Cellulose source carbon-based photothermal conversion material for sea water desalination and preparation method thereof

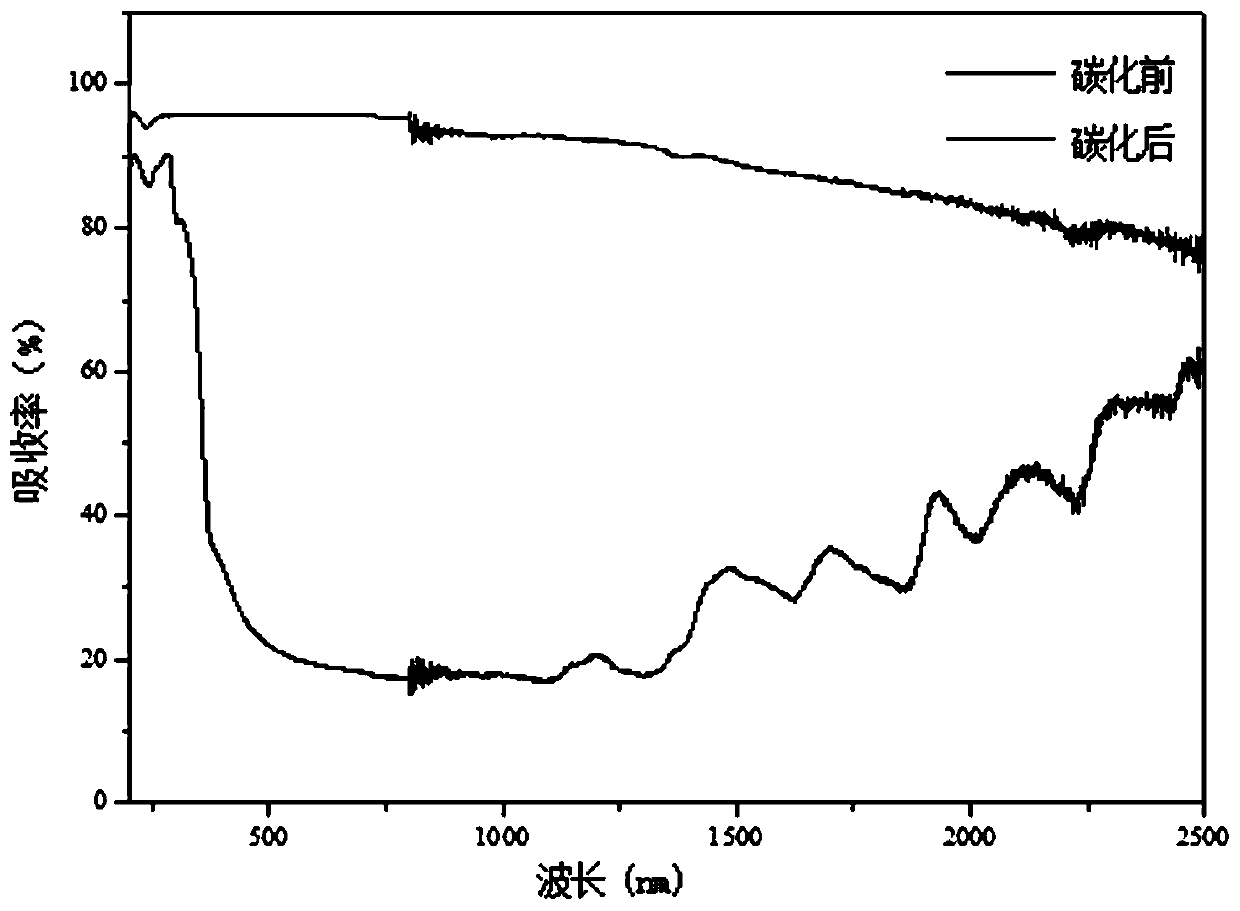

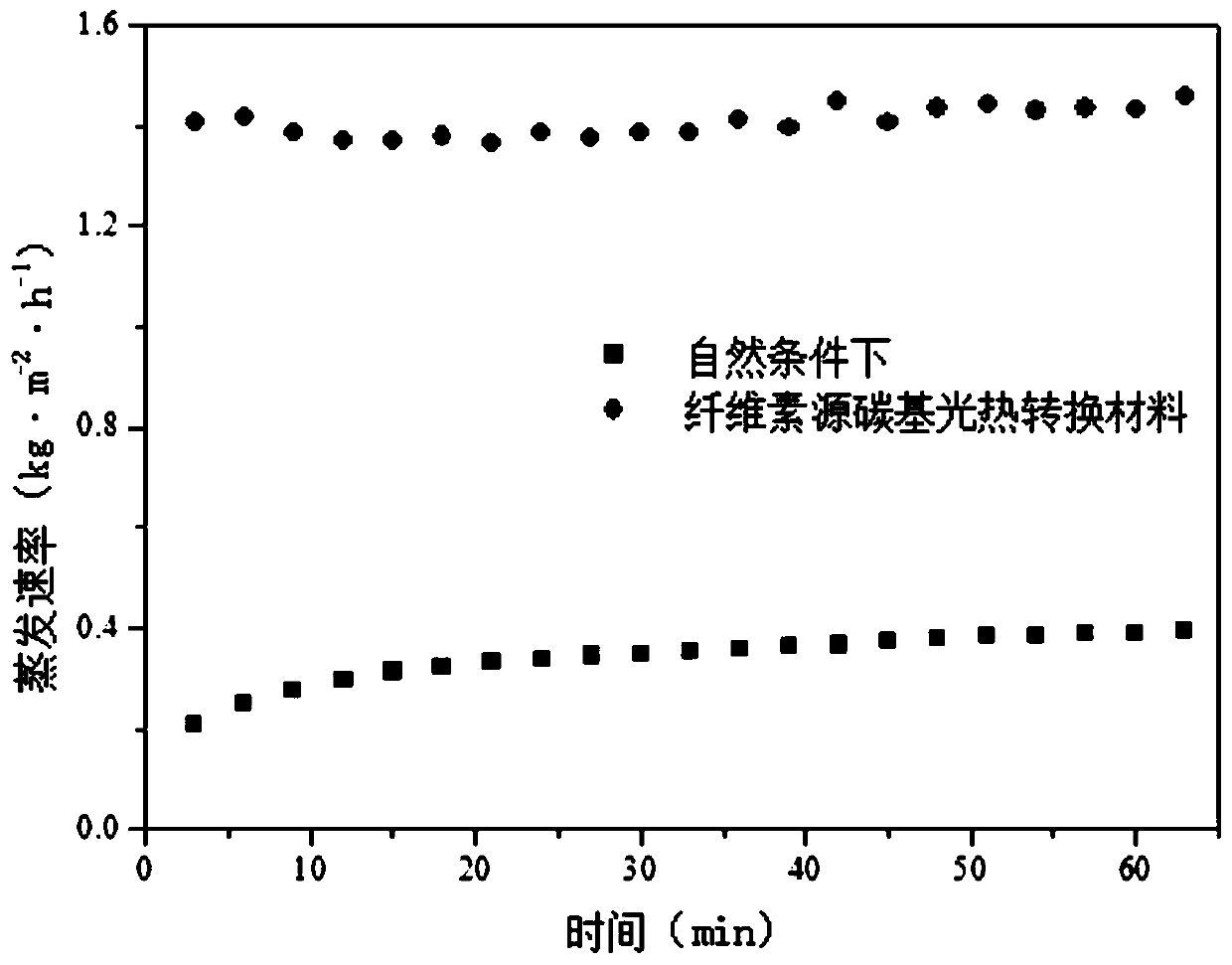

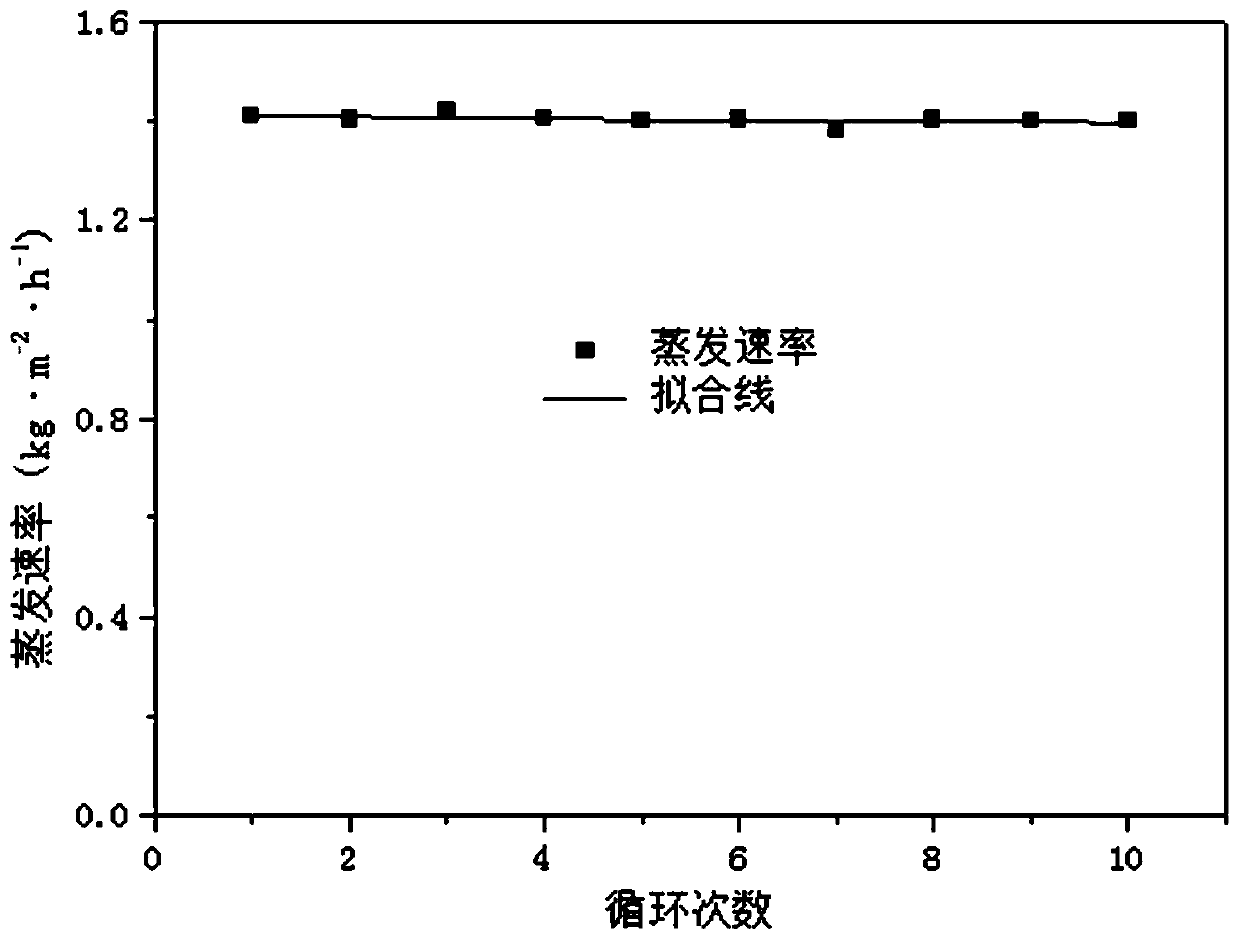

A light-to-heat conversion material and cellulose technology, applied in the field of solar desalination, can solve the problems of high cost, poor biodegradability, and uncontrollable structure, and achieve the effects of low cost, increased absorption rate, and improved conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a method for preparing a cellulose-sourced carbon-based light-to-heat conversion material for seawater desalination, comprising the following steps:

[0024] Step 1, mixing nanocellulose, cell regulator, epoxy resin, polyamide resin and water to prepare a mixed suspension; wherein, the contents of each component in the mixed suspension are: nanocellulose: 1~ 10wt%, epoxy resin: 2-10wt%, polyamide resin: 5-10wt%, cell regulator: 1-20wt% and the rest of water, the total content of the above components is 100wt%;

[0025] Step 2, place the mixed suspension in a high-speed overhead stirrer and stir until uniform, the stirring speed is 1000-2000r / min, and the stirring time is 10-30min;

[0026] Step 3. Pour the uniformly stirred mixed suspension into a custom-made container, and let it stand for degassing for 12-24 hours to obtain a homogeneous suspension. The size and shape of the custom-made container match the size and shape of the sample;

[0027]...

Embodiment 1

[0032] Example 1 provides a method for preparing a cellulose-sourced carbon-based light-to-heat conversion material for seawater desalination, comprising the following steps:

[0033] Step 1, mixing nanocellulose, cell regulator, epoxy resin, polyamide resin and water to prepare a mixed suspension; wherein, the contents of each component in the mixed suspension are: nanocellulose: 2wt% 1. Epoxy resin: 5wt%, polyamide resin: 5wt%, cell regulator: 20wt% and water: the rest, the total content of the above components is 100wt%;

[0034] Step 2, place the mixed suspension in a high-speed overhead stirrer and stir until uniform, the stirring speed is 1500r / min, and the stirring time is 30min;

[0035] Step 3. Pour the uniformly stirred mixed suspension into a custom-made container, and let it stand for degassing for 24 hours to obtain a homogeneous suspension; the size and shape of the custom-made container match the size and shape of the sample;

[0036] Step 4. Place the homogene...

Embodiment 2

[0039] Example 2 provides a method for preparing a cellulose-sourced carbon-based light-to-heat conversion material for seawater desalination, including the following steps:

[0040] Step 1, mixing nanocellulose, cell regulator, epoxy resin, polyamide resin and water to prepare a mixed suspension; wherein, the contents of each component in the mixed suspension are: nanocellulose: 10wt% 1. Epoxy resin: 3wt%, polyamide resin: 5wt%, cell regulator: 10wt% and the rest of water, the total content of the above components is 100wt%;

[0041] Step 2, place the mixed suspension in a high-speed overhead stirrer and stir until uniform, the stirring speed is 1200r / min, and the stirring time is 20min;

[0042]Step 3. Pour the uniformly stirred mixed suspension into a custom-made container, and let it stand for degassing for 12 hours to obtain a homogeneous suspension; the size and shape of the custom-made container match the size and shape of the sample;

[0043] Step 4. Place the homogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com