Preparation method of ZnIn2S4 nanosheet array rich in surface S vacancies

A nanosheet array and nanoarray technology, which is applied in the field of semiconductor photocatalytic material preparation, can solve the problems of difficult photogenerated carrier transport, low photoelectric catalytic performance, and low photoelectric performance, and achieve good photocatalytic potential and superior performance , the effect of reducing the preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

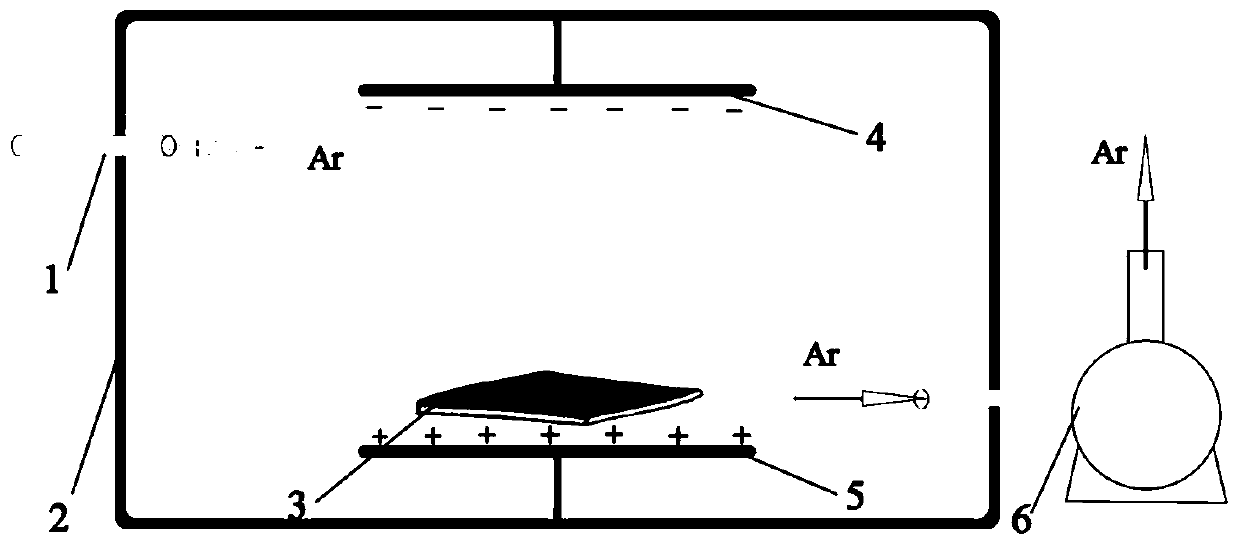

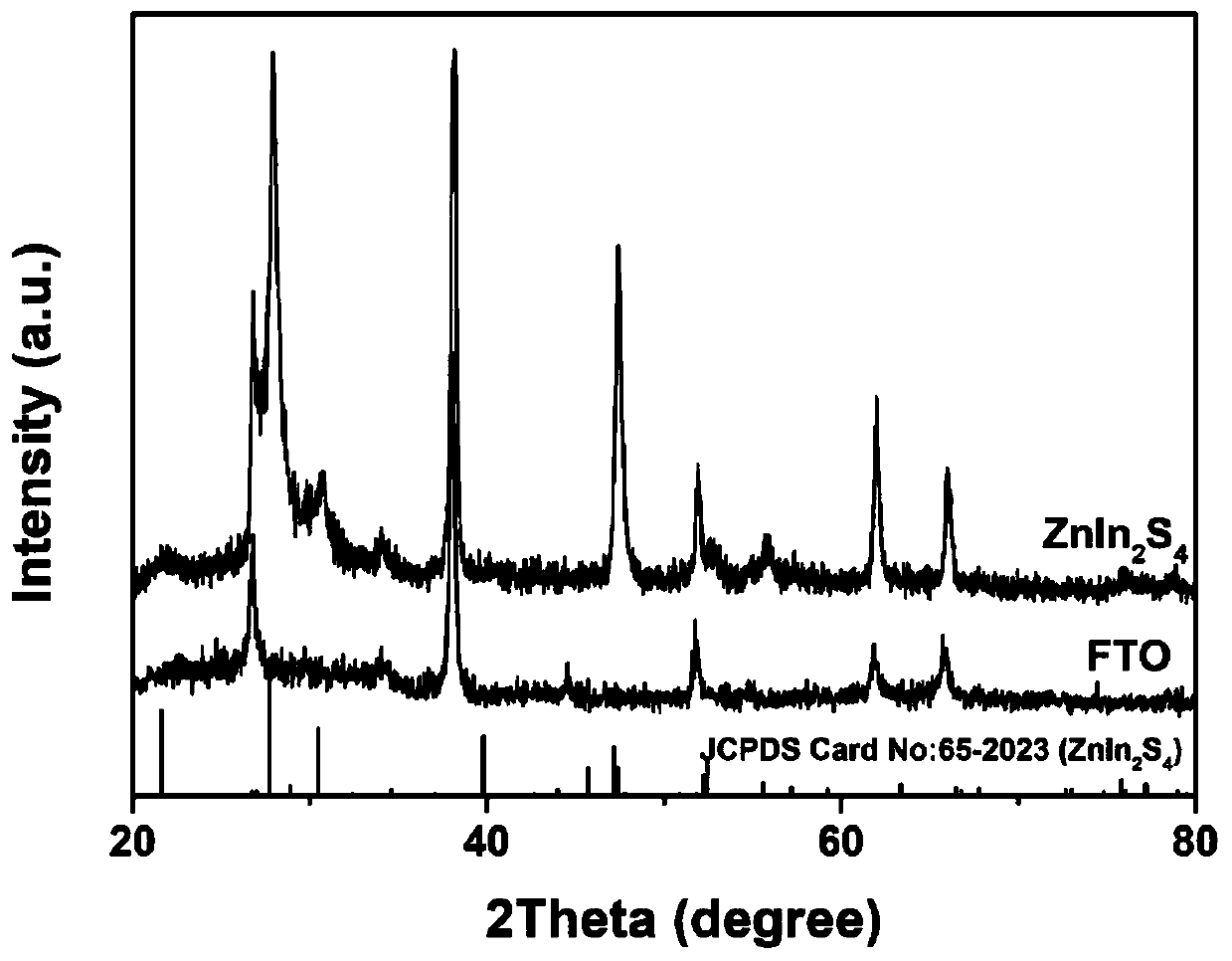

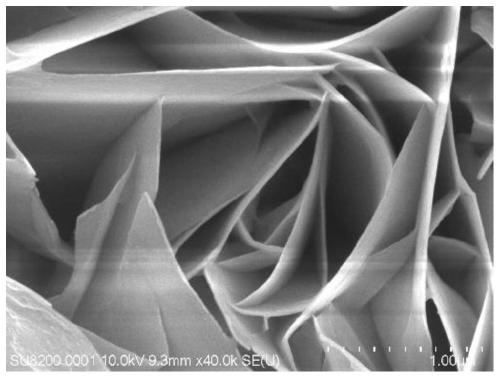

[0036] Surface-rich ZnIn with S vacancies 2 S 4 The preparation method of the nano-array is: the preparation method of the photocatalytic material, first prepare ZnIn 2 S 4 Nanosheet array, ZnIn 2 S 4 The nanosheet array grows vertically on the substrate, the thickness of the nanosheet is 30-50nm, and has a large specific surface area; then a large number of S vacancies are introduced on the surface by plasma cleaning to improve its photocatalytic performance, and the plasma cleaning power is adjusted to Realize the introduction of different amounts of S vacancies, a large number of S vacancies introduced in ZnIn 2 S 4 A local energy level is formed on the lower side of the conduction band, and a surface-rich ZnIn with S vacancies is prepared. 