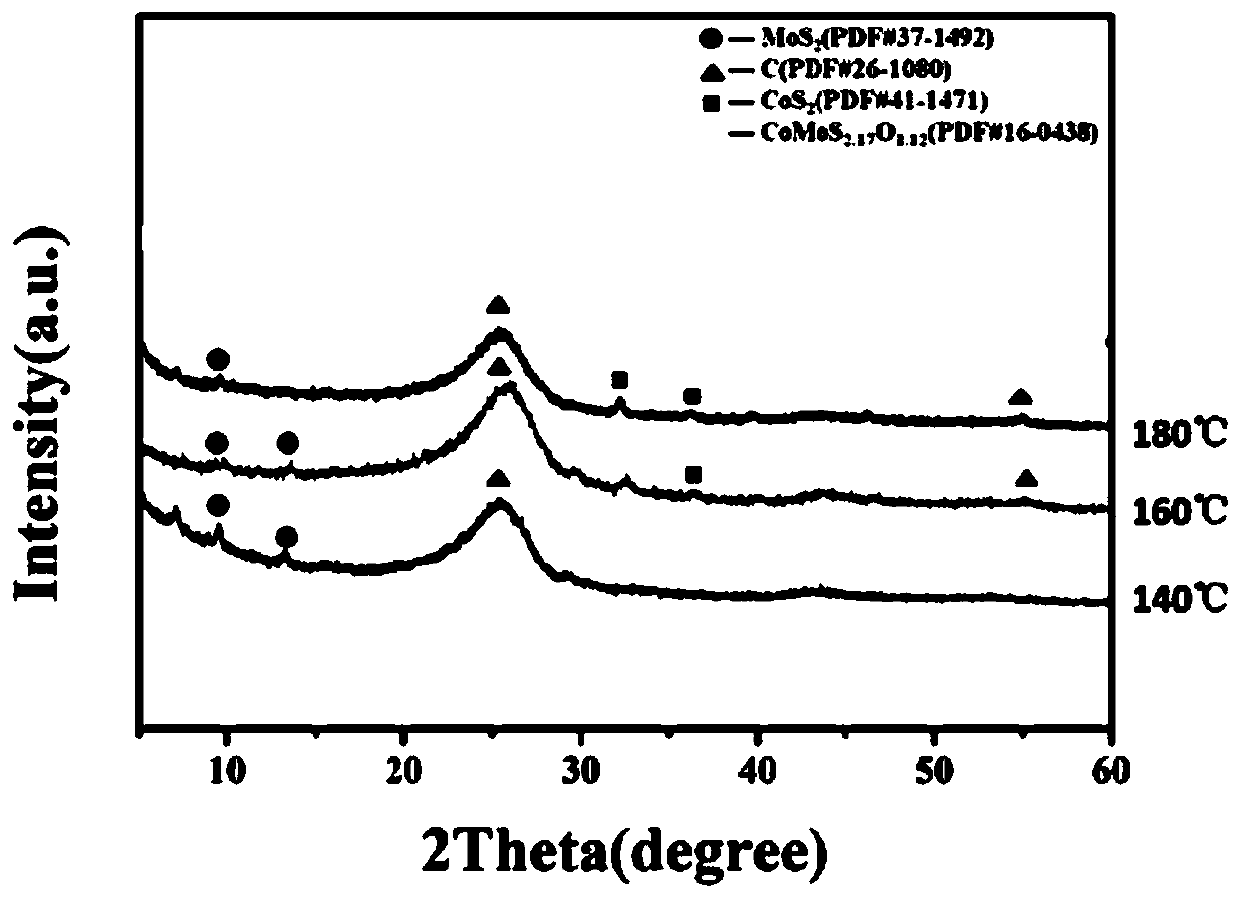

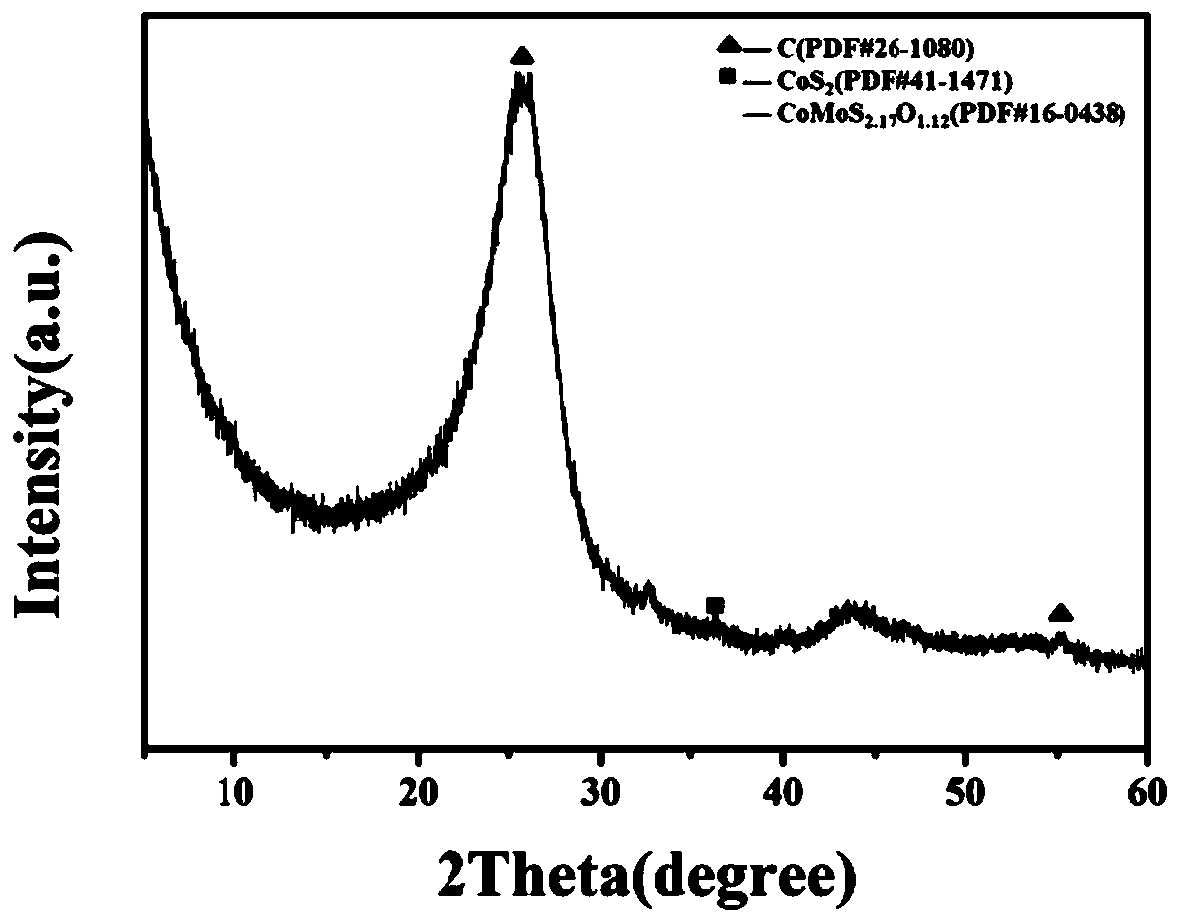

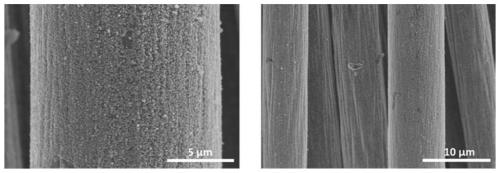

[0039] A MoS grown on carbon cloth 2 / CoS 2 / CoMoS 2.17 o 1.12 The preparation method of composite catalyst, its preparation method is as follows:

[0040] (1) Pre-treat the carbon cloth, place the carbon in concentrated nitric acid and soak it at room temperature for 30 minutes, then transfer it to the reaction kettle and heat it in water at 120°C for 30 minutes, then cool it to room temperature with the furnace, and take out the carbon cloth with an ultra-pure Wash with water.

[0041] (2) The carbon cloth in step (1) was ultrasonically cleaned in ultrapure water and ethanol for 30 min, respectively, and dried in an oven at 60°C for later use.

[0042] (3) Take thiourea, cobalt chloride, and ammonium molybdate tetrahydrate and dissolve them in 20 mL of ultrapure water with an electronic balance, control the (Co / Mo) molar ratio of cobalt chloride and ammonium molybdate to be 1, and The concentration in aqueous solution is 0.014mol / L, ammonium molybdate tetrahydrate ([(NH...

Embodiment 2

[0052] A MoS grown on carbon cloth 2 / CoS 2 / CoMoS 2.17 o 1.12 The preparation method of composite phase catalyst material, its preparation method is as follows:

[0053] (1) Pretreat the carbon cloth. The pretreatment step is to first place the carbon in concentrated nitric acid and soak it at room temperature for 30 minutes, then transfer it to the reaction kettle and heat it in water at 120°C for 30 minutes, and cool it to room temperature with the furnace. The cloth was taken out and washed with ultrapure water.

