Preparation method of carbonized loofah/graphene-carbon nanotube composite material

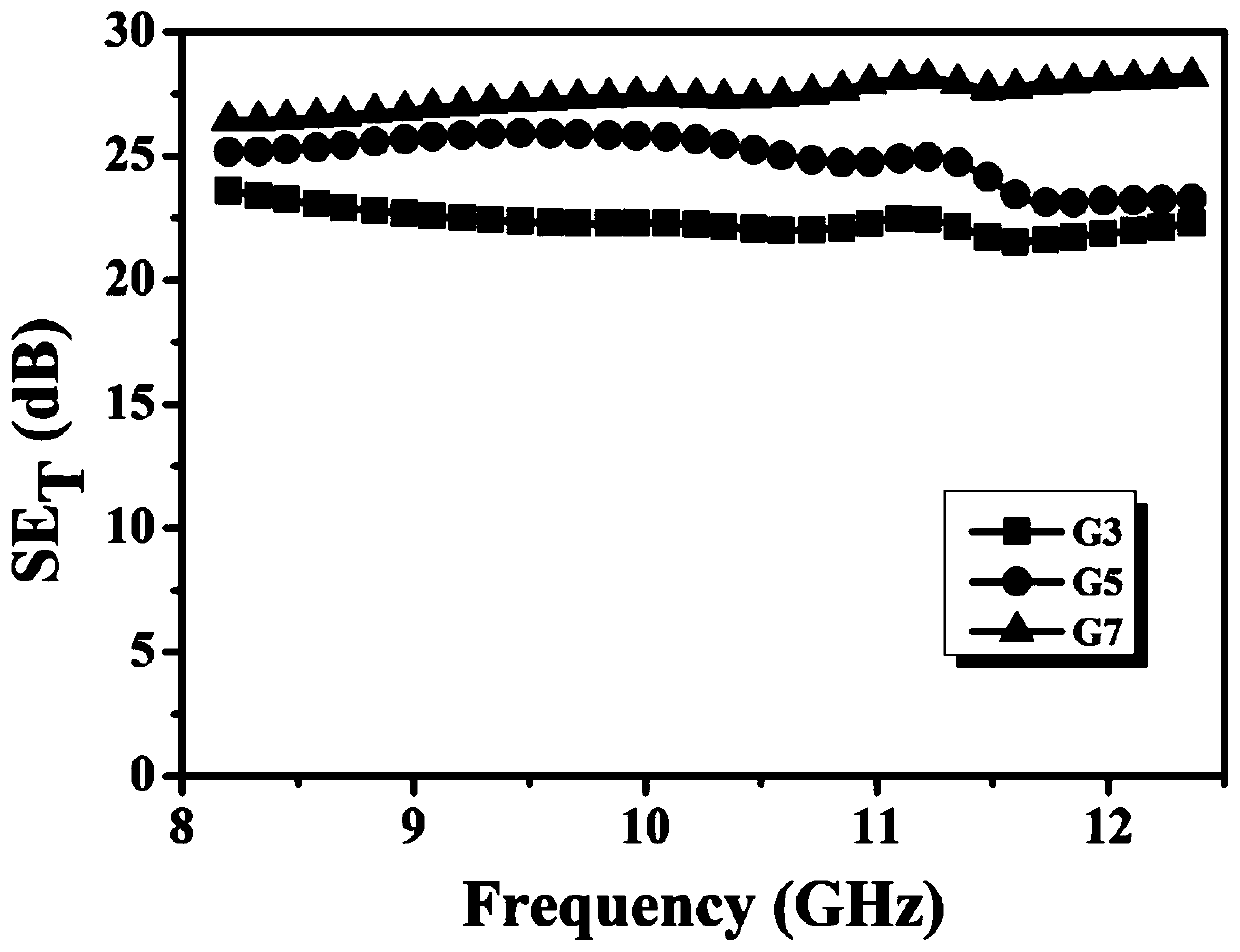

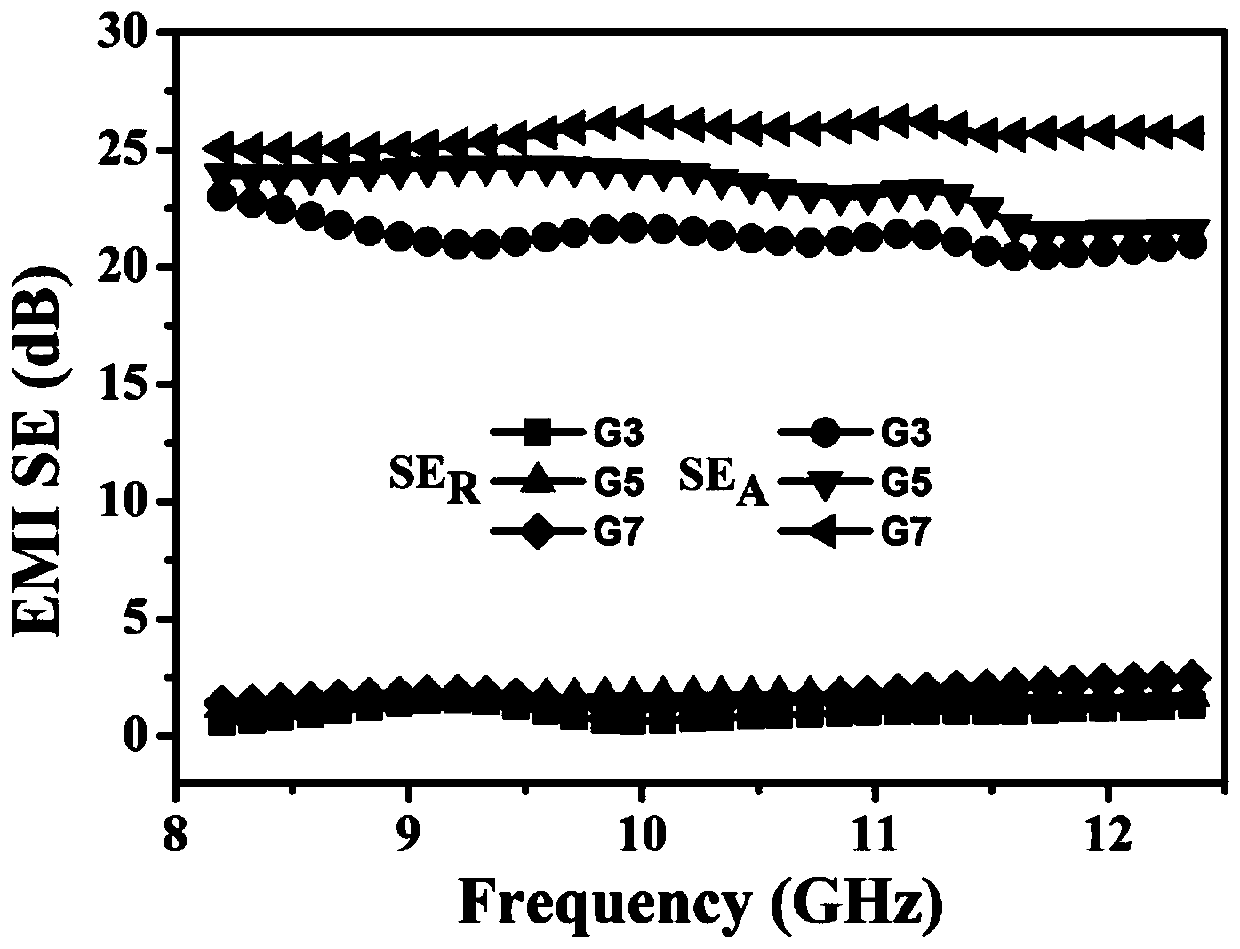

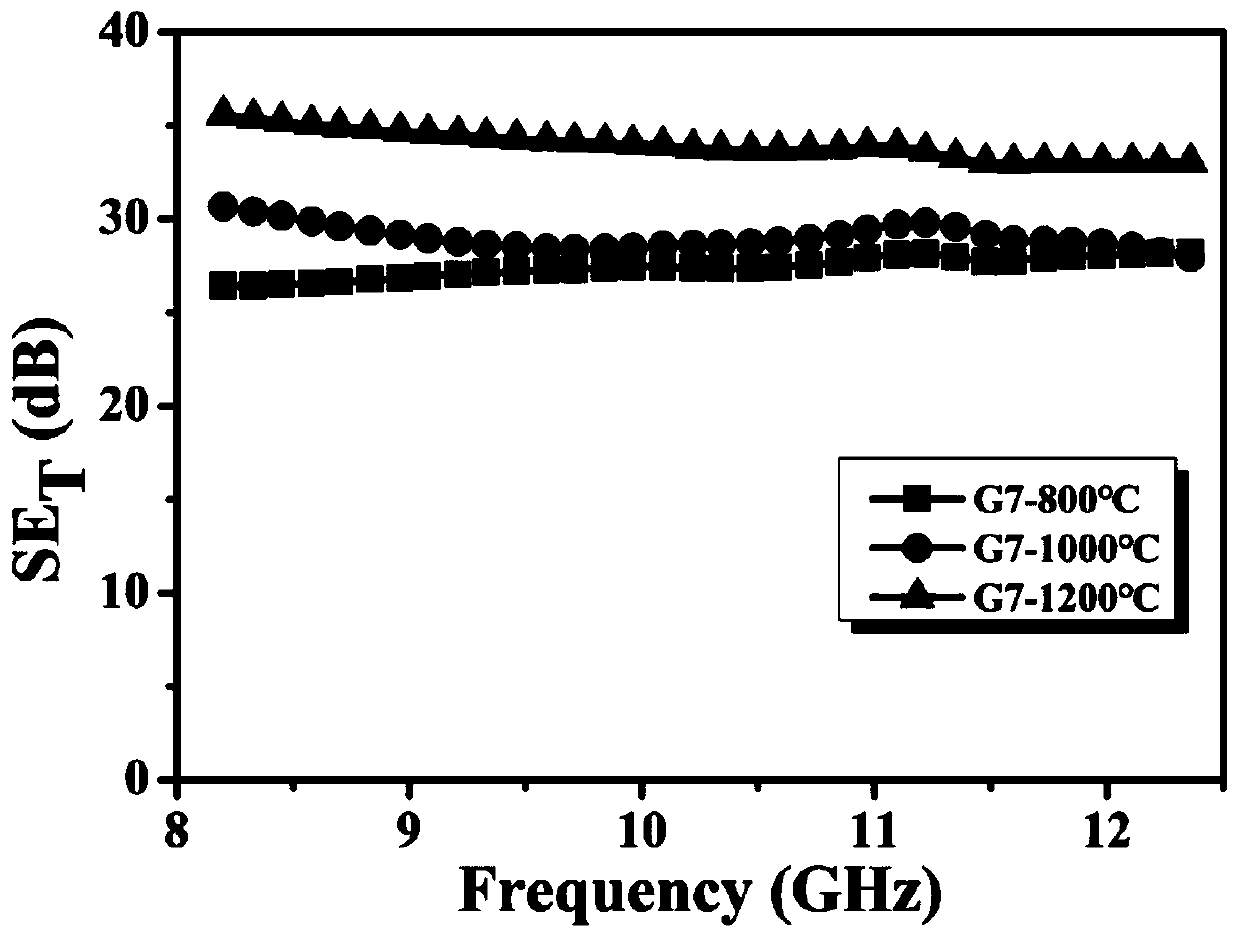

A carbon nanotube and composite material technology, which is applied in the field of preparation of carbonized loofah/graphene-carbon nanotube composite materials, can solve the problems of low electromagnetic shielding performance of composite materials, and achieves easy mass production, low production cost, high The effect of electromagnetic shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A kind of preparation method of carbonized loofah / graphene-carbon nanotube (CL / GNSs-CNT / CE) composite material of the present invention, concrete steps are as follows:

[0026] Step 1, dissolving polyvinyl alcohol particles in deionized water and reacting in a water bath at 90°C for 1-2 hours to obtain a polyvinyl alcohol solution with a mass concentration of 80 mg / mL;

[0027] Step 2, dispersing graphene and carbon nanotubes in a polyvinyl alcohol solution, and ultrasonically stirring for 30 to 60 minutes to obtain a graphene-carbon nanotube / polyvinyl alcohol solution;

