Low-molecular-weight high trans-1,4-polyisoprene and preparation method thereof

A polyisoprene, low molecular weight technology, applied in the field of conjugated diene catalytic polymerization, can solve the problems of reducing the double bond electron cloud density of the molecular chain, difficult to control the cyclization side reaction, and reducing the cyclization side reaction, etc. Good controllable polymerization effect, low polymerization side reaction, high double bond retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0032] Specific embodiment 1: The specific steps of a method for preparing a low molecular weight, high trans-1,4-polyisoprene of this embodiment are as follows:

[0033] Under argon atmosphere, add catalyst (2.8mg, 10μmol, 1equiv.), ionic liquid ([C 4 MPyr][NTf 2 ], 0.5mL) and isoprene monomer (20mmol, 2mL, 2000equiv.), polymerize at 25°C for 24h while stirring, quench the reaction with 10mL of methanol, filter, wash the product twice with methanol, and vacuum Dry to obtain low molecular weight, high trans-1,4-polyisoprene;

[0034] The structural formula of the catalyst (2.8 mg, 10 μmol, 1 equiv.) in this embodiment is

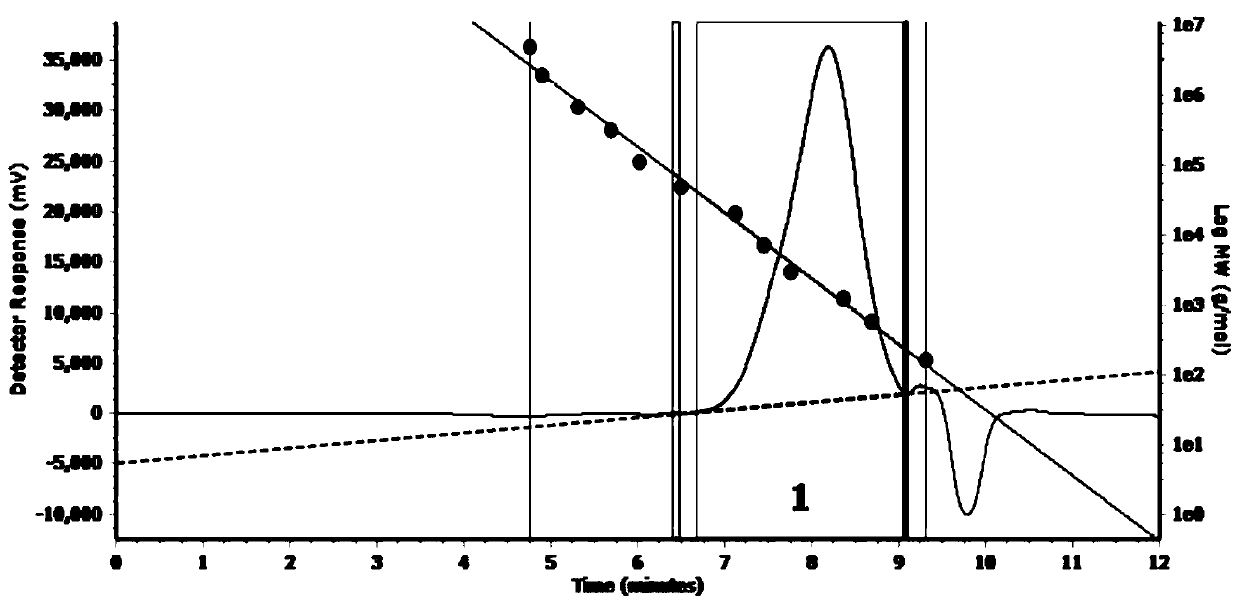

[0035] Results: The yield was 95%, the double bond retention (DB) was 88%, and the number average molecular weight (M n ) Is 874g / mol, molecular weight distribution (PDI) is 2.1; selectivity: trans-1,4 structure accounts for 96%, 3,4- structure accounts for 4%.

