High-dielectric-constant microwave ferrite material, preparation method and microwave communication device

A ferrite material, high dielectric constant technology, applied in the direction of magnetic materials, electrical components, inorganic material magnetism, etc., can solve the problems of high pre-burning temperature, unfavorable production and environmental protection, etc., to improve the dielectric constant and reduce production. Cost, effect of reducing burn-in temperature and sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

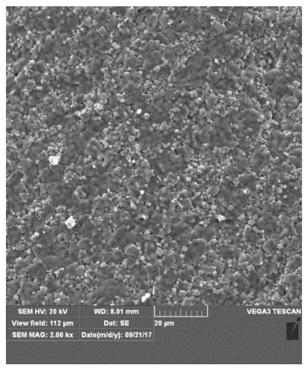

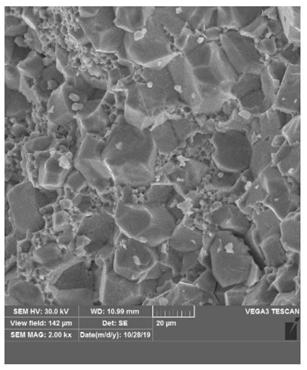

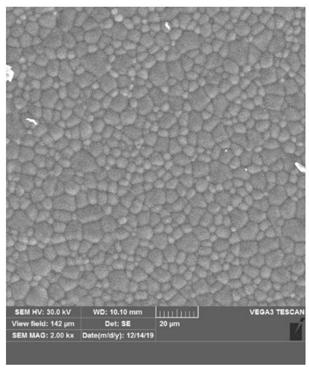

Image

Examples

preparation example Construction

[0048] The preparation method of the high dielectric constant microwave ferrite material of a specific embodiment comprises the following steps:

[0049] 1) According to the molecular formula Bi 1.25 Ca 0.25+2x Y 1.5-2x Zr 0.25 Al x mn y f e4.75-x-y , 0.05≤x≤0.3, 0.05≤y≤0.15. The stoichiometric ratio, calculate the ratio of the required raw materials, weigh the raw materials, the corresponding raw materials are respectively Bi 2 o 3 , CaCO 3 , Y 2 o 3 , ZrO 2 、Al 2 o 3 , Mn 3 o 4 , Fe 2 o 3 . Preferably, the raw materials are all analytically pure, and the Al 2 o 3 and ZrO 2 All are in the nanoscale, and the D50 is 100nm to 200nm.

[0050] 2) Wet ball mill mixing: Put the raw materials weighed in step 1) into the ball mill, add the corresponding zirconium balls and pure water according to the ratio of raw materials: zirconium balls: pure water = 1:2:1.5, and mix evenly at a speed of 200rpm for 4 hours Finally, the discharge is sieved to obtain mixed oxid...

Embodiment 1

[0058] According to molecular formula Bi 1.25 Ca 0.35 Y 1.4 Zr 0.25 Al 0.05 mn 0.05 f e4.65 The stoichiometric ratio, calculate the ratio of the required raw materials, weigh the raw materials, wherein the corresponding raw materials are respectively Bi 2 o 3 , CaCO 3 , Y 2 o 3 , ZrO 2 、Al 2 o 3 , Mn 3 o 4 , Fe 2 o 3 , followed by wet ball milling, drying and sieving, 900°C heat preservation for 5 hours, pre-calcination, wet ball milling, spray granulation, compression molding, and finally sintering at 1080°C and heat preservation for 5 hours to obtain microwave ferrite materials. After testing, the characteristics of the microwave ferrite material: the sintered density is 5.97g / cm 3 , ε=27.8, 4πMs=1950Gs, ΔH=45Oe, Tc=202°C.

Embodiment 2

[0060] According to molecular formula Bi 1.25 Ca 0.45 Y 1.3 Zr 0.25 Al 0.1 mn 0.05 f e4.6The stoichiometric ratio is calculated, the ratio of the required raw materials is calculated, the raw materials are weighed, and then mixed by wet ball milling, dried and sieved, pre-fired at 800°C for 5 hours, finely ground by wet ball milling, spray granulation, compression molding, and finally in The microwave ferrite material was obtained by sintering at 1030° C. and holding for 5 hours. After testing, the characteristics of the microwave ferrite material: the sintered density is 5.96g / cm 3 , ε=28.1, 4πMs=1912Gs, ΔH=47Oe, Tc=225°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sintered density | aaaaa | aaaaa |

| Sintered density | aaaaa | aaaaa |

| Sintered density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com