[0028] The mass ratio of graphene, carbon nanotubes and polyvinyl alcohol solution is 0.025-0.062:0.008:10;

[0029] The producers of graphene are Xiamen Knano Graphene Company; the producers of carbon nanotubes are Nanocyl S.A.Nanocyl NC7000 of Belgium.

[0030] The thickness of graphene is <30nm; the average diameter of carbon nanotubes is 9.5nm;

[0031] Step 3, preparing carbonized loofah / graphen...

Embodiment 1

[0040] A kind of preparation method of CL / GNSs-CNT / CE composite material, concrete steps are as follows:

[0041] Step 1: Dissolve 8g of polyvinyl alcohol particles in 92ml of deionized water and react in a water bath at 90°C for 1 hour to obtain a polyvinyl alcohol solution with a mass concentration of 80mg / mL;

[0042] Step 2, disperse 3wt% graphene and 1wt% carbon nanotubes in 10ml of the above-mentioned polyvinyl alcohol solution, and ultrasonically stir for 30min to 60min to obtain a graphene-carbon nanotube / polyvinyl alcohol solution;

[0043] Step 3, preparing CL / GNSs-CNT composite material, the specific steps are as follows:

[0044] Step 3.1, wash the loofah, cut out a rectangle with a size of 40×30mm, place it in a vacuum oven at 60°C for drying, and pour the graphene-carbon nanotube / polyvinyl alcohol solution on the loofah, so that the solution is evenly wrapped in the On the loofah fiber, place it in a 60°C vacuum oven for drying and then compact it;

[0045] Ste...

Embodiment 2

[0050] A kind of preparation method of CL / GNSs-CNT / CE composite material, concrete steps are as follows:

[0051] Step 1: Dissolve 8g of polyvinyl alcohol particles in 92ml of deionized water and react in a water bath at 90°C for 1-2 hours to obtain a polyvinyl alcohol solution with a mass concentration of 80mg / ml;

[0052] Step 2, disperse 5wt% graphene and 1wt% carbon nanotubes in the above-mentioned polyvinyl alcohol solution of 10ml, and ultrasonically stir for 40min to obtain a graphene-carbon nanotube / polyvinyl alcohol solution;

[0053] Step 3, preparing CL / GNSs-CNT composite material, the specific steps are as follows:

[0054] Step 3.1, wash the loofah, cut out a rectangle with a size of 40×30mm, place it in a vacuum oven at 60°C for drying, and pour the graphene-carbon nanotube / polyvinyl alcohol solution on the loofah, so that the solution is evenly wrapped in the On the loofah fiber, place it in a 60°C vacuum oven for drying and then compact it;

[0055] Step 3.2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com