Preparation method of GO/MoS2 electrode for removing lead ions in water by electrochemical method

An electrochemical, lead ion technology, applied in the field of materials, can solve the problem of less lead ions removed by capacitive deionization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

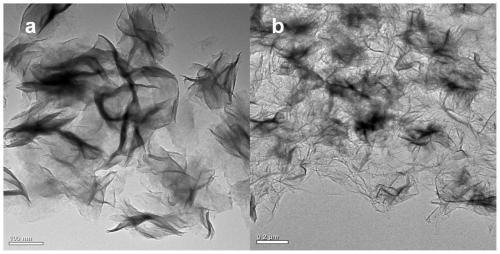

[0021] Specific embodiment one: a kind of GO / MoS that removes lead ions in water body by electrochemical method in this embodiment 2 Electrode preparation method, it is carried out according to the following steps:

[0022] 1. Preparation of Graphene Oxide

[0023] Take graphite powder and sodium nitrate, add H under ice bath conditions 2 SO 4 Stir well, then add KMnO 4 , stirred in a water bath at 36°C for 1h to form a viscous slurry; then added deionized water to the slurry, stirred at a temperature of 90°C for 15min, added deionized water, and added H 2 o 2 , the solution turns from dark brown to yellow; wash and filter with 1M hydrochloric acid, wash with deionized water repeatedly until the product turns from yellow to black, and the black product is dispersed in deionized water at 4000rpm·min -1 Centrifuge for 5 minutes to remove the particles in the lower layer, repeat the washing 4-5 times until there are no particles, 8000rmp·min -1 Centrifuge at high speed for ...

specific Embodiment approach 2

[0032] Specific embodiment two: the difference between this embodiment and specific embodiment one is: H 2 SO 4 The mass percent composition of is 98wt%. The other specific embodiments are the same.

specific Embodiment approach 3

[0033] Specific embodiment three: the difference between this embodiment and specific embodiment one is: KMnO 4 Add slowly. The other specific embodiments are the same.

PUM

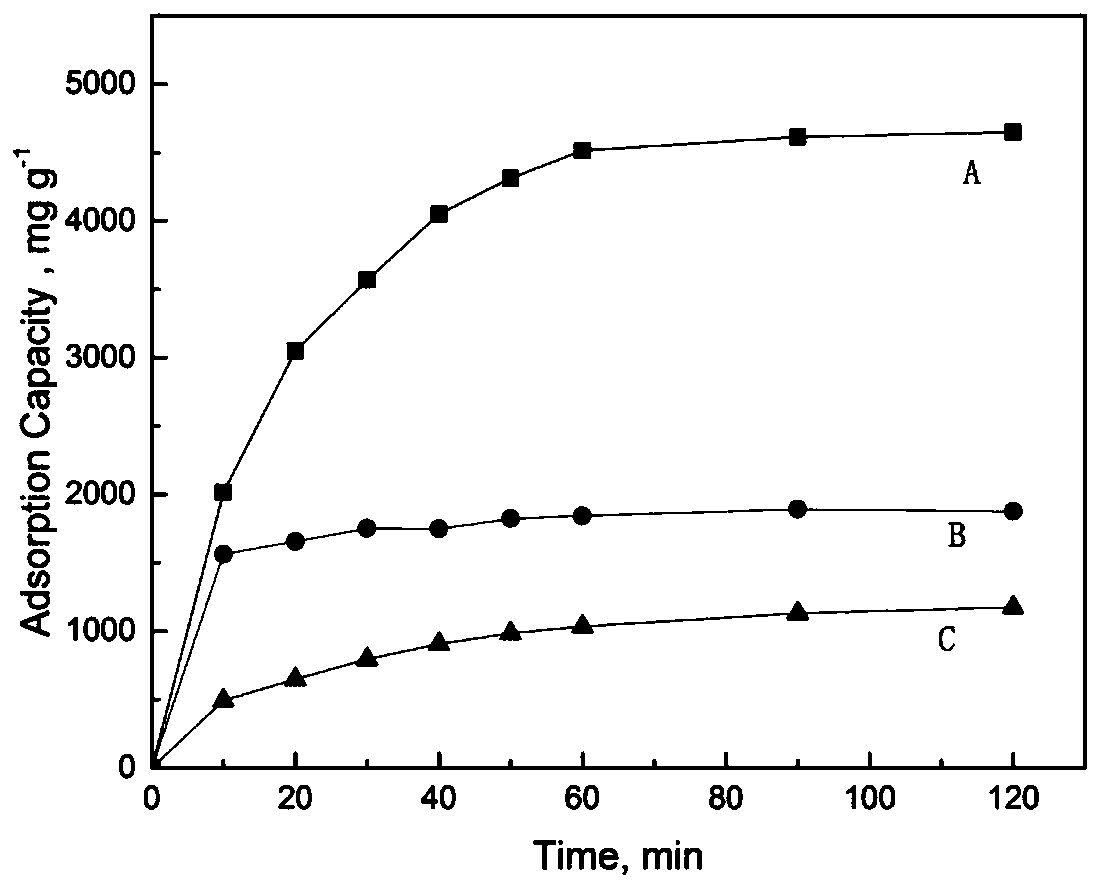

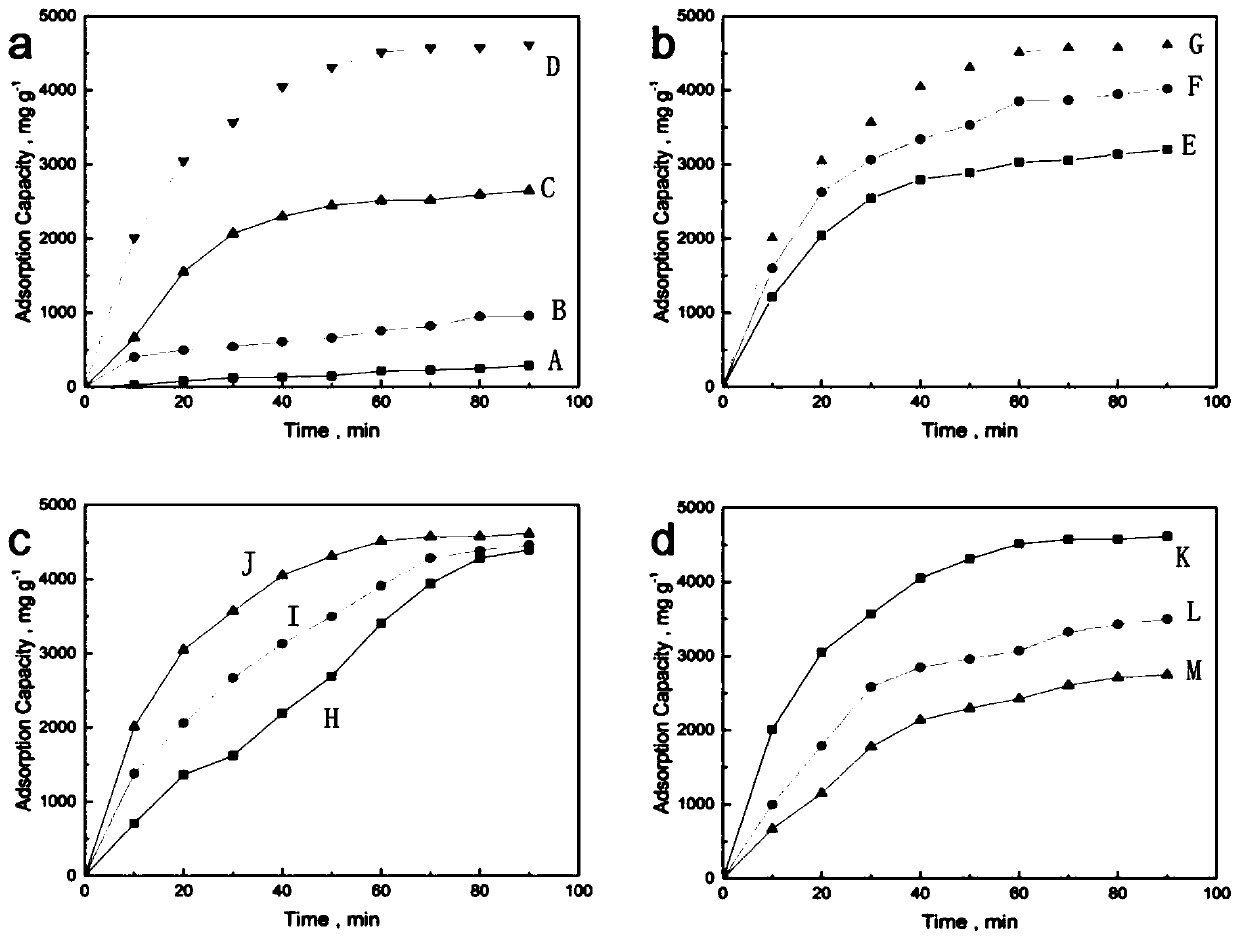

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com