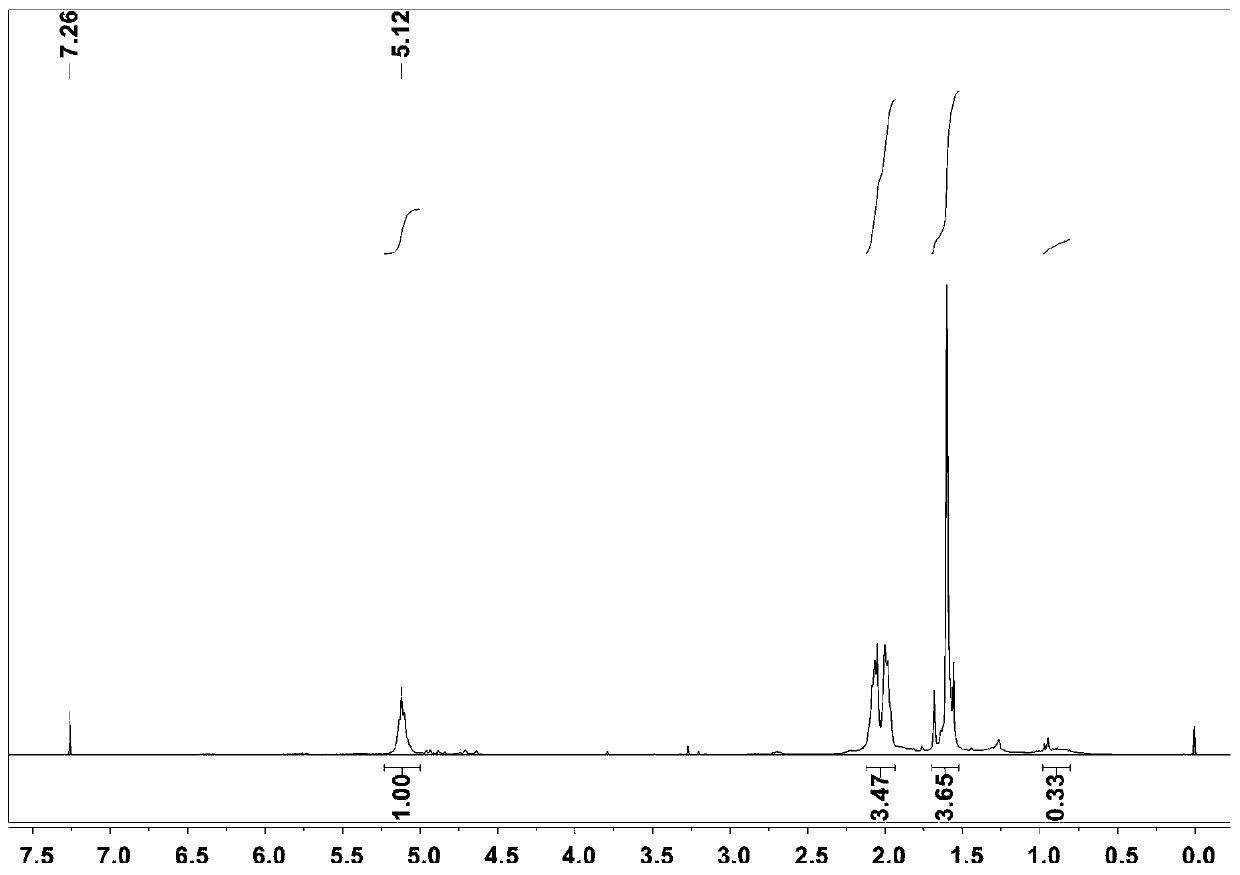

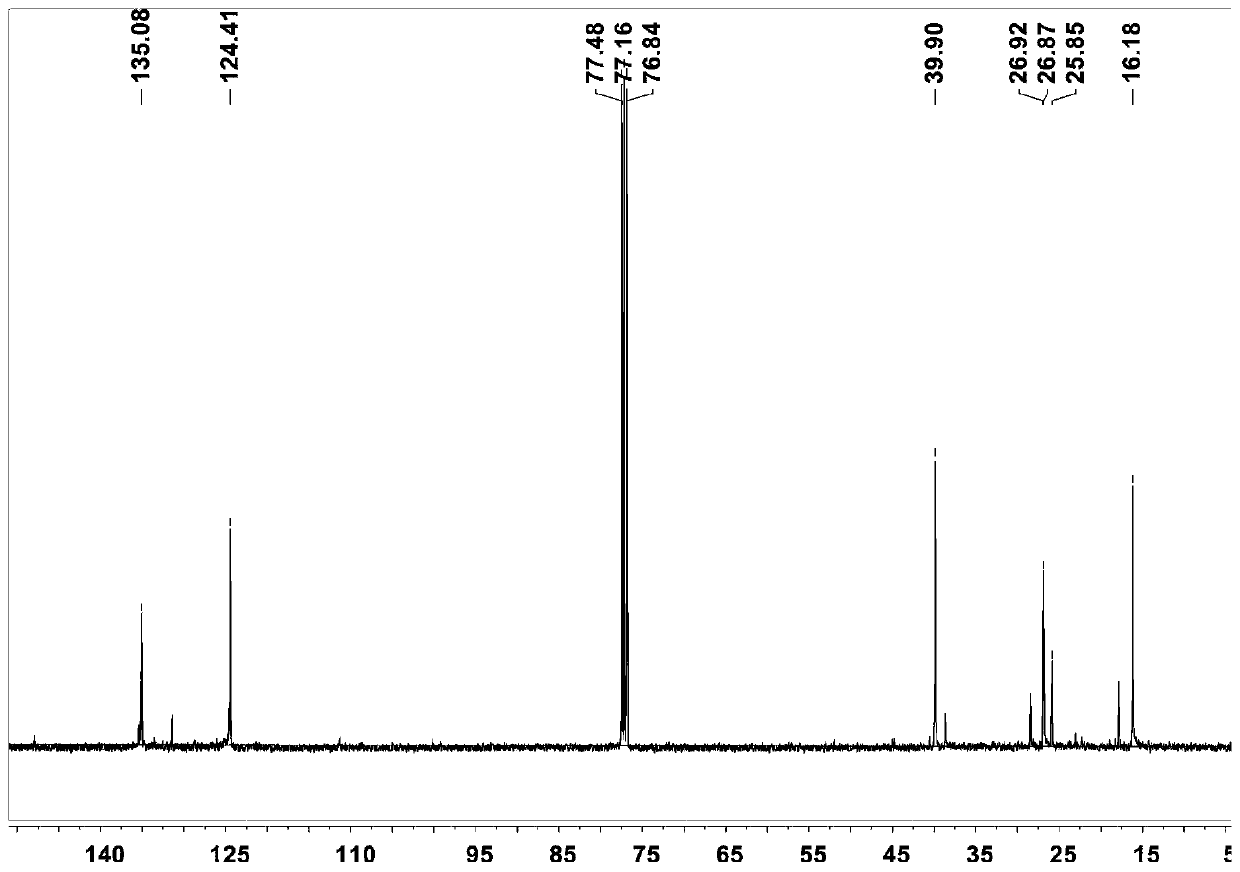

[0036] figure 1 The low molecular weight, high trans-1,4-polyisoprene obtained in this embodiment 1 HNM...

specific Embodiment approach 2

[0040] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the polymerization reaction time is 28 hours, and the other steps and parameters are the same as Embodiment 1.

[0041] Result: Yield> 99%, double bond retention rate (DB) is 83%, M n It is 985g / mol, PDI is 2.2; Selectivity: trans-1,4 structure accounts for 97%, 3,4- structure accounts for 3%.

specific Embodiment approach 3

[0042] Specific embodiment three: The specific steps of the preparation method of a low molecular weight, high trans-1,4-polyisoprene of this embodiment are as follows:

[0043] Under argon atmosphere, add catalyst (2.8mg, 10μmol, 1equiv.), ionic liquid ([C 4 MPyr][NTf 2 ], 1.25mL) and isoprene monomer (50mmol, 5mL, 5000equiv.), polymerize at 25℃ for 28h while stirring, quench the reaction with 10mL of methanol, filter, wash the product twice with methanol, and vacuum Dry to obtain low molecular weight, high trans-1,4-polyisoprene;

[0044] The structural formula of the catalyst (2.8 mg, 10 μmol, 1 equiv.) in this embodiment is

[0045] Result: Yield> 99%, double bond retention rate (DB) is 87%, M n It is 998g / mol, PDI is 2.4; selectivity: trans-1,4 structure accounts for 96%, 3,4- structure accounts for 4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com