Production process of diamond saw blade

A technology of diamond saw blade and production process, which is applied in the direction of metal sawing equipment, metal processing equipment, sawing machine tool manufacturing, etc., can solve the problems of high cost of pure metal powder, low welding strength, cracking and deformation of cutting blades, etc., to achieve Improve structural hardness and thermal stability, improve structural strength and wear resistance, and reduce the effect of bubble diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

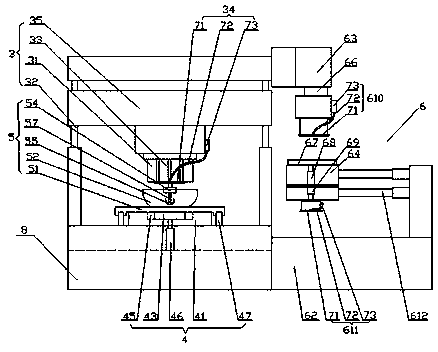

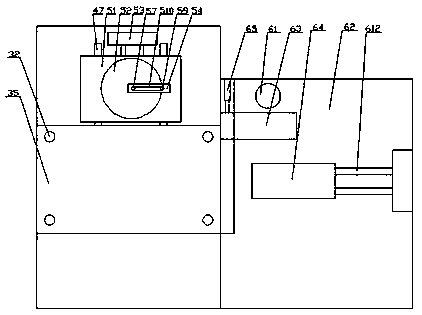

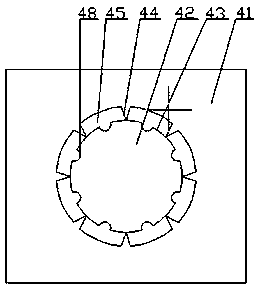

[0041] An embodiment of the production process of a diamond saw blade in the present invention, the diamond saw blade includes a base body 1 and a plurality of diamond blades 2, and the plurality of diamond blades 2 are evenly distributed on the outer edge of the base body 1 to form a disc-shaped structure;

[0042] A. Ingredients: by weight fraction, diamond powder 15-20 parts, copper powder 20-25 parts, iron powder 30-40 parts, manganese powder 20-25 parts, nickel powder 4-5 parts, glass fiber powder 20-30 parts 10-20 parts of ceramic powder, 3-5 parts of iron oxide powder, 6-8 parts of zinc oxide powder, 2-4 parts of pore-forming powder;

[0043] B. Mixing and cold pressing: Mix the above-mentioned raw materials, and stir and mix the above-mentioned ingredients through the stirring blade 55 of the special cold press. The speed is 400r / min-480r / min, and the ingredients are pressed on the outer edge of the substrate 1 to form a workpiece a. The pressing pressure is 200KN-280K...

Embodiment 1

[0048] Specifically include the following steps:

[0049] A. Ingredients: by weight fraction, 15 parts of diamond powder, 20 parts of copper powder, 30 parts of iron powder, 20 parts of manganese powder, 4 parts of nickel powder, 20 parts of glass fiber powder, 10 parts of ceramic powder, 3 parts of iron oxide powder , 6 parts of zinc oxide powder, 2 parts of pore-forming powder;

[0050] B. Mixing and cold pressing: Mix the above-mentioned raw materials, and stir and mix the above-mentioned ingredients through the stirring blade 55 of the special cold press. The speed is 400r / min, and the ingredients are pressed on the outer edge of the substrate 1 to form a workpiece a, and the pressing pressure is 200KN, so that the center of the diamond cutter head 2 of the workpiece a protrudes toward the substrate 1 to form a raised portion 22;

[0051] C. Sintering: Set the plurality of workpieces a obtained in step B on the mold, and add graphite gaskets between two adjacent workpiece...

Embodiment 2

[0055] Specifically include the following steps:

[0056] A. Ingredients: by weight fraction, 20 parts of diamond powder, 25 parts of copper powder, 40 parts of iron powder, 25 parts of manganese powder, 5 parts of nickel powder, 30 parts of glass fiber powder, 20 parts of ceramic powder, 5 parts of iron oxide powder , 8 parts of zinc oxide powder, 4 parts of pore-forming powder;

[0057] B. Mixing and cold pressing: Mix the above-mentioned raw materials, and stir and mix the above-mentioned ingredients through the stirring blade 55 of the special cold press. The speed is 480r / min, and the ingredients are pressed on the outer edge of the substrate 1 to form a workpiece a, and the pressing pressure is 280KN, so that the center of the diamond cutter head 2 of the workpiece a protrudes toward the substrate 1 to form a raised portion 22;

[0058] C. Sintering: Set the plurality of workpieces a obtained in step B on the mold, and add graphite gaskets between two adjacent workpiece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com