Corrosive liquid and preparation method of chip mesa

A technology of etching liquid and mesa, which is applied in the direction of chemical instruments and methods, final product manufacturing, surface etching composition, etc., can solve the problems of uneven etching rate of chip mesa, uneven etching rate, rough etching surface, etc. , to achieve large-scale mass production, less damage to the chip surface, and good uniformity of the etched surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In a second aspect, the present invention provides a method for preparing a chip mesa, wherein a substrate provided with a photoresist is placed in the etching solution of the first aspect of the present invention for etching, and then a mesa is formed on the surface of the substrate.

[0035] It can be understood that the substrate provided with photoresist in the present invention is: the cleaned substrate is sequentially subjected to processes such as leveling, exposure, development, and film hardening, and the photoresist is used to form a layer on the surface of the substrate to be etched. patterned substrate.

[0036] Compared with dry etching, wet etching has the following advantages: there is no need to grow a dielectric film that blocks etching, and only one photoresist protection is required to complete it. The etching rate is basically a linear relationship, and the repeatability is better than that of similar dry etching. The process is simple, stable and lo...

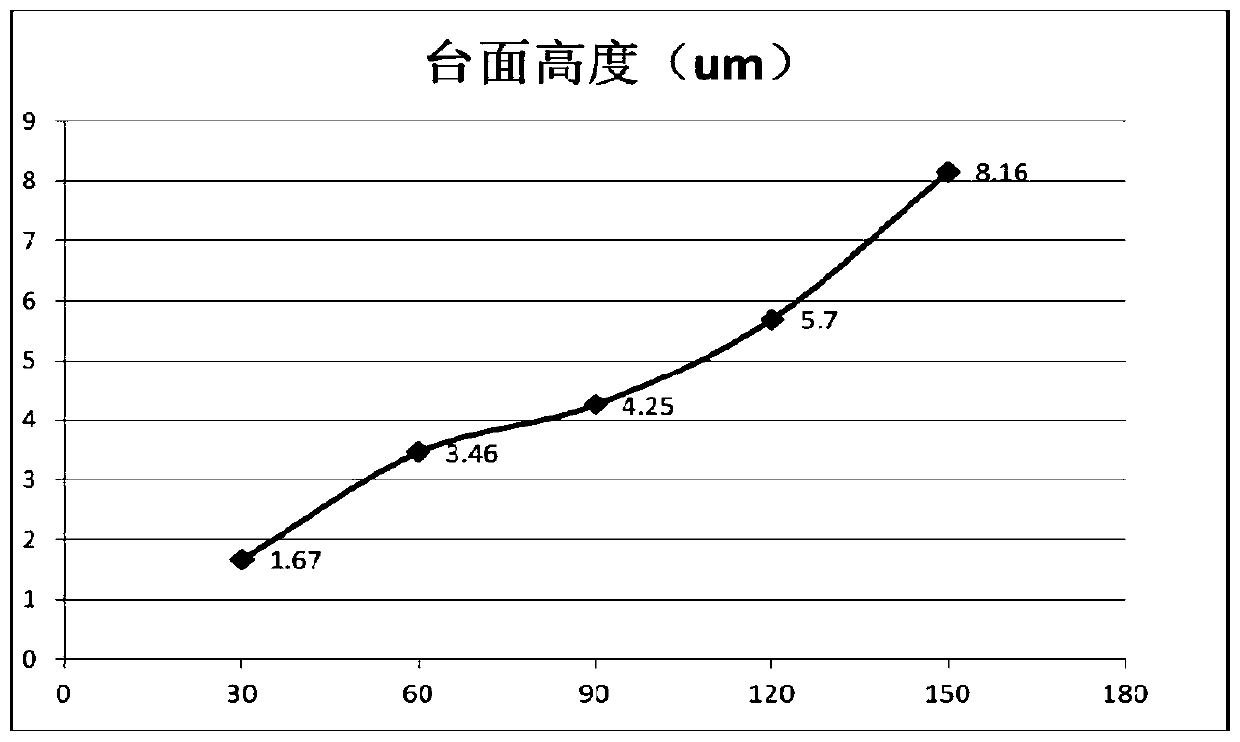

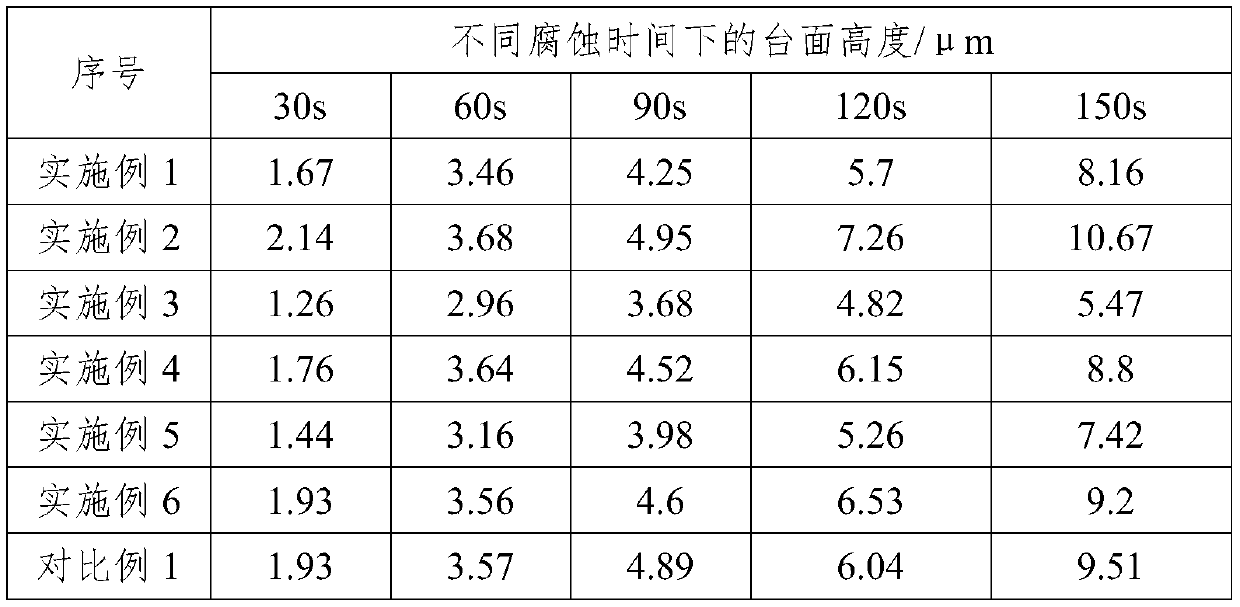

Embodiment 1

[0039] S10, preparation of corrosion solution

[0040] The proportioning of each raw material of the corrosion solution prepared in the present embodiment is as follows:

