Polyacrylonitrile-coated graphene composite material as well as preparation method and application thereof

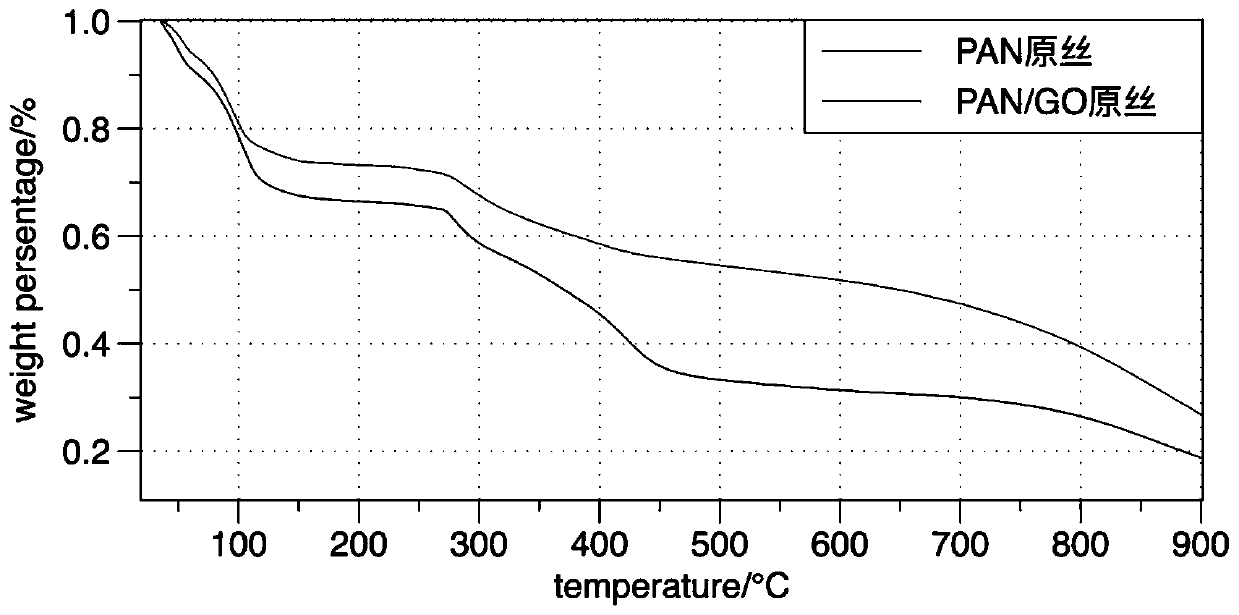

A technology of polyacrylonitrile and composite materials, applied in rayon manufacturing, textile and papermaking, fiber chemical characteristics, etc., can solve the problems of low degree of graphitization, long time, poor orientation of graphite lattice structure, etc., to increase the degree of crystallinity and crystal size, reducing the tendency to build up, and improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

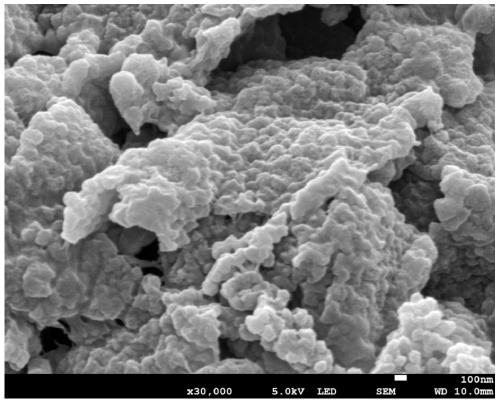

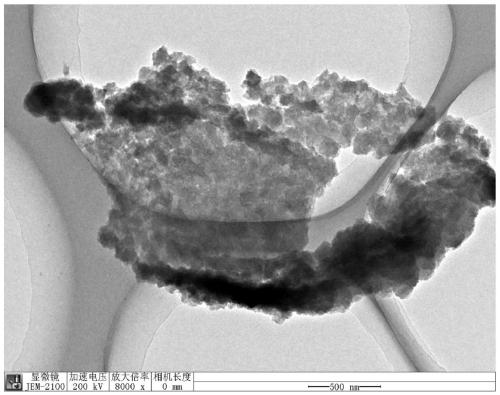

[0037] The preparation method of polyacrylonitrile-coated graphene composite material comprises the steps:

[0038] Control the temperature of the polymerization system to be 50°C, mix 20ml acrylonitrile (accounting for 10wt% of the total mass of the solution), 0.5g graphene (graphene accounts for 3wt% of the total monomer content), and 0.15ml dodecanethiol, and mix them uniformly in 60 minutes A mixed initiator solution consisting of 0.75 g of ammonium sulfite and 0.75 g of ammonium persulfate was added dropwise. After the dropwise addition, the mixture was incubated for 60 minutes. The obtained product was washed with water and dried at 95° C. to obtain the final composite material.

Embodiment 2

[0040] The preparation method of polyacrylonitrile-coated graphene composite material comprises the steps:

[0041] Control polymerization system temperature is 50 ℃, 20ml acrylonitrile (accounting for solution gross mass 10wt%), 0.02g graphene (graphene accounts for 0.1wt% of total monomer content), 0.15ml dodecanethiol are mixed uniformly, at 60 The mixed initiator solution consisting of 0.75g of ammonium sulfite and 0.75g of ammonium persulfate was added dropwise within 1 minute, and kept warm for 60 minutes after the dropwise addition was completed. The obtained product was washed with water and dried at 95°C to obtain the final composite material.

Embodiment 3

[0043] The preparation method of polyacrylonitrile-coated graphene composite material comprises the steps:

[0044] Control the temperature of the polymerization system to be 50°C, mix 20ml acrylonitrile (accounting for 10wt% of the total mass of the solution), 0.8g graphene (graphene accounts for 5wt% of the total monomer content), and 0.15ml dodecanethiol, and mix them uniformly in 60 minutes A mixed initiator solution consisting of 0.75 g of ammonium sulfite and 0.75 g of ammonium persulfate was added dropwise. After the dropwise addition, the mixture was incubated for 60 minutes. The obtained product was washed with water and dried at 95° C. to obtain the final composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com