Method for producing coenzyme Q10 by combining plasma action with oxygen limitation

A plasma and coenzyme technology, applied in the field of microbial cultivation, can solve the problems of high power energy consumption and increased production costs, and achieve the effects of high mutation efficiency, simple and efficient operation, and reduced damage and lethal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] This embodiment provides a method for producing coenzyme Q by combining the plasma action with oxygen limitation 10 The method comprises: the step of ARTP mutagenesis; Oxygen limitation screening coenzyme Q 10 Steps for High-Producing Strains; Fermentative Production of Coenzyme Q 10 steps; among them,

[0066] The step of described ARTP mutagenesis comprises:

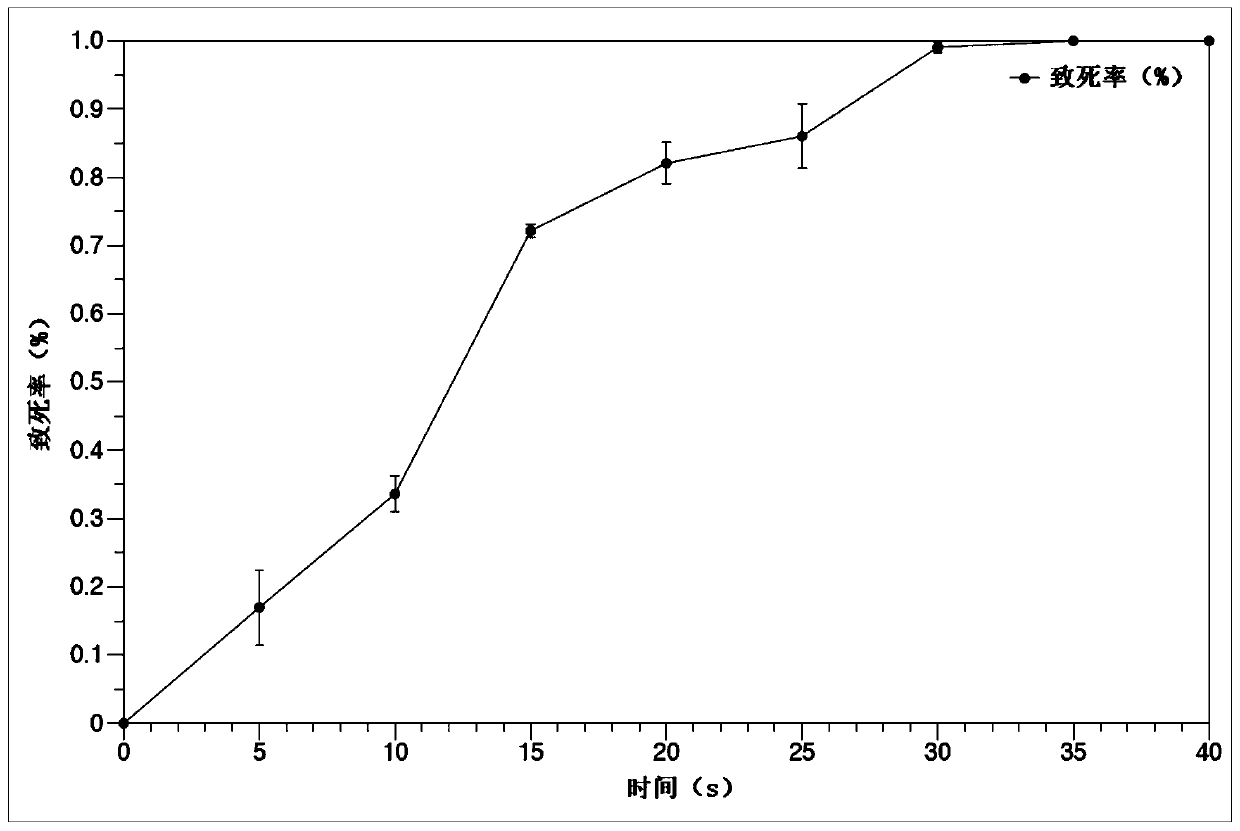

[0067] The bacterial suspension of Rhodobacter sphaeroides is evenly covered on the surface of the slide, and then the slide is placed in the ARTP mutagenesis instrument, and the inert gas is used as the working gas for mutagenesis treatment and elution to obtain the mutagenized bacterial suspension;

[0068] The oxygen-limited screen for coenzyme Q 10 Steps for high-yielding strains, including:

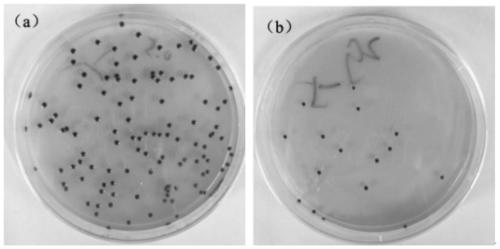

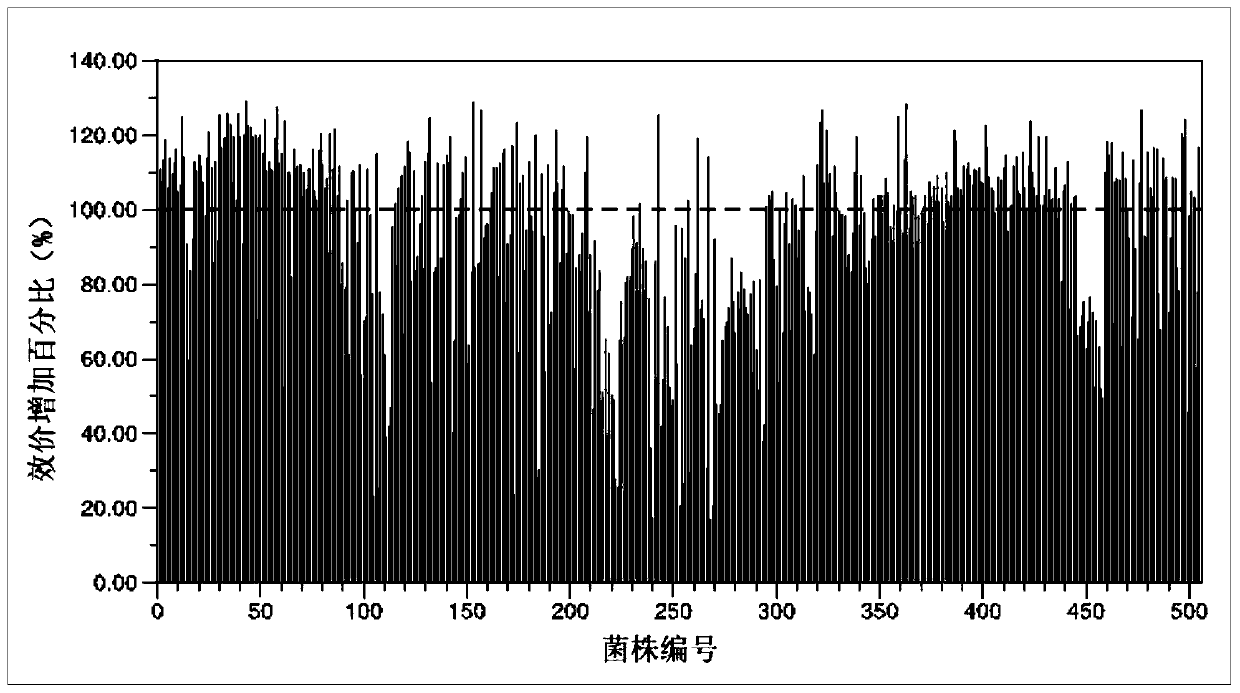

[0069] Under sterile conditions, dilute the bacterium suspension after the mutagenesis, spread it on an oxygen-limited plate containing a plate medium supplemented with 0.2-0.4 g / L anhydrous sodium sulfite, and ca...

Embodiment 2

[0073] This embodiment provides a method for producing coenzyme Q by combining the plasma action with oxygen limitation 10 The method comprises: the step of ARTP mutagenesis; Oxygen limitation screening coenzyme Q 10 Steps for High-Producing Strains; Fermentative Production of Coenzyme Q 10 steps; among them,

[0074] The steps of the ARTP mutagenesis:

[0075] A suitable amount of rhodobacter sphaeroides bacterium suspension is evenly covered on the surface of the slide, and then the slide is placed in the ARTP mutagenesis instrument, with an inert gas as the working gas, at a carrier gas volume of 10SLM (SLM refers to liter per liter under standard conditions) Minutes) for 25s of mutagenesis, elution, the bacteria suspension after the mutagenesis can be obtained;

[0076] The oxygen-limited screen for coenzyme Q 10 Steps for high producing strains:

[0077] Under sterile conditions, the bacterial suspension after the mutagenesis was diluted and coated, grown on an oxyge...

Embodiment 3

[0082] This embodiment provides a method for producing coenzyme Q by combining the plasma action with oxygen limitation 10 The method comprises: the step of ARTP mutagenesis; Oxygen limitation screening coenzyme Q 10 Steps for High-Producing Strains; Fermentative Production of Coenzyme Q 10 steps; among them,

[0083] The step of described ARTP mutagenesis comprises:

[0084] The bacterial suspension of Rhodobacter sphaeroides is evenly covered on the surface of the slide, and then the slide is placed in the ARTP mutagenesis instrument, and the inert gas is used as the working gas for mutagenesis treatment and elution to obtain the mutagenized bacterial suspension;

[0085] The mutagenesis treatment specifically includes: mutagenesis for 25 seconds at a carrier gas volume of 10 SLM (SLM refers to liters per minute under standard conditions).

[0086] The mutated bacterial suspension was spread on a normal plate to grow, and a plate with a single colony was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com