Method for growing large-area single crystal 3R-MoS2 film by using molten salt electrolysis method

A 3r-mos2, molten salt electrolysis technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve problems such as small resistivity change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

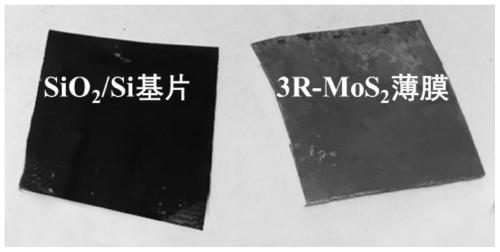

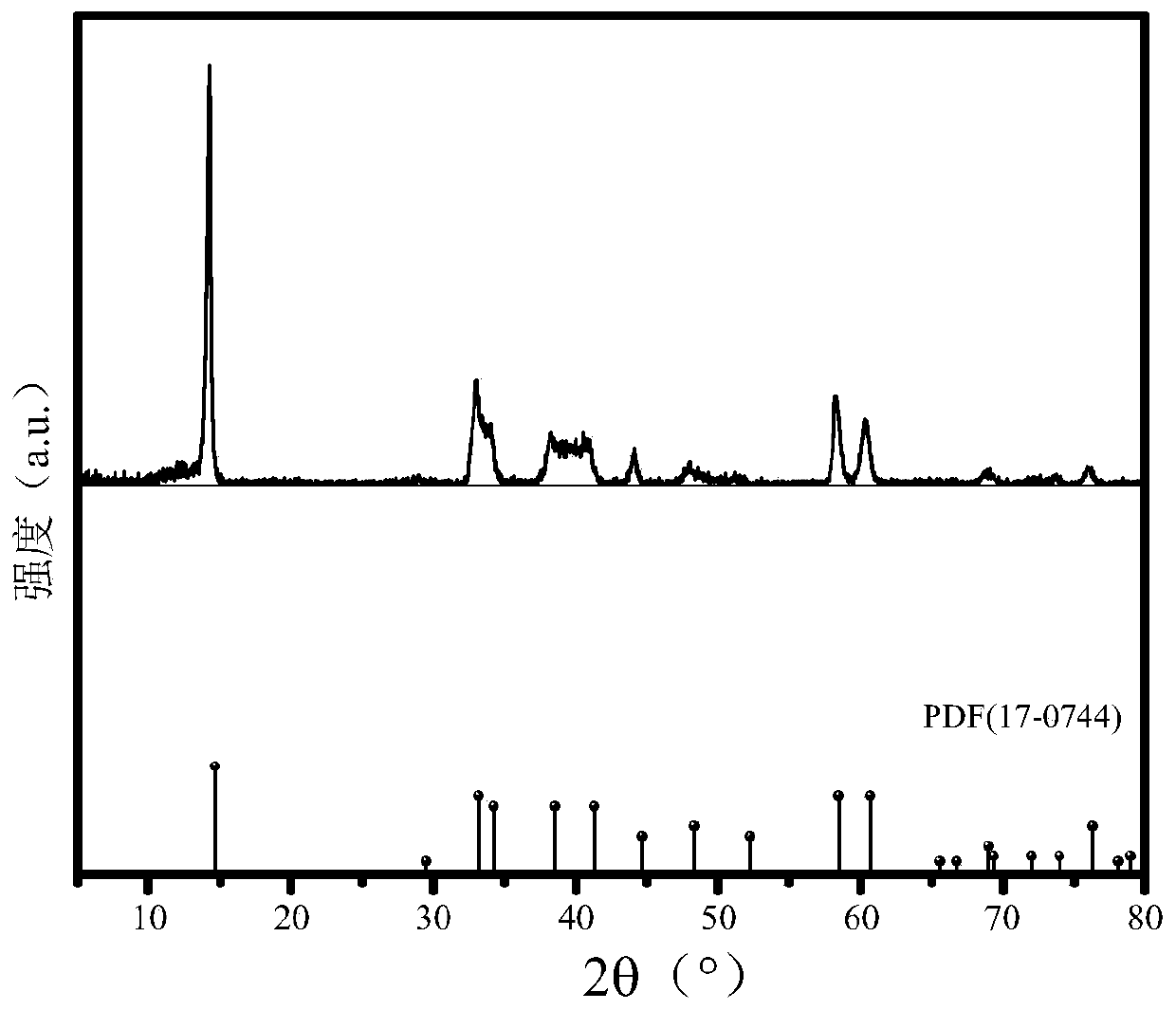

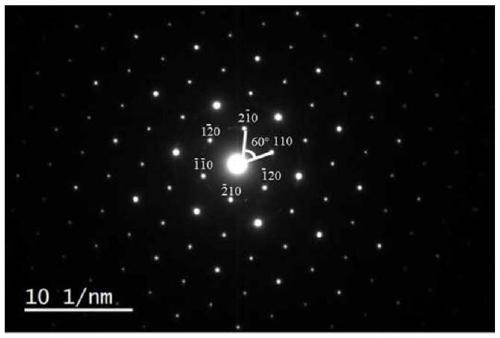

[0022] Specific implementation mode 1: In this implementation mode, large-area single crystal 3R-MoS is grown by molten salt electrolysis 2 Thin film method, proceed as follows:

[0023] 1. According to the mass ratio of KCl, NaCl, sulfur salts and molybdenum salts (26-29): (37-40): (6-5): (4-3) KCl, NaCl, sulfur salts and Molybdenum salt is added to the electrolytic cell of the electrolytic furnace, heated and melted to obtain an electrolyte system of KCl-NaCl-sulfur salt-molybdenum salt;

[0024] 2. Grind the substrate with 500-2000 mesh sandpaper and then polish it, and then use acetone and absolute ethanol to clean it ultrasonically to ensure that the surface of the substrate is clean and free of grease and pollutants; after drying, place the growth side of the substrate upward into the electrolytic tank;

[0025] 3. Using metal molybdenum wire as the working electrode and auxiliary electrode, the electrolysis temperature is 657-850°C and the current is 0.5-1.0Acm -2 Un...

specific Embodiment approach 2

[0026] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the sulfur salt described in step 1 is KSCN or K 2 S. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the molybdenum salt described in step one is Na 2 MoO 4 or MoO 3 . Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com