Method for purifying salt-containing wastewater in waste incineration fly ash process

A technology for waste incineration fly ash and salty wastewater, applied in chemical instruments and methods, descaling and water softening, water/sewage treatment, etc., can solve problems such as affecting production efficiency, small crystallizer, large evaporator, etc. , to achieve the effect of inhibiting corrosion, reducing operating costs, and sufficient elastic margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for purifying saline waste water from waste incineration fly ash process, the specific scheme is as follows:

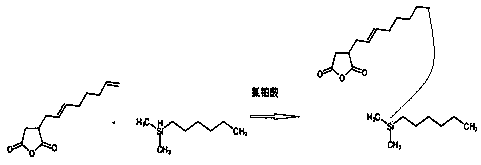

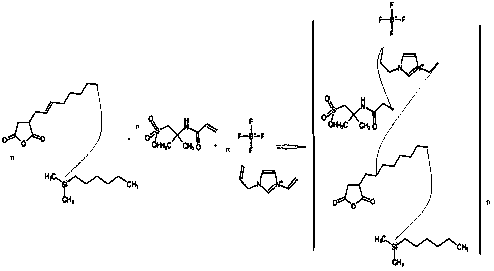

[0027] Pass the brine into the aeration tank with carbon dioxide, adjust the pH value of the brine to 8, then add 0.1% liquid caustic soda, then preheat the brine to 60°C, add 0.05% scale inhibitor, and then preheat the brine The heated brine is pumped into the forced circulation evaporator, and the compressed secondary steam is used to heat it, and the solution begins to evaporate and concentrate; after the evaporation reaches 50%, it is transferred to the secondary falling film evaporator, and the compressed secondary steam is used again. The steam heats the solution, and the solution continues to evaporate and concentrate to 22%; the evaporation temperature of the first-stage forced circulation evaporation concentration part is 86°C; the effective temperature difference is 6°C; the vacuum degree is 0.08MPa; the second-stage falling film evaporation c...

Embodiment 2

[0037] A method for purifying saline waste water from waste incineration fly ash process, the specific scheme is as follows:

[0038]Pass the brine into the aeration tank with carbon dioxide, adjust the pH value of the brine to 9, then add 0.3% liquid caustic soda, then preheat the brine to 70°C, add 0.07% scale inhibitor, and then preheat the brine The heated brine is pumped into the forced circulation evaporator, and the compressed secondary steam is used to heat it, and the solution begins to evaporate and concentrate; after evaporating to 55%, it is transferred to the secondary falling film evaporator, and the compressed secondary steam is used again. The steam heats the solution, and the solution continues to evaporate and concentrate to 26%; the evaporation temperature of the first-stage forced circulation evaporation concentration part is 91°C; the effective temperature difference is 8°C; the vacuum degree is 0.09MPa; the second-stage falling film evaporation crystalliza...

Embodiment 3

[0048] A method for purifying saline waste water from waste incineration fly ash process, the specific scheme is as follows:

[0049] Pass the brine into the aeration tank with carbon dioxide, adjust the pH value of the brine to 10, then add 0.5% liquid caustic soda, then preheat the brine to 80°C, add 0.08% scale inhibitor, and then preheat the brine The heated brine is pumped into the forced circulation evaporator, and the compressed secondary steam is used to heat it, and the solution begins to evaporate and concentrate; after evaporating to 65%, it is transferred to the secondary falling film evaporator, and the compressed secondary steam is used again. The steam heats the solution, and the solution continues to evaporate and concentrate to 29%; the evaporation temperature of the first-stage forced circulation evaporation concentration part is 94°C; the effective temperature difference is 12°C; the vacuum degree is 0.1MPa; the second-stage falling film evaporation crystalli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com