Method for improving stability of mulberry red pigment

A technology for red pigment and stability, applied in the field of improving the stability of mulberry red pigment, can solve the problems of changing the original state of the product, high processing cost, poor long-term protection effect, etc., to reduce loss, simple operation steps, and improve stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

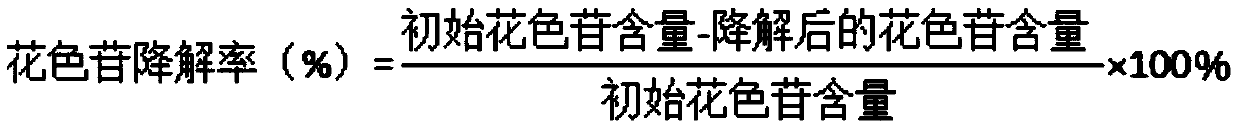

Image

Examples

Embodiment 1

[0023] Disperse the defatted soybean meal with deionized water to 100g / L, adjust the pH to 8.0 with 2M NaOH, stir at room temperature for 2h, centrifuge (10000g, 20min), take the supernatant, adjust the pH of the supernatant to 4.5 with 2M HCI, let stand 30min, centrifugation (3300g, 20min), can obtain soybean protein precipitation, precipitation adds deionized water redissolution, makes soybean protein dispersion solution, and described soybean protein dispersion solution is dissolved in the 20mM citric acid-hydrogen phosphate of pH6.3 In sodium buffer solution, make mother liquor, add soybean protein and anthocyanin into citric acid-dipotassium hydrogen phosphate buffer solution according to the mass ratio of soybean protein: anthocyanin 1:2, stir at 500rpm at room temperature for 1h, fully mix Uniformly, the anthocyanin concentration in the solution after mixing is 0.2 mg / mL.

Embodiment 2

[0025] Disperse the defatted soybean meal with deionized water to 100g / L, adjust the pH to 8.0 with 2M NaOH, stir at room temperature for 2h, centrifuge (10000g, 20min), take the supernatant, adjust the pH of the supernatant to 4.5 with 2M HCI, let stand 30min, centrifugation (3300g, 20min), can obtain soybean protein precipitation, precipitation adds deionized water redissolution, makes soybean protein dispersion solution, and described soybean protein dispersion solution is dissolved in the 20mM citric acid-hydrogen phosphate of pH6.3 Sodium buffer solution, make mother liquor, add soybean protein and anthocyanin into citric acid-dipotassium hydrogen phosphate buffer solution according to the mass ratio of soybean protein:anthocyanin 1:1, stir at 500rpm at room temperature for 1h, fully mix Uniformly, the anthocyanin concentration in the solution after mixing is 0.2 mg / mL.

Embodiment 3

[0027] Disperse the defatted soybean meal with deionized water to 100g / L, adjust the pH to 8.0 with 2M NaOH, stir at room temperature for 2h, centrifuge (10000g, 20min), take the supernatant, adjust the pH of the supernatant to 4.5 with 2M HCI, let stand 30min, centrifugation (3300g, 20min), can obtain soybean protein precipitation, precipitation adds deionized water redissolution, makes soybean protein dispersion solution, and described soybean protein dispersion solution is dissolved in the 20mM citric acid-hydrogen phosphate of pH6.3 Sodium buffer solution, make mother liquor, add soybean protein and anthocyanin into citric acid-dipotassium hydrogen phosphate buffer solution according to the mass ratio of soybean protein:anthocyanin 5:1, stir at 500rpm at room temperature for 1h, fully mix Uniformly, the anthocyanin concentration in the solution after mixing is 0.2 mg / mL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com