Macadimia nut base oil and preparation method thereof

A base oil and nut technology, applied in the field of skin care products, can solve the problems of poor sensory, poor stability, sticky texture, etc., and achieve the effect of enriching moisturizing ingredients, improving stability, and non-greasy texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

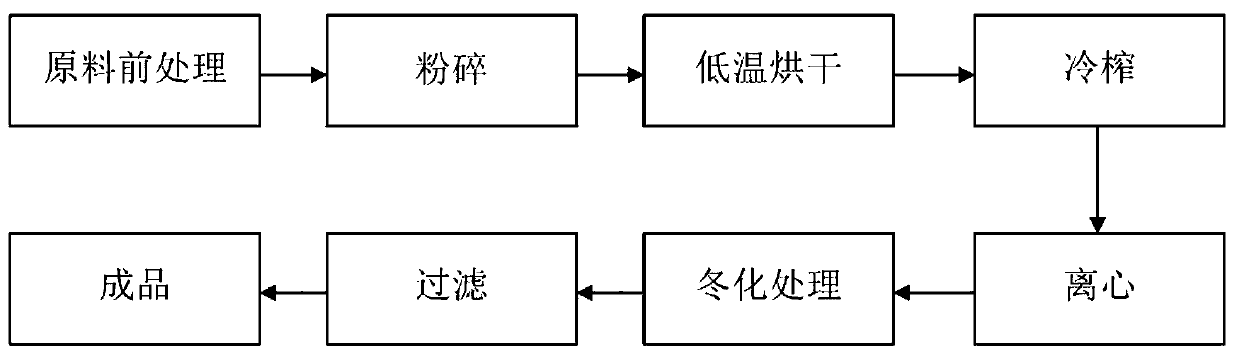

[0029] A preparation method of macadamia nut base oil, comprising the steps of:

[0030](1) Pre-treatment of raw materials: select freshly picked macadamia nuts with no damage on the outside as raw materials, remove the outer green skin, use a nut sheller to remove the hard shell of the nut, and remove blackened, insect-eaten and moldy nuts; The weight water content of macadamia nut kernels is 12-16%, the fat content is 70-73g / 100g, the acid value is 0.15-0.2mgKOH / g, the peroxide value is 0.01-0.016g / 100g, and the oleic acid content is 40-43g / 100g, the content of palmitoleic acid is 10-12g / 100g, the nuts are required to be full and complete, no shrunken kernels, no mildew, and the kernel yield rate is 13-15%;

[0031] (2) Crushing: crush the peeled and shelled nuts to complete particles with a diameter of 0.3-0.5 cm to obtain materials with uniform sizes;

[0032] (3) Low-temperature drying: Send the pulverized material into the drying room for drying treatment, set the dryi...

