Wear-resistant ultraviolet curing magnetic roller coating and preparation method thereof

A magnetic roller and coating technology, applied in the field of coatings, can solve the problems of increased coating brittleness, coating wear, low tensile strength, etc., to reduce shrinkage-shaped defects, improve wear resistance, and enhance wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

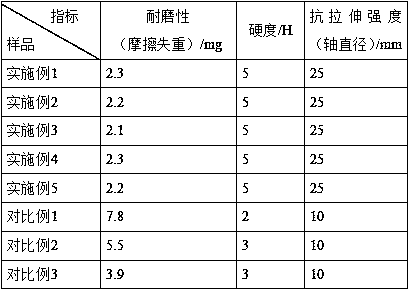

Examples

Embodiment 1

[0022] 13 parts of graphene, 0.6 parts of methyl silicone oil, 6 parts of silicone resin, 0.7 parts of organo-modified polysiloxane acrylic leveling agent, 1.4 parts of fumed silica (0.1-1 μm in diameter), urethane acrylate ( Functionality of 6) 20 parts, 5 parts of hexanediol diacrylate, 4.5 parts of 2-hydroxy-2-methyl-1-phenyl-1-propanone, 7 parts of phytate, titanate coupling 1.4 parts of alicyclic epoxy resin, 10 parts of alicyclic epoxy resin, and 14 parts of zinc powder.

[0023] The above-mentioned coating preparation steps are as follows:

[0024] 1) Weighing: accurately weigh each component according to the formula amount for use;

[0025] 2) Mix urethane acrylate, hexanediol diacrylate and 2-hydroxy-2-methyl-1-phenyl-1-acetone, first stir at a slow speed of 1000rpm for 10min, then adjust the rotation speed to 2500rpm and disperse for 30min to obtain mixture;

[0026] 3) Mix the silicone resin, cycloaliphatic epoxy resin and phytate at 1000rpm for 20min to obtain a...

Embodiment 2

[0030] 12 parts of graphene, 0.8 parts of methyl silicone oil, 4 parts of silicone resin, 0.8 part of organo-modified polysiloxane acrylic leveling agent, 0.8 part of fumed silica (0.1-1 μm in diameter), urethane acrylate ( The functionality is 6) 25 parts, 0.1 part of hexanediol diacrylate, 6 parts of 2-hydroxy-2-methyl-1-phenyl-1-propanone, 4 parts of phytate, titanate coupling 2 parts of alicyclic epoxy resin, 8 parts of alicyclic epoxy resin, and 16 parts of zinc powder.

[0031] The preparation steps of the above coatings are the same as those in Example 1.

Embodiment 3

[0033] 14 parts of graphene, 0.4 parts of methyl silicone oil, 8 parts of silicone resin, 0.5 part of organic modified polysiloxane acrylic leveling agent, 2 parts of fumed silica (0.1-1μm in diameter), urethane acrylate ( Functionality of 6) 15 parts, 10 parts of hexanediol diacrylate, 3 parts of 2-hydroxy-2-methyl-1-phenyl-1-propanone, 10 parts of phytate, titanate coupling 0.75 parts of alicyclic epoxy resin, 12 parts of alicyclic epoxy resin, and 12 parts of zinc powder.

[0034] The preparation steps of the above coatings are the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com