SiO2-C nanosphere with core-shell structure and preparation method and application thereof

A technology of core-shell structure and nanospheres, which is applied in the direction of nanotechnology, nanotechnology, structural parts, etc. for materials and surface science. , easy to control, low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] Embodiments of the present invention provide a core-shell structure of SiO 2 -The preparation method of C nanosphere, it comprises:

[0024] S1. Mix the silicon source precursor and the carbon source precursor to obtain SiO 2 -C nanosphere precursor;

[0025] S2. SiO 2 - Sintering and carbonization of the C nanosphere precursor to obtain a sintered body;

[0026] S3. Partial SiO to sintered body 2 Corroded to obtain SiO 2 -C nanospheres.

[0027] The preparation method can obtain a core-shell structure with a controllable microstructure through simple hydrolysis, condensation, sintering carbonization and corrosion processes, and has the advantages of simple operation, low cost, low equipment requirements, and easy structure regulation.

[0028] The silicon source precursor includes at least one of tetraethylorthosilicate and tetrapropoxysilane. That is, it may be any one of tetraethyl orthosilicate and tetrapropoxysilane, or a mixture of the two.

[0029] The ca...

Embodiment 1

[0039] This embodiment provides a SiO 2 -C nanosphere, its preparation method is as follows:

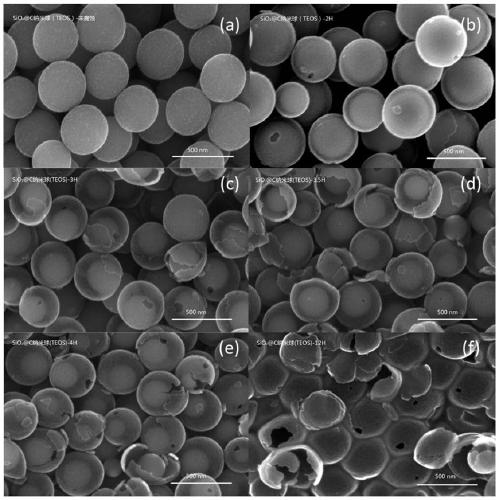

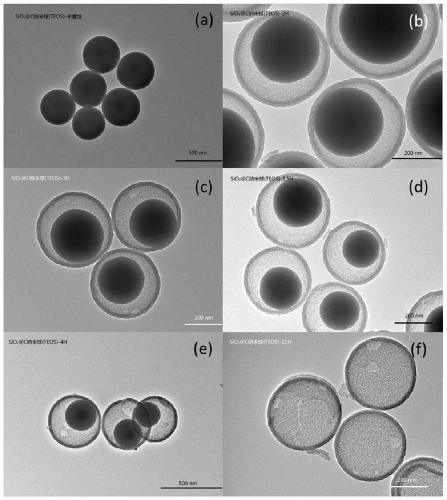

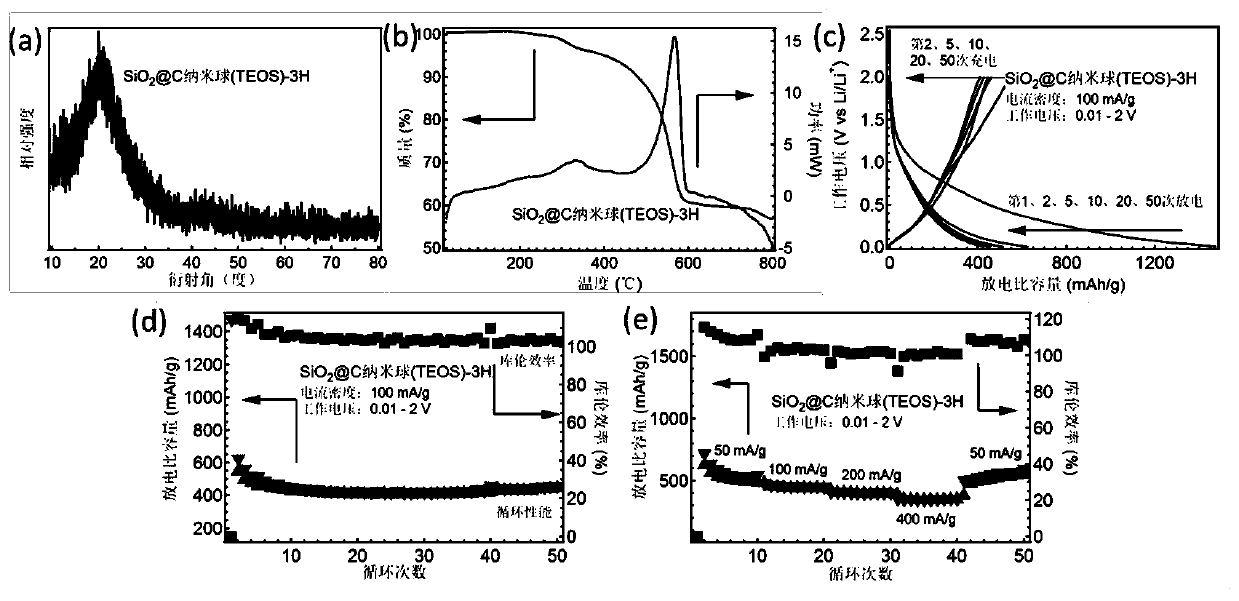

[0040] Put 140ml of ethanol, 40ml of deionized water, and 6ml of ammonia water (concentration 25%) into a beaker, stir thoroughly (at least 10 minutes), until a uniform solution is formed, add 6.92ml of tetraethyl orthosilicate (TEOS), and continue stirring for 15 Minutes, the solution turned milky white, finally added 0.8g resorcinol and 1.12ml formaldehyde (concentration 37%), stirred at 25°C for 24 hours to form a powder brown liquid, after centrifugal washing, a powder brown product was obtained, put into Dry in a vacuum oven at 60°C for 12 hours, put the dried sample into a quartz boat and keep it at 700°C for 5 hours under an argon atmosphere to obtain a black sample. Divide this sample into multiple parts, and take one part as a control , and the remaining parts were put into 5mol / L NaOH and corroded sequentially at 40°C for 2 hours, 3 hours, 3.5 hours, 4 hours and 12 hours. ...

Embodiment 2

[0043] This embodiment provides a SiO 2 -C nanosphere, its preparation method is as follows:

[0044] Put 140ml of ethanol, 40ml of deionized water, and 6ml of ammonia water (concentration 25%) into a beaker, stir well (at least 10 minutes), until a uniform solution is formed, add 6.92ml of tetrapropoxysilane (TPOS), and continue stirring for 15 minutes , finally add 0.8g resorcinol and 1.12ml formaldehyde (concentration 37%), stir at 25°C for 24 hours to form a brown liquid, after the brown liquid is centrifuged and washed, a brown product is obtained, and then put into a vacuum drying oven Dry at 60°C for 12 hours, place the dried sample in an argon atmosphere and raise the temperature to 700°C and keep it for 5 hours to obtain a black sample, put the sample in 5mol / L NaOH and corrode it at 40°C for 3 hours, the obtained The SEM and TEM of the samples are as in the description of the figures Figure 4 (a) and (c), its structure and lithium storage performance test are as f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com