Method for assembling periodic nanostructure on plane or curved surface by utilizing soft matter interface

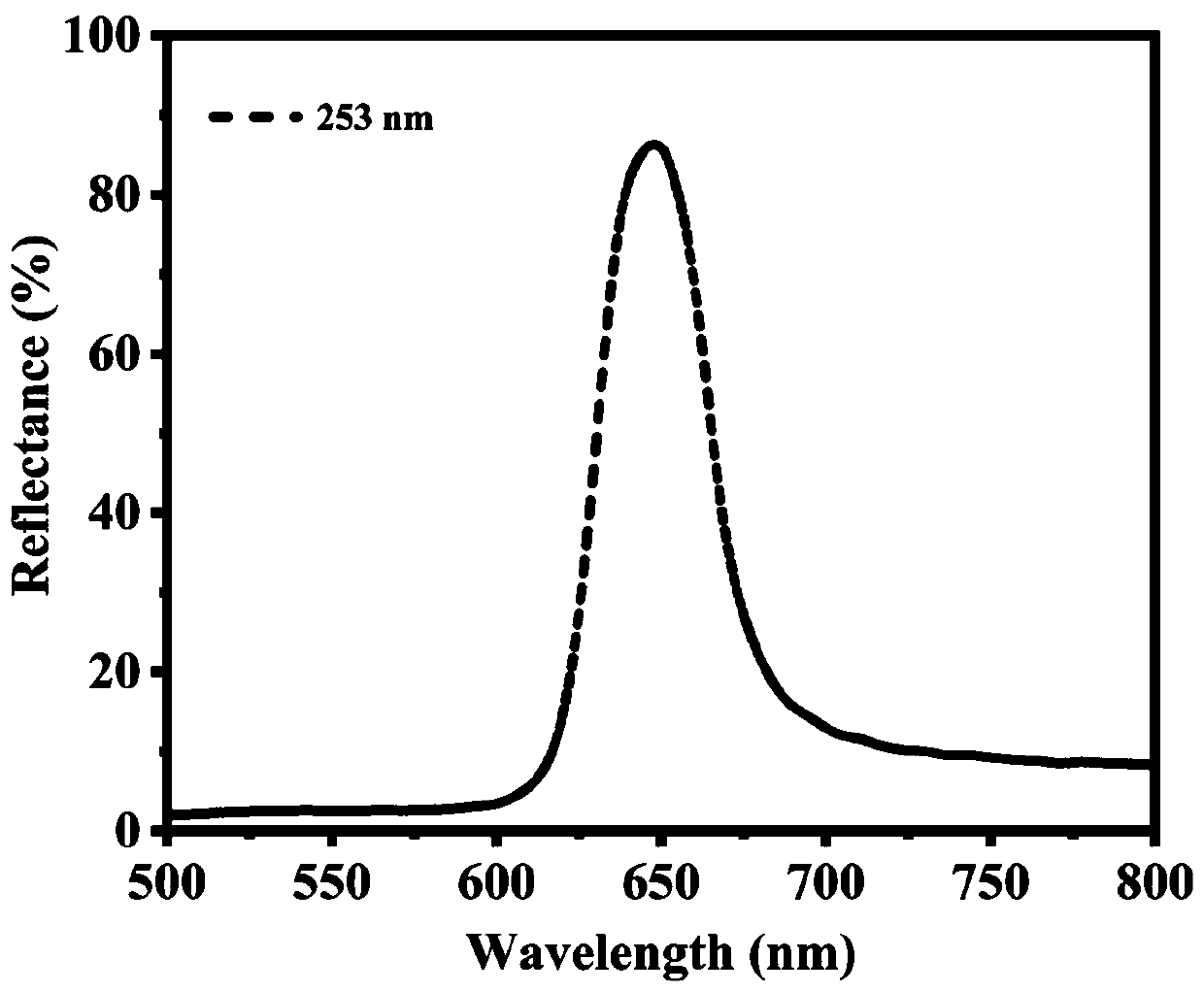

A nanostructure and soft material technology, applied in the direction of nanotechnology, can solve the problem of few applications of hydrogel interfaces, and achieve the effects of high absorption reflection ability, high reflection and absorption ability, and high reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

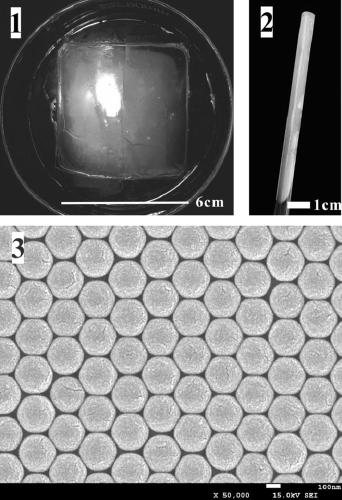

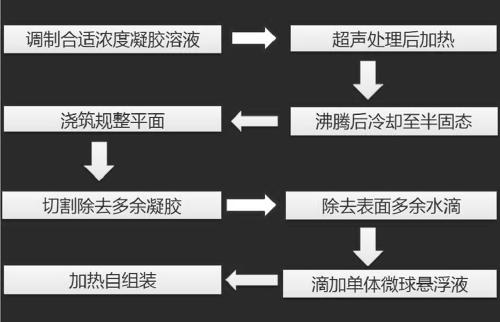

[0041] A method for assembling periodic nanostructures on a plane or a curved surface by using a soft matter interface, which realizes the rapid and low-cost preparation of large-area periodic nanostructure materials with high reflectivity and absorption reflection capability, comprising the following steps:

[0042] 1) Use water or water / PEG mixed solution as a solvent to prepare an aqueous gel solution with a suitable concentration (0.2-2% concentration, preferably, the concentration value is 1%), and then sonicate until the gel monomer (such as agarose) is completely Dissolution; where water is used as a solvent to match the polarity and ionic strength of the solvent in the colloidal suspension of assembled microspheres; ultrasonic treatment can completely dissolve the solid gel monomer (such as agarose) into water;

[0043]2) Take the result of step 1) and heat it to boiling, then slowly cool it to a semi-solid state, pour it on the target surface (flat or curved surface), ...

Embodiment 2

[0048] This embodiment is further optimized on the basis of the above-mentioned embodiments, and the same parts as the aforementioned technical solutions will not be repeated here. Further, in order to better realize the present invention, the following setting method is adopted in particular: the water / PEG mixing The solution was obtained by mixing water and PEG and stirring well.

Embodiment 3

[0050] This embodiment is further optimized on the basis of any of the above-mentioned embodiments, and the same parts as the aforementioned technical solutions will not be repeated here. Further, in order to better realize the present invention, the following setting method is adopted in particular: the PEG selection The molecular weight range of the PEG is 100~1000; the preferred molecular weight of the PEG is 200.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com