[0054] (2) The carbon cloth in step (1) was ultrasonically cleaned in ultrapure water and ethanol for 30 min, respectively, and dried in an oven at 60°C for later use.

[0055] (3) a takes by weighing thiourea with electronic balance, cobalt chloride, ammonium molybdate is dissolved in 20mL ultrapure water, and the control Co / Mo mol ratio is 1, and the concentration of cobalt chloride in aqueous solution is 0.014mol / L, The concentration of ammonium molybdate...

Embodiment 3

[0064] A method for preparing a heterogeneous composite catalyst material grown on carbon cloth, the preparation method is as follows:

[0065] (1) Pretreat the carbon cloth. The pretreatment step is to first place the carbon in concentrated nitric acid and soak it at room temperature for 30 minutes, then transfer it to the reaction kettle and heat it in water at 120°C for 30 minutes, and cool it to room temperature with the furnace. The cloth was taken out and washed with ultrapure water.

[0066] (2) The carbon cloth in step (1) was ultrasonically cleaned in ultrapure water and ethanol for 30 min, respectively, and dried in an oven at 60°C for later use.

[0067] (3) Use an electronic balance to weigh thiourea, cobalt chloride, and ammonium molybdate and dissolve them in 20 mL of ultrapure water, and control the Co / Mo molar ratio to 0.3-4:1 (0.3:1, 0.5:1, 2:1 , 4:1), the concentration of thiourea was 0.04mol / L, the concentration of ammonium molybdate was 0.002mol / L, and sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com