A kind of ceramic base film molding paste and its preparation method and a crystal overlay drawing method

A molding paste and ceramic technology, applied in the field of ceramic handicrafts, can solve the problems of high toxicity, excessive toxic substances, and inability to bas-relief crystal color imaging, etc., to achieve crystal clear color, strong coverage, and unique crystal refraction visual effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

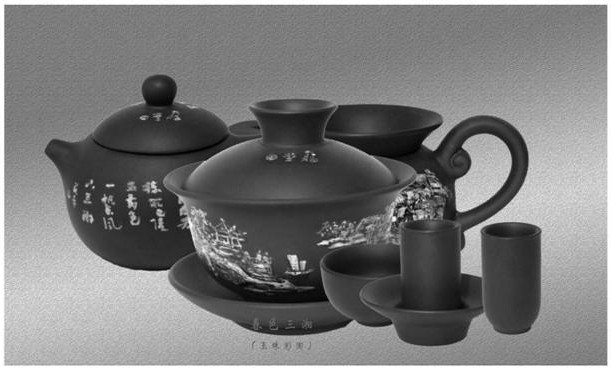

Image

Examples

preparation example Construction

[0067] The present invention also provides a method of preparing a ceramic primary membrane plastic paste according to the above technical solution, including the following steps:

[0068] a) Mix quartz, sodium carbonate, titanium oxide, tin oxide, zinc oxide, and porcelain mud, calcination, and then sieved, and obtain raw materials mixed powder;

[0069] b) Add silver powder and pearl powder to the raw material mixed powder obtained in step a), and stir the purity and stirring to give ceramic primer plastic cream.

[0070] The present invention first combines quartz, sodium carbonate, titanium oxide, tin oxide, zinc oxide, and porcelain mud, calcined, and then sieved, and obtained raw material mixing powder. In the present invention, the quartz, sodium carbonate, titanium oxide, tin oxide, zinc oxide, and porcelain mud are the same as described in the above technical solution, and will not be described herein. The present invention is not particularly limited to the mixing manner...

Embodiment

[0107] (1) The raw material mixed powder formulation of ceramic primer plastic paste is as follows: Quartz 40Wt%, sodium carbonate 20 wt%, titanium oxide 10 wt%, zinc oxide 5 wt% and porcelain mud 10 wt%; After mixing, it is fine, and then calcined in the crucible to calcination, and then the 250 mesh sieve is again raised to obtain a raw material mixed powder.

[0108] (2) Add 10% by weight of the silver powder, 5 wt% pearl powder to the raw material mixed powder obtained by step (1), and is fully stirred with pure water, and fully agitated to obtain a ceramic primary membrane paste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com