Copper smelting anode furnace redox intelligent endpoint judgment system

An end point judgment and anode furnace technology, applied in the field of redox intelligent end point judgment system of copper smelting anode furnace, can solve the problems of over-oxidation or under-reduction, high cost, undisclosed air supply volume and air supply pressure digital-to-analog relationship, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be described in further detail below with specific examples, but the present invention is not limited to the following specific examples.

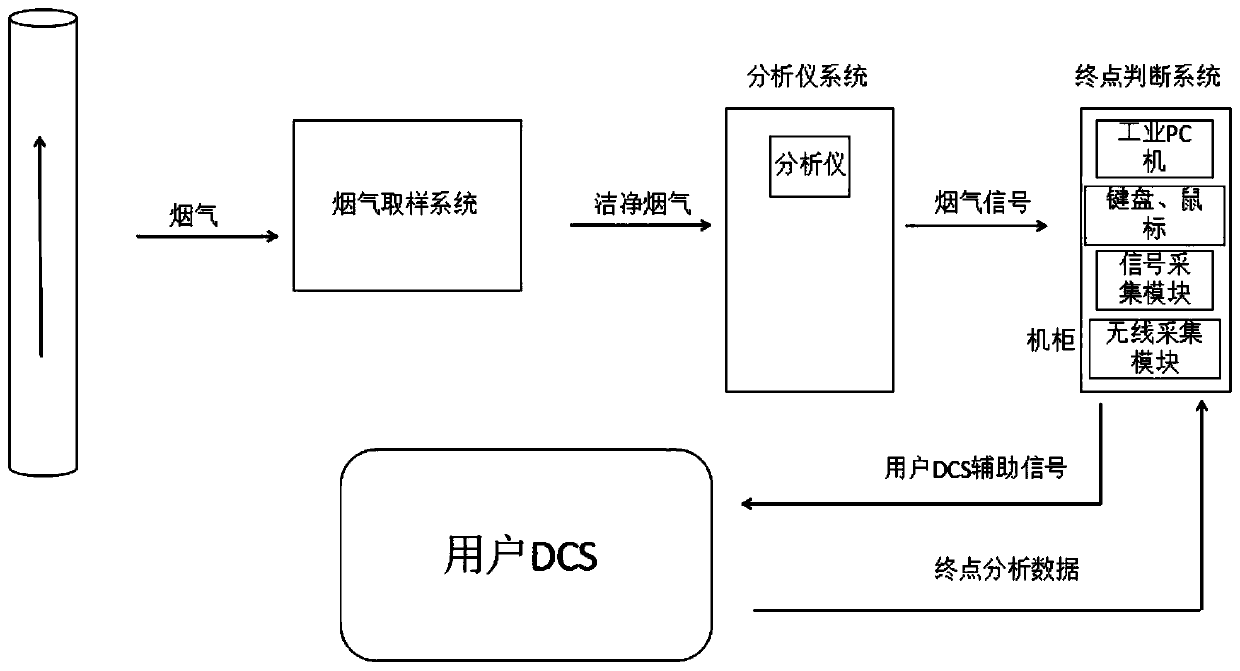

[0065] refer to figure 1 , the copper smelting anode furnace redox intelligent endpoint judgment system of the present invention is used to communicate with the flue gas analyzer and the user's DCS system; the flue gas analyzer is connected to the analyzer system, and the analyzer system is connected to the flue gas sampling system. Gas analyzer detects SO in anode furnace 2 , O 2 , CO, CO 2 The real-time value of the concentration; the flue gas analyzer, the analyzer system and the flue gas sampling system are all prior art, for details, please refer to Chinese patent CN109797291A. The user DCS system is used to control the reaction in the anode furnace, and the user DCS system is also an existing technology.

[0066] The endpoint judging system of the present invention includes a signal acquisition m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com