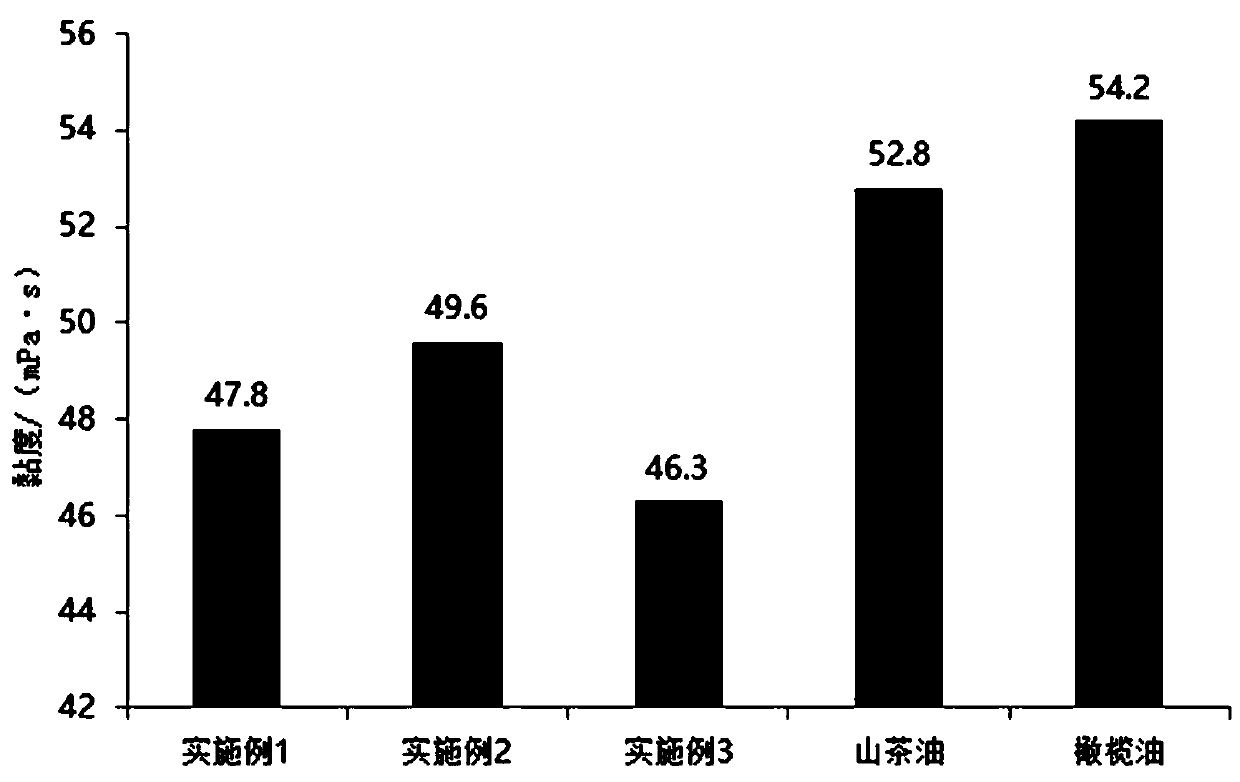

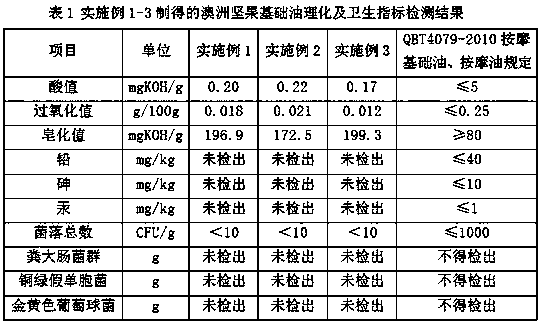

Embodiment 1

[0039] A preparation method of macadamia nut base oil, comprising the steps of:

[0040] (1) Pre-treatment of raw materials: select freshly picked macadamia nuts with no damage on the outside as raw materials, remove the outer green skin, use a nut sheller to remove the hard shell of the nut, and remove blackened, insect-eaten and moldy nuts; nuts The water content by weight is 14.2%, the fat content is 71.2g / 100g, the acid value is 0.17mgKOH / g, the peroxide value is 0.012g / 100g, the oleic acid content is 40.1g / 100g, and the palmitoleic acid content is 10.3g / 100g. Plump and complete, no flattened kernels, no mildew, the yield of kernels is 13.8%;

[0041] (2) Crushing: crush the peeled and shelled nuts to complete particles with a diameter of 0.3-0.5 cm to obtain materials with uniform sizes;

[0042] (3) Low-temperature drying: Send the crushed materials into the drying room for drying treatment. The thickness of the tiles is less than 0.5cm, and they are dried at 45°C for 5...

Embodiment 2

[0048] A preparation method of macadamia nut base oil, comprising the steps of:

[0049] (1) Pre-treatment of raw materials: select freshly picked macadamia nuts with no damage on the outside as raw materials, remove the outer green skin, use a nut sheller to remove the hard shell of the nut, and remove blackened, insect-eaten and moldy nuts; nuts The water content by weight is 12.5%, the fat content is 72.4g / 100g, the acid value is 0.2mgKOH / g, the peroxide value is 0.016g / 100g, the oleic acid content is 43.0g / 100g, and the palmitoleic acid content is 10.6g / 100g. Full and complete, no deflated kernels, no mildew, the yield of kernels is 14.7%;

[0050] (2) Crushing: crush the peeled and shelled nuts to complete particles with a diameter of 0.3-0.5 cm to obtain materials with uniform sizes;

[0051] (3) Low-temperature drying: Send the crushed materials into the drying room for drying treatment. The thickness of the tiles is less than 0.5cm, and they are dried at 45°C for 48 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| fat content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com