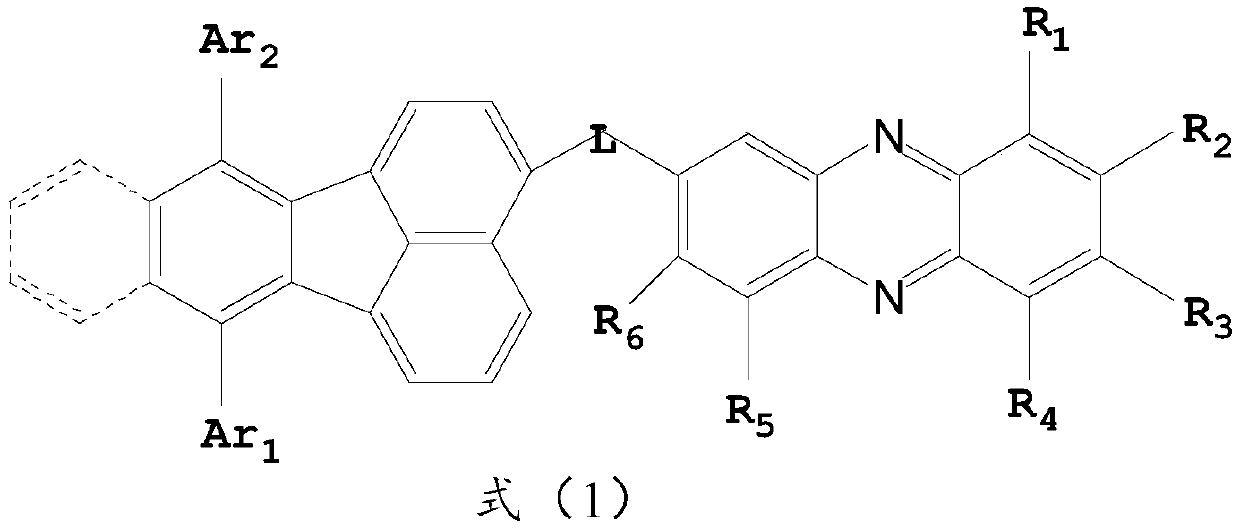

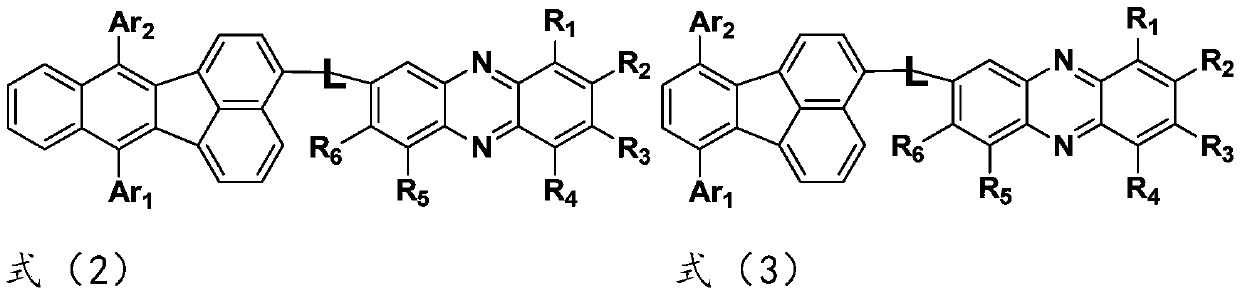

Phenazine group substituted polycyclic aromatic hydrocarbon derivative and application thereof

A technology of fused-ring aromatic hydrocarbons and fused-ring aromatic hydrocarbons, which is applied in the field of organic electroluminescence, can solve the problems of increasing the complexity of the device manufacturing process, reducing the cost of OLEDs, disadvantages, etc., achieving good electron acceptance capabilities, improving luminous efficiency, and reducing work The effect of voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 12

[0048] The synthesis of embodiment 12-bromophenazine

[0049]

[0050]Add 3.91 grams of 4-bromo-o-phenylenediamine (molecular weight 186, 0.021mol), 2.27 grams of o-benzoquinone (molecular weight 108, 0.021mol), and ethanol (40 ml) into a 250ml three-necked flask. 0.2 gram of concentrated sulfuric acid was reacted at 65°C for 4 hours. After the reaction was over, it was cooled to room temperature, filtered, and washed with ethanol and petroleum ether successively to obtain 5.02 grams of intermediate compound 2-bromophenazine (molecular weight 258), with a yield of 92.6 %.

Embodiment 2

[0052] Compounds are synthesized according to the following reactions

[0053]

[0054] 1000 ml three-necked flask equipped with magnetic stirring and nitrogen protection, add 5.16 g of 2-bromophenazine (molecular weight 258, 0.02 mol), 11.0 g of 9,10-bis(naphthalene-2-yl)anthracene-2-boronic acid (molecular weight 474 , 0.022mol), tetrakis ((triphenylphosphine) palladium 1.16g (molecular weight 1154, 0.001mol), 80ml of aqueous sodium carbonate solution of 2M, toluene 80ml, ethanol 80ml, after argon replacement, reflux, use thin-layer chromatography ( TLC) method monitoring reaction, after 4.5 hours, TLC finds that raw material bromide reaction is complete, only product point.Cool down, separate organic layer, evaporate to dryness, column chromatography, ethyl acetate / sherwood oil washing, obtain 9.94g chemical formula and generate The compound shown in the compound has a molecular weight of 608 and a yield of 81.7%.