2 S 4 Nano-array electrode sheet, reducing the bandgap width and improving ZnIn 2 S 4 Light absorption properties of nanoarray electrode sheets. The experiment will be described in further detail in conjunction with the accompa...

Embodiment 1

[0050] Example 1: Preparation of 40W cleaning to obtain ZnIn with S vacancies on the surface 2 S 4 Nanoarray electrode sheet.

[0051] will grow with ZnIn 2 S 4 The nano-array FTO was placed in a plasma cleaning machine, vacuumed to 5.0Pa, Ar gas was introduced, and the voltage of the poles in the cleaning chamber was adjusted to 120V. Adjust the vacuum pump to keep the cleaning power at 40W, and clean for 30min. Cooling to get 40W cleaned ZnIn with S vacancies on the surface 2 S 4 Nanoarray electrode sheet.

Embodiment 2

[0052] Example 2: Preparation of 60W cleaning to obtain ZnIn with S vacancies on the surface 2 S 4 Nanoarray electrode sheet.

[0053] will grow with ZnIn 2 S 4 The nano-array FTO is placed in the plasma cleaning machine, pumped to 5.0Pa, and Ar gas is introduced to adjust the voltage of the two poles in the cleaning chamber to 120V. Adjust the vacuum pump to keep the cleaning power at 60W, and clean for 30min. Cooling to get 60W cleaning ZnIn with S vacancies on the surface 2 S 4 Nanoarray electrode sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com