Lithium ion battery negative electrode active material, preparation method thereof and lithium ion battery

A negative electrode active material and lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor electronic conduction, material volume expansion, volume expansion, etc., and achieve small difference between charge and discharge platforms, high initial Effects of Coulombic efficiency and proper working potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention provides a method for preparing a lithium-ion battery negative electrode active material described in any one of the above technical solutions, comprising:

[0044] It is obtained by mixing copper powder, germanium powder and phosphorus powder according to the stoichiometric ratio of the chemical formula, and ball milling under the condition of inert gas.

[0045] In the present invention, copper powder, germanium powder and phosphor powder are firstly mixed according to the metering ratio of the chemical formula, and the mixing ratio is the metering ratio of the above chemical formula. The sources of the above copper powder, germanium powder and phosphor powder are not limited and can be purchased commercially.

[0046] Then fill the inert gas as a protective gas to isolate the air to prevent the material from reacting with oxygen or other substances in the air during the ball milling process. Then set the ball milling parameters in the high-energ...

Embodiment 1

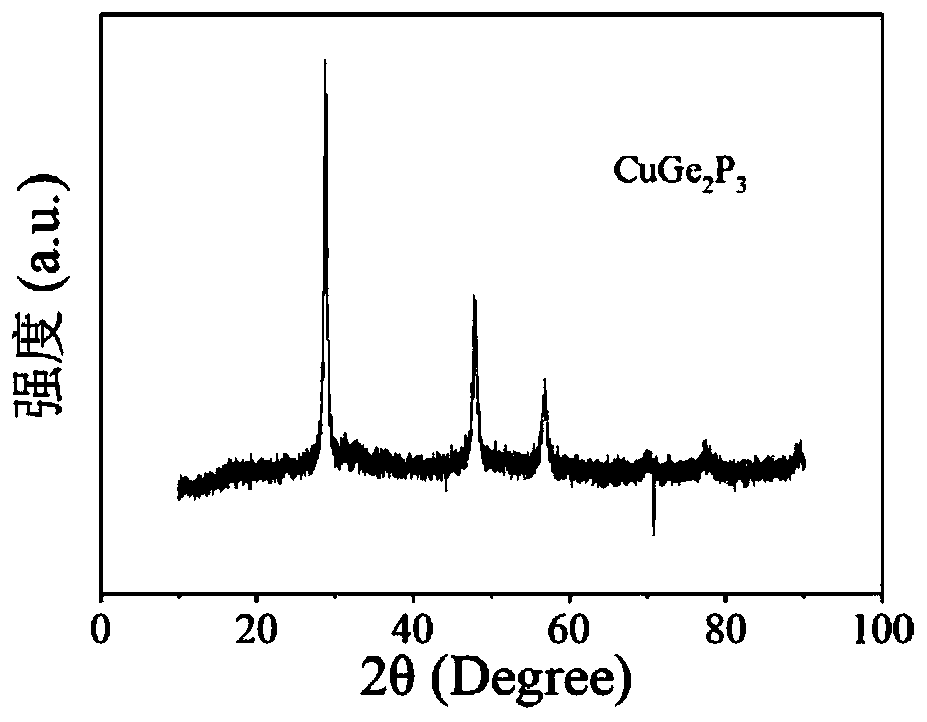

[0060] According to the stoichiometric ratio (molar ratio) of the chemical formula of the desired synthetic substance (CuGe 2 P 3 ), M Cu =63.546, M Ge =72.63, M P = 30.973. Stoichiometric ratio Cu:Ge:P=1:2:3; Material collection: 3g of material is taken in total, that is, 0.6318g of Cu powder, 1.4443g of Ge powder, and 0.9239g of P powder are put into the ball mill tank, and then 25 stainless steel ball mills are added Beads, ensure that the ratio of ball to material is 20:1, and then fill with inert gas as a protective gas to isolate the air and prevent the material from reacting with oxygen or other substances in the air during the ball milling process. Then set the ball milling parameters in the high-energy ball mill (every ball milling 1h interval 25min, the speed is 1200r, the total ball milling time 6h, one-way ball milling), and then take the material under the atmosphere of inert gas, and take the material to measure XRD, XRD The result is as figure 1 .

Embodiment 2

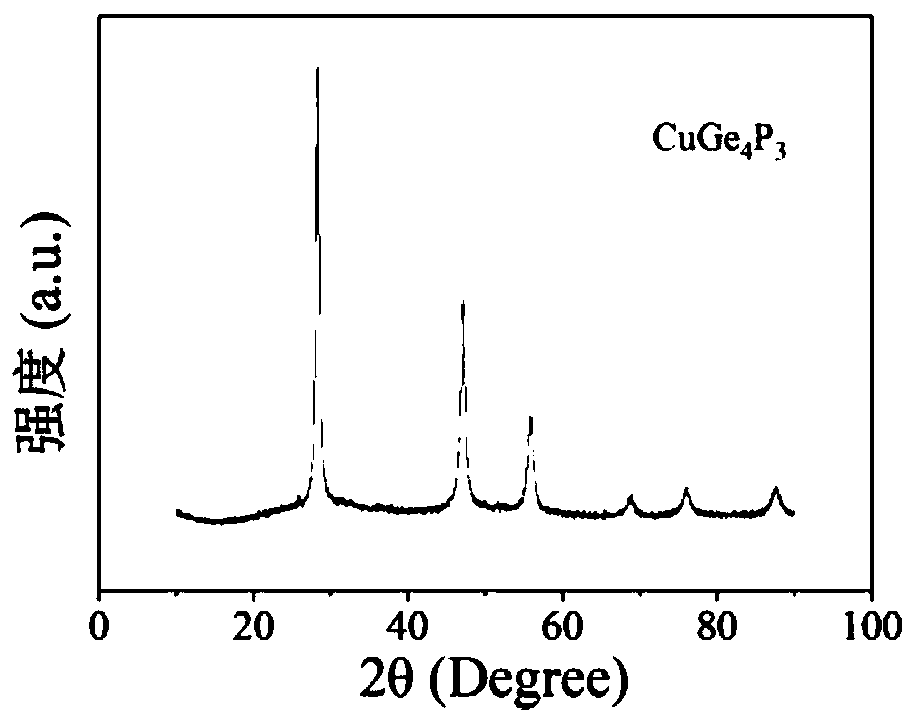

[0062] According to the stoichiometric ratio (molar ratio) of the chemical formula of the desired synthetic substance (CuGe 4 P 3 ), take 0.4264g of Cu powder, 1.9499g of Ge powder, and 0.6237g of P powder and put them into the ball mill tank to ensure that the ball-to-material ratio is 20:1, and then fill in an inert gas as a protective gas to isolate the air, so as to prevent the material from contacting the oxygen in the air during the ball milling process. or react with other substances. Then set the ball milling parameters in the high-energy ball mill (every ball milling 1h interval 25min, rotating speed 1200r, total ball milling time 10h, one-way ball milling), and then take the material under the atmosphere of inert gas, take the material and measure the XRD, XRD The result is as figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com