A low temperature weak damage dyeing process for wool

A wool and low-temperature technology, applied in dyeing, textiles and papermaking, etc., can solve the problems of dye uptake rate, reduction of color fixation rate, influence on fiber handle, gloss, vividness, temperature rise, etc., and achieve elongation at break and Increased moisture regain, reduced wool fiber damage, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Wool Raw Material Indicators:

[0030] 70s Australian wool strips;

[0031] Selection and dosage of dyes and auxiliaries:

[0032] Reactive dyes for wool Black ARC, concentration 2.5% (owf); Navy blue ARC-B01, concentration 0.5% (owf);

[0033] Main auxiliary parameters:

[0034] The concentration of formic acid is 2%; the dosage of Yuanming powder is 2% (owf); the dosage of hydrogen peroxide is 15% (owf); the MTG enzyme is 5% (owf).

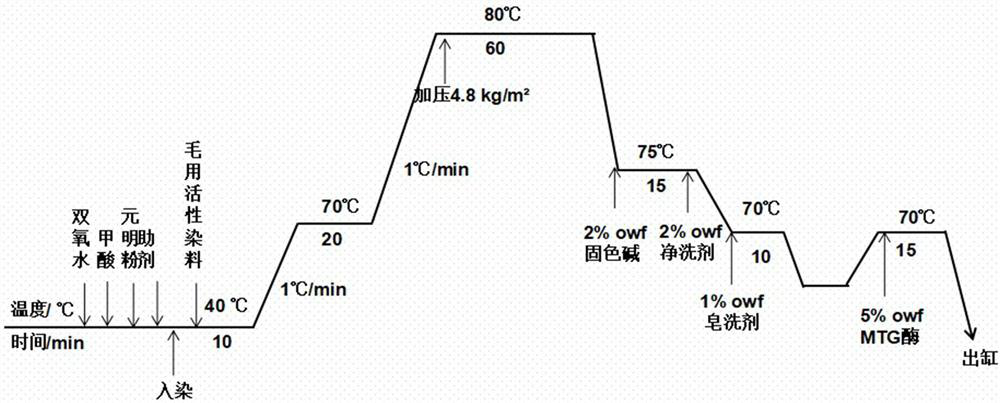

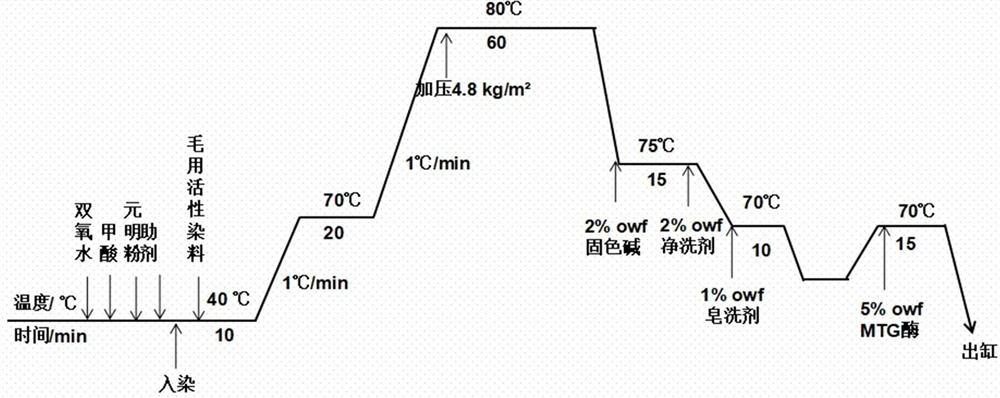

[0035] A low-temperature and weak-damage dyeing process for wool, such as figure 1 As shown, proceed according to the following process steps:

[0036] (1) Pre-treatment: Put the wool ball into the washing machine, add 2% (owf) washing liquid and adjust the pH to 7.5, and keep the water temperature at 55°C for 10 minutes. After washing, dry the wool quickly, and put it into the dyeing vat for water to keep the water circulation system running normally;

[0037] (2) Hydrogen peroxide-formic acid oxidation pretreatment: heat up ...

Embodiment 2

[0048] Wool Raw Material Indicators:

[0049] 70s Australian preshrunk wool strips

[0050] Selection and dosage of dyes and auxiliaries:

[0051] Reactive dyes for wool Black ARC, concentration 2.5% (owf); Navy blue ARC-B01, concentration 0.5% (owf);

[0052] Main auxiliary parameters:

[0053] The concentration of formic acid is 2%; the dosage of Yuanming powder is 2% (owf); the dosage of hydrogen peroxide is 15% (owf); the MTG enzyme is 5% (owf).

[0054] A low-temperature and weak-damage dyeing process for wool, such as figure 1 As shown, proceed according to the following process steps:

[0055](1) Pre-treatment: Put the wool ball into the washing machine, add 2% (owf) washing liquid and adjust the pH to 7.5, and keep the water temperature at 55°C for 10 minutes. After washing, dry the wool quickly, and put it into the dyeing vat for water to keep the water circulation system running normally;

[0056] (2) Hydrogen peroxide-formic acid oxidation pretreatment: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com