A kind of SBS high-viscosity modified emulsified asphalt material and its preparation process

A technology for emulsified asphalt and modified asphalt, which is used in building thermal insulation materials, building components, buildings, etc. to achieve the effects of stable storage, low energy consumption and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

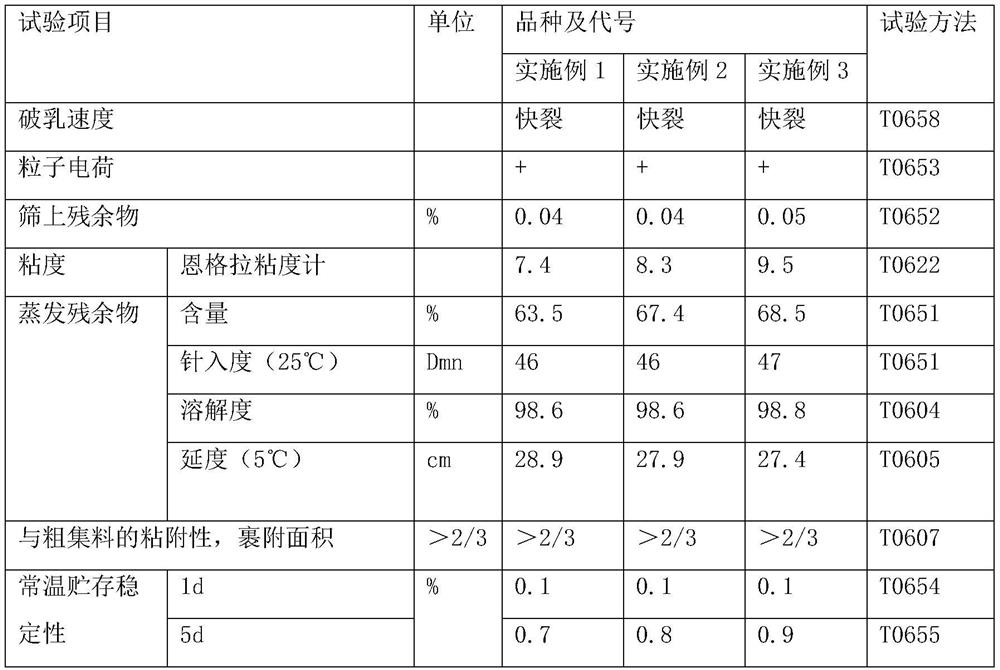

Examples

Embodiment 1

[0037] A kind of SBS high-viscosity modified emulsified asphalt material comprises the following components in parts by mass: 100 parts of base asphalt, 3 parts of styrene butadiene styrene block polymer (SBS), 5 parts of waste rubber powder, 4 parts of compatibilizer, 0.75 parts of plasticizer, 3 parts of tackifier, 1 part of sulfur-containing stabilizer, 1 part of chemical modifier, 0.5 part of polypropylene glycol, 0.05 part of inorganic stabilizer, 0.3 part of emulsifier, 0.3 part hydrochloric acid and 30 parts water.

[0038]The base asphalt is No. 70 grade A road petroleum asphalt; the ratio of styrene to butadiene in the styrene butadiene styrene block polymer is 30:70. The mesh number of the waste rubber powder is 30 mesh; the compatibilizer is heavy aromatic oil; the hydrochloric acid is industrial hydrochloric acid with a mass fraction of 36%; the inorganic stabilizer is calcium chloride; the polypropylene glycol is PPG -400; the tackifier is a thermoplastic resin. ...

Embodiment 2

[0049] A kind of SBS high-viscosity modified emulsified bituminous material, comprises the following components according to mass parts: 100 parts of base asphalt, 4 parts of styrene butadiene styrene block polymer (SBS), 8 parts of waste rubber powder, 5 parts of compatibilizer, 2 parts of plasticizer, 4 parts of tackifier, 0.8 part of sulfur-containing stabilizer, 0.75 part of chemical modifier, 0.4 part of polypropylene glycol, 0.05 part of inorganic stabilizer, 0.3 part of emulsifier, 0.3 part hydrochloric acid and 33 parts water.

[0050] The base asphalt is No. 70 grade A road petroleum asphalt; the ratio of styrene to butadiene in the styrene butadiene styrene block polymer is 40:60. The mesh number of the waste rubber powder is 30 mesh; the compatibilizer is heavy aromatic oil; the hydrochloric acid is industrial hydrochloric acid with a mass fraction of 36%; the inorganic stabilizer is calcium chloride; the polypropylene glycol is PPG -400; the tackifier is a thermop...

Embodiment 3

[0061] A kind of SBS high-viscosity modified emulsified asphalt material comprises the following components in parts by mass: 100 parts of base asphalt, 5 parts of styrene butadiene styrene block polymer (SBS), 6 parts of waste rubber powder, 6 parts of compatibilizer, 2.5 parts of plasticizer, 4 parts of tackifier, 1 part of sulfur-containing stabilizer, 2 parts of chemical modifier, 1 part of polypropylene glycol, 0.05 part of inorganic stabilizer, 0.3 part of emulsifier, 0.3 part hydrochloric acid and 32 parts of water.

[0062] The base asphalt is No. 70 grade A road petroleum asphalt; the ratio of styrene to butadiene in the styrene butadiene styrene block polymer is 40:60. The mesh number of the waste rubber powder is 30 mesh; the compatibilizer is heavy aromatic oil; the hydrochloric acid is industrial hydrochloric acid with a mass fraction of 36%; the inorganic stabilizer is calcium chloride; the polypropylene glycol is PPG -400; the tackifier is a thermoplastic resin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com