[0041] Potassium dichromate: hydrobromic acid (40% volume fraction): water=1g: 20ml: 60ml, this corrosion solution preparation method comprises the following steps:

[0042] S101, mixing 5g of potassium dichromate with 300ml of deionized water;

[0043] S102. Add 100ml of hydrobromic acid to the above mixed liquid, and stir fully to obtain the required corrosion solution;

[0044] S20, chip mesa etching

[0045] S201. The cleaned In / InGaAs substrate is sequentially subjected to processes such as uniform coating, exposure, development, and film hardening, and a photoresist is used to form a pattern on the surface of the substrate to be etched;

[0046] S202, putting the above-mentioned substrate patterned with photoresist into the etching solution, and standing for etching for a certain period of time;

...

Embodiment 2

[0051]S10, preparation of corrosion solution

[0052] The proportioning of each raw material of the corrosion solution prepared in the present embodiment is as follows:

[0053] Potassium dichromate: hydrobromic acid (40% volume fraction): water=1.9g: 45ml: 100ml, this corrosion solution preparation method comprises the following steps:

[0054] S101, mixing 5.7g potassium dichromate with 300ml deionized water;

[0055] S102. Add 135ml of hydrobromic acid to the above mixed liquid, and stir well to obtain the required corrosion solution;

[0056] S20, chip mesa etching

[0057] S201. The cleaned In / InGaAs substrate is sequentially subjected to processes such as uniform coating, exposure, development, and film hardening, and a photoresist is used to form a pattern on the surface of the substrate to be etched;

[0058] S202, putting the above-mentioned substrate patterned with photoresist into the etching solution, and standing for etching for a certain period of time;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com