An improved low liquid limit silt roadbed material and its preparation method and application

A technology of low liquid limit and soil roadbed, applied in roads, roads, buildings, etc., can solve the problems of low mechanical properties, high improvement cost, poor water stability, etc., achieve good impermeability, reduce engineering costs, and cheap prices Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

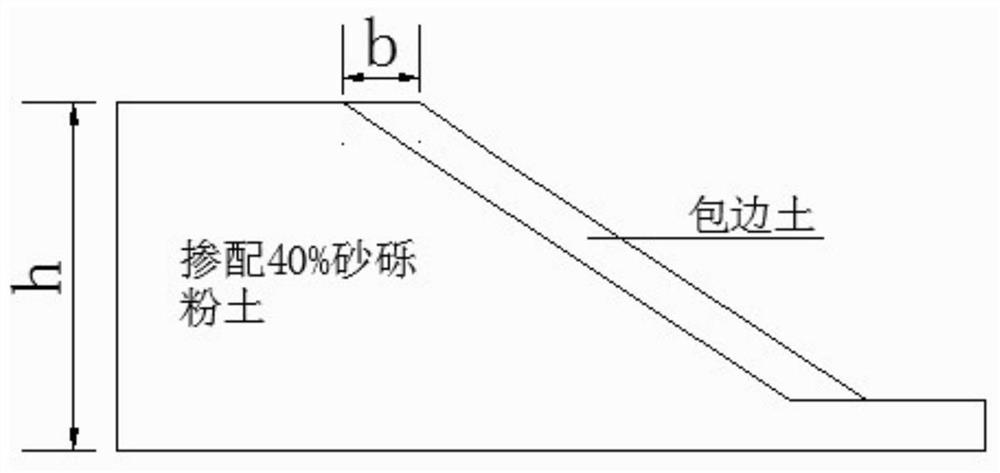

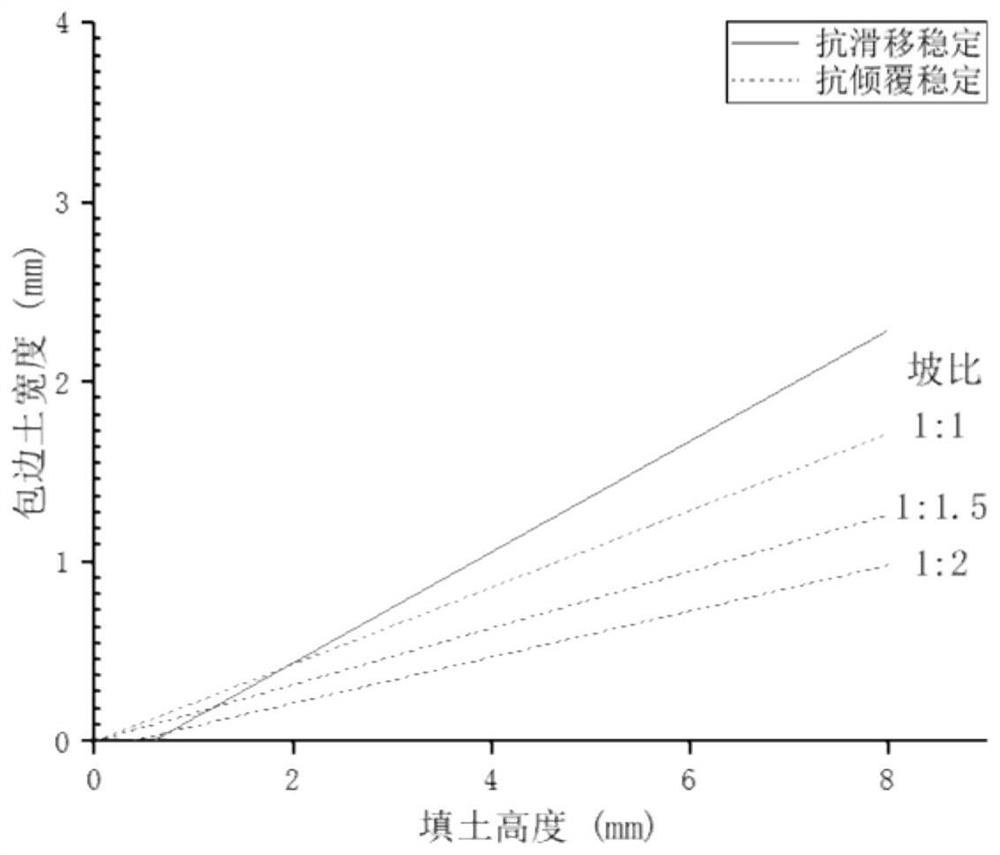

Method used

Image

Examples

Embodiment 1

[0047] The prepared alkali excitation material is blended into low liquid limit silt according to a blending ratio of 3%, and an appropriate amount of water is added to prepare the edge wrapping material with a moisture content of 10.5% to 12.5%.

[0048] The preparation process in the alkali-activated material is as follows: mix fly ash, steel slag and cement according to the mass ratio of 2:2:1, then mix with water of equal quality to make A liquid and stir evenly, and the concentration is 5mol / L NaOH is set as liquid B, and liquid A and liquid B are mixed at a volume ratio of 3:1 to make an alkali-activated material.

Embodiment 2

[0050] The prepared alkali excitation material is blended into low liquid limit silt according to a blending ratio of 5%, and an appropriate amount of water is added to prepare the edge wrapping material with a moisture content of 11.2% to 13.2%.

[0051] The preparation process in the alkali-activated material is as follows: mix fly ash, steel slag and cement according to the mass ratio of 2:2:1, then mix with water of equal quality to make A liquid and stir evenly, and the concentration is 5mol / L NaOH is set as liquid B, and liquid A and liquid B are mixed at a volume ratio of 3:1 to make an alkali-activated material.

Embodiment 3

[0053] The prepared alkali-activated material is blended into low-liquid-limit silt at a blending ratio of 8%, and an appropriate amount of water is added to make an edge-wrapping material with an optimum water content of 12.1%-14.1%.

[0054] The preparation process in the alkali-activated material is as follows: mix fly ash, steel slag and cement according to the mass ratio of 2:2:1, then mix with water of equal quality to make A liquid and stir evenly, and the concentration is 5mol / L NaOH is set as liquid B, and liquid A and liquid B are mixed at a volume ratio of 3:1 to make an alkali-activated material.

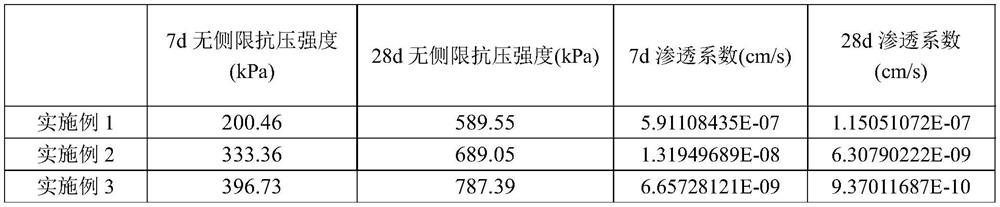

[0055] Put the subgrade edging materials prepared in Examples 1 to 3 into the curing room for standard curing (temperature 20±2°C, relative humidity ≥ 95%), and test their unconfined compressive strength and penetration at 7d and 28d coefficient.

[0056] The test results are shown in Table 1 below:

[0057] The performance parameter test of table 1 embodiment 1-3

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com