Vertical-structured LED chip of whole-surface reflector and preparation method of vertical-structured LED chip

A LED chip and vertical structure technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of easy leakage and low reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

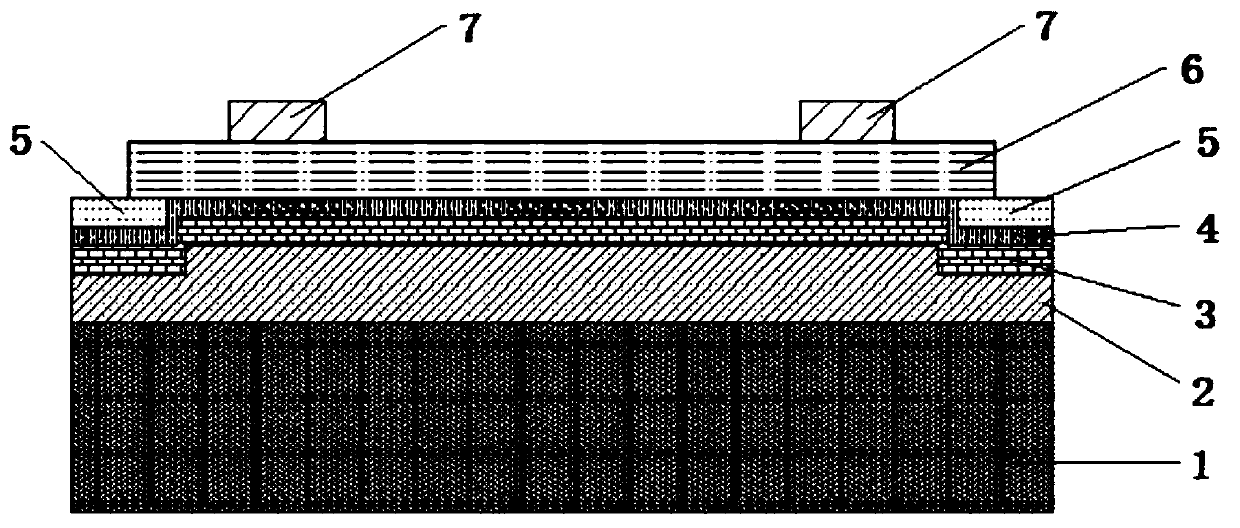

[0047]A method for preparing a vertical structure LED chip of a whole surface reflector, said method comprising the following steps:

[0048] Step S1, using MOCVD to grow an epitaxial layer on a substrate such as silicon, sapphire, SiC, etc., to form an LED epitaxial wafer;

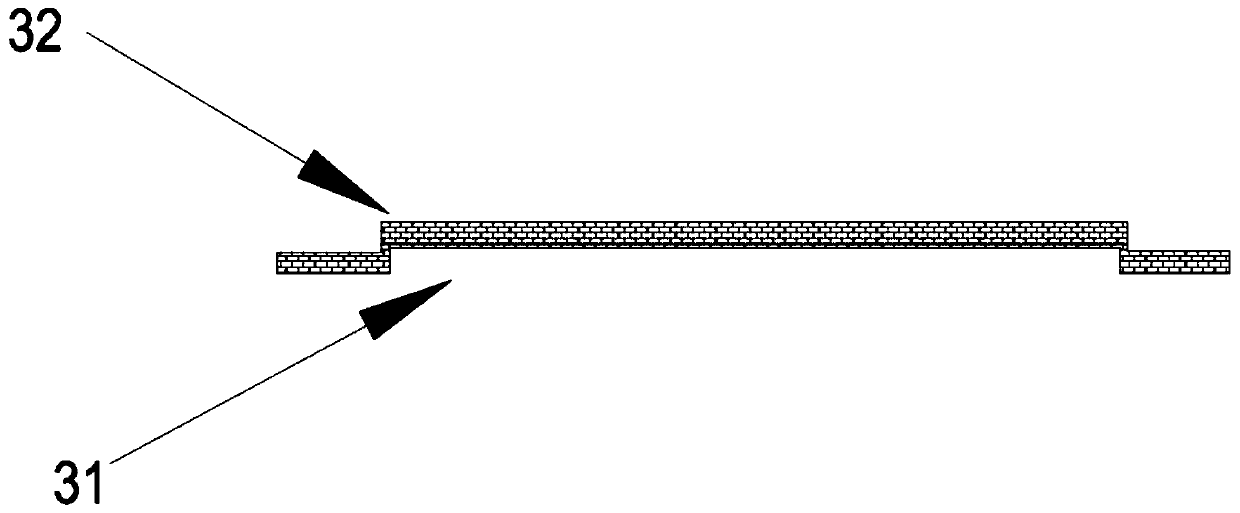

[0049] Step S2, growing an insulating layer on the LED epitaxial wafer by using PECVD or PVD or vapor deposition or spin coating;

[0050] Step S3, spin-coating photoresist on the insulating layer, and performing a photolithography process to form a square or rectangular ring;

[0051] Step S4, using a chemical etching or etching method to remove unnecessary insulating layers;

[0052] Step S5, using electron beam evaporation or PVD to cover the entire surface of the insulating layer and the epitaxial layer with a reflective metal layer;

[0053] Step S6, annealing the reflective metal layer to form a good ohmic contact and ensure a high reflectivity;

[0054] Step S7, after annealing, use electron bea...

Embodiment 1

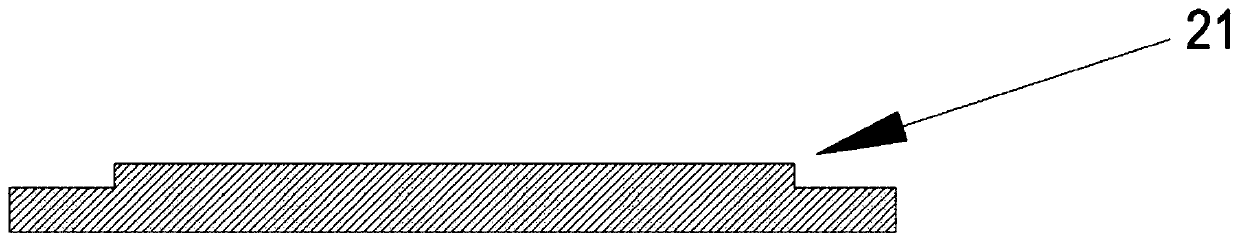

[0064] Using MOCVD epitaxial technology to grow LED epitaxial wafers with 2um-8um epitaxial layers on Si substrates;

[0065] Use acetone and isopropanol for organic cleaning for 5 minutes to remove organic dirt;

[0066] Then use SPM solution for pickling to remove inorganic metal dirt and organic dirt;

[0067] Rinse and dry, and use PECVD at 300 degrees to grow 400nm insulating SiO2;

[0068] Use positive photolithography technology to obtain a square photoresist ring with inner 1000um*1000um and outer 1030um*1030um;

[0069] BOE corrodes the SiO2 in the glue-free area until it is clean;

[0070] Remove photoresist, soak in dilute hydrochloric acid for 1-5 minutes, rinse with water and dry;

[0071] Electron beam evaporation on the entire surface of NiAg metal within Ni1nm, Ag100nm-300nm;

[0072] Ag annealing in N2 environment, 300-600 degrees, 10-600 seconds;

[0073] Electron beam evaporation TiPtTiPt protective layer and NiSn bonding metal layer, wherein, in the Ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com