Anti-corrosion compound copper-based microwire and preparation method thereof

A micro-wire, corrosion-resistant technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of unspecified composition of metal materials, difficulty in large-scale, large-area preparation, high cost and inconvenience of graphene, etc., to reduce tissue defects , Reduced breakage rate, good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Corrosion-resistant composite copper-based fine wires, the structure of which is figure 1 As shown, it is divided into alloy layer 1 and graphene coating 2, wherein graphene coating 2 is located on the surface of alloy layer 1, and its thickness is between 0.03 μm and 0.05 μm; the copper-based alloy layer is covered by graphene coating Inside, the alloy composition is one of copper, silver, and a rare earth element selected from one of lanthanum, cerium, or yttrium, and its diameter is less than 5mm.

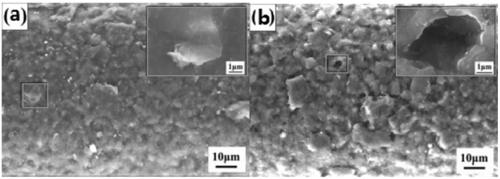

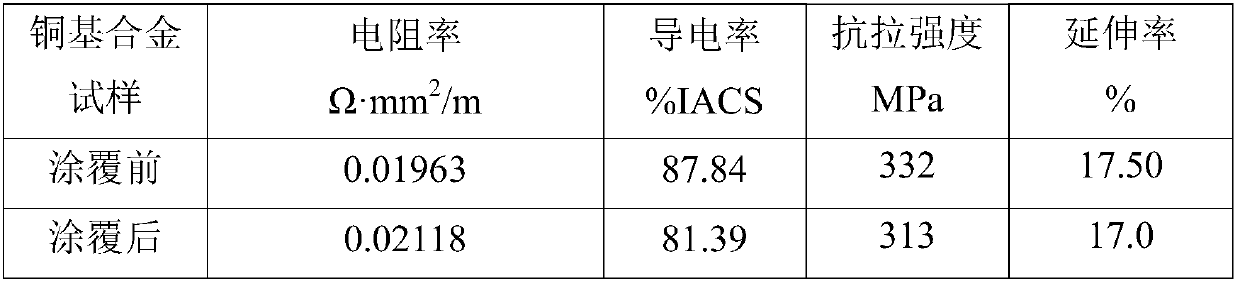

[0042] To simulate the seawater environment, the graphene-coated copper-based microwires were immersed in a 5% sodium chloride solution for 100 hours, and the changes before and after surface corrosion were compared. Scanning electron microscope was used for observation and comparison, and graphene water-based acrylic anti-corrosion coating was used for coating. The surface of alloy fine wires was rough, such as figure 2 As shown in (a), it shows that the coating covera...

Embodiment 2

[0047] The preparation method of the corrosion-resistant composite copper-based fine wire adopts standard cathode copper powder, silver powder, and an element in rare earth, and the rare earth element can be one of lanthanum, cerium or yttrium, according to the mass ratio of 5000:100:1, Fully mixed, using a horizontal continuous directional solidification furnace to prepare a copper-based alloy rod with a diameter of 10mm, and then cold drawing through rough drawing, fine drawing and micro drawing, the drawing plan sequence is: (1) The rough drawing process starts from a diameter of 10.0mm to 2.0mm, annealed online under the state of drawing to 2.0mm, and kept at 500°C for 5 minutes; (2) The fine drawing process will make the diameter 2.0mm to 1.0mm, and the second step will draw 1.0mm to 0.5mm and 0.5mm to 0.2mm; (3) The micro-drawing process is also divided into two steps, which is to first pull 0.2mm to 0.1mm and then pull 0.1mm to 0.05mm and below. In this way, copper-base...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com