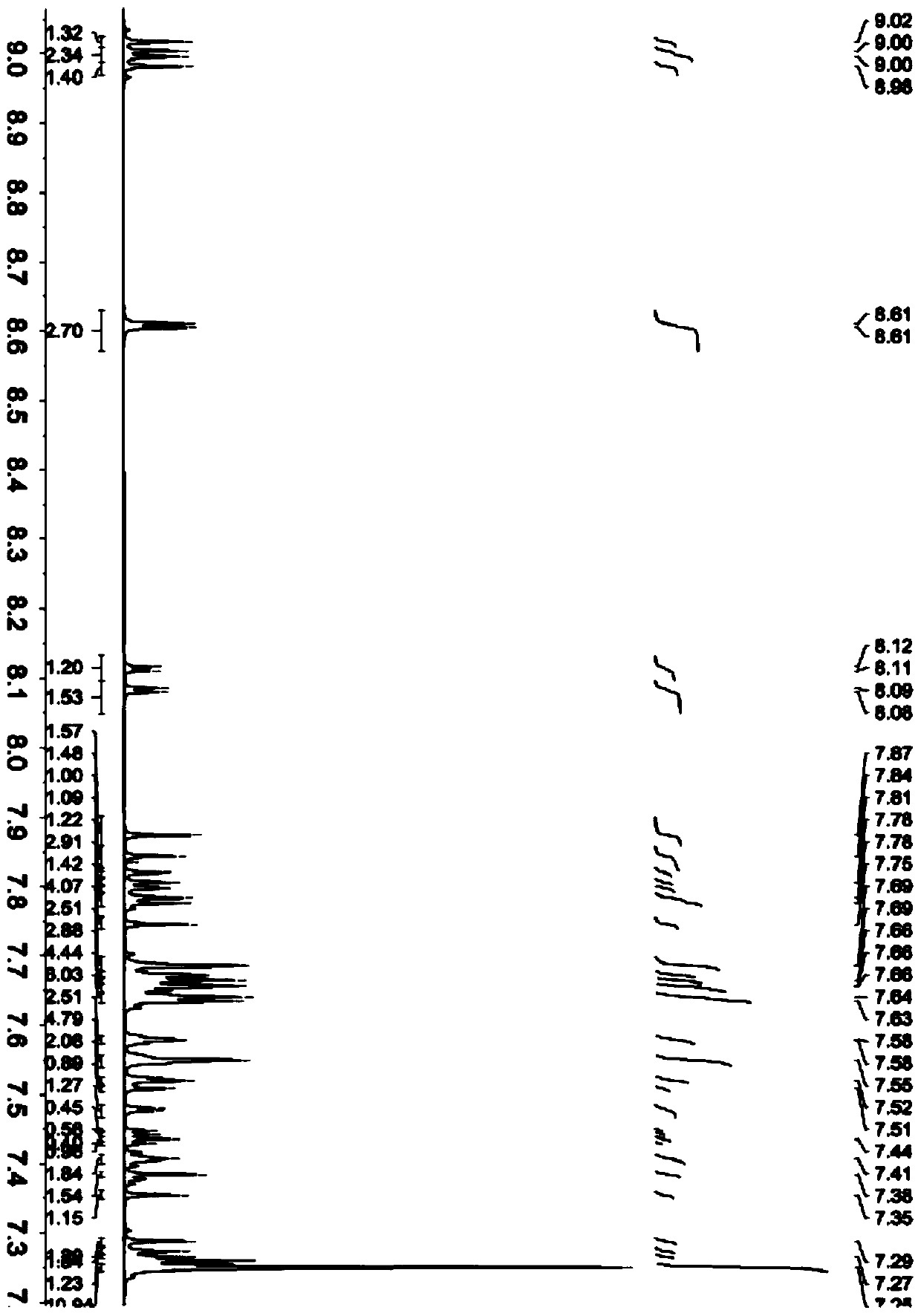

[0055] Product MS (m / e): 608, elemental analysis (C 4...

Embodiment 3

[0057] Synthesis of compound shown in formula (5)

[0058] The synthesis steps are the same as in Example 2, except that 9,10-bis(naphthalene-2-yl)anthracene-2-boronic acid is changed to 7-(naphthalene-2-yl)triphenylene-2-boronic acid, and other reagents remain unchanged. The compound represented by formula (5) was obtained.

[0059] Product MS (m / e): 582, elemental analysis (C 44 h 26 N 2 ): theoretical value C: 90.69%, H: 4.50%, N: 4.81%; measured value C: 90.64%, H: 4.52%, N: 